SNLS484H February 2015 – June 2024 DP83867CR , DP83867IR

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Device Comparison

- 5 Pin Configuration and Functions

-

6 Specifications

- 6.1 Absolute Maximum Ratings

- 6.2 ESD Ratings

- 6.3 Recommended Operating Conditions

- 6.4 Thermal Information

- 6.5 Electrical Characteristics

- 6.6 Power-Up Timing

- 6.7 Reset Timing

- 6.8 MII Serial Management Timing

- 6.9 RGMII Timing

- 6.10 GMII Transmit Timing

- 6.11 GMII Receive Timing

- 6.12 100Mbps MII Transmit Timing

- 6.13 100Mbps MII Receive Timing #GUID-033E0939-17C5-4DC1-9C2C-A3998C85D8B1/SNLS4845065

- 6.14 10Mbps MII Transmit Timing

- 6.15 10Mbps MII Receive Timing

- 6.16 DP83867IR/CR Start of Frame Detection Timing

- 6.17 Timing Diagrams

- 6.18 Typical Characteristics

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3 Feature Description

- 7.4

Device Functional Modes

- 7.4.1 MAC Interfaces

- 7.4.2

Serial Management Interface

- 7.4.2.1

Extended Address Space Access

- 7.4.2.1.1 Write Address Operation

- 7.4.2.1.2 Read Address Operation

- 7.4.2.1.3 Write (No Post Increment) Operation

- 7.4.2.1.4 Read (No Post Increment) Operation

- 7.4.2.1.5 Write (Post Increment) Operation

- 7.4.2.1.6 Read (Post Increment) Operation

- 7.4.2.1.7 Example of Read Operation Using Indirect Register Access

- 7.4.2.1.8 Example of Write Operation Using Indirect Register Access

- 7.4.2.1

Extended Address Space Access

- 7.4.3

Auto-Negotiation

- 7.4.3.1 Speed and Duplex Selection - Priority Resolution

- 7.4.3.2 Master and Slave Resolution

- 7.4.3.3 Pause and Asymmetrical Pause Resolution

- 7.4.3.4 Next Page Support

- 7.4.3.5 Parallel Detection

- 7.4.3.6 Restart Auto-Negotiation

- 7.4.3.7 Enabling Auto-Negotiation Through Software

- 7.4.3.8 Auto-Negotiation Complete Time

- 7.4.3.9 Auto-MDIX Resolution

- 7.4.4 Loopback Mode

- 7.4.5 BIST Configuration

- 7.4.6 Cable Diagnostics

- 7.5 Programming

- 7.6

Register Maps

- 7.6.1 Basic Mode Control Register (BMCR)

- 7.6.2 Basic Mode Status Register (BMSR)

- 7.6.3 PHY Identifier Register #1 (PHYIDR1)

- 7.6.4 PHY Identifier Register #2 (PHYIDR2)

- 7.6.5 Auto-Negotiation Advertisement Register (ANAR)

- 7.6.6 Auto-Negotiation Link Partner Ability Register (ANLPAR) (BASE Page)

- 7.6.7 Auto-Negotiate Expansion Register (ANER)

- 7.6.8 Auto-Negotiation Next Page Transmit Register (ANNPTR)

- 7.6.9 Auto-Negotiation Next Page Receive Register (ANNPRR)

- 7.6.10 1000BASE-T Configuration Register (CFG1)

- 7.6.11 Status Register 1 (STS1)

- 7.6.12 Extended Register Addressing

- 7.6.13 1000BASE-T Status Register (1KSCR)

- 7.6.14 PHY Control Register (PHYCR)

- 7.6.15 PHY Status Register (PHYSTS)

- 7.6.16 MII Interrupt Control Register (MICR)

- 7.6.17 Interrupt Status Register (ISR)

- 7.6.18 Configuration Register 2 (CFG2)

- 7.6.19 Receiver Error Counter Register (RECR)

- 7.6.20 BIST Control Register (BISCR)

- 7.6.21 Status Register 2 (STS2)

- 7.6.22 LED Configuration Register 1 (LEDCR1)

- 7.6.23 LED Configuration Register 2 (LEDCR2)

- 7.6.24 LED Configuration Register (LEDCR3)

- 7.6.25 Configuration Register 3 (CFG3)

- 7.6.26 Control Register (CTRL)

- 7.6.27 Testmode Channel Control (TMCH_CTRL)

- 7.6.28 Robust Auto MDIX Timer Configuration Register (AMDIX_TMR_CFG)

- 7.6.29 Fast Link Drop Configuration Register (FLD_CFG)

- 7.6.30 Fast Link Drop Threshold Configuration Register (FLD_THR_CFG)

- 7.6.31 Configuration Register 4 (CFG4)

- 7.6.32 RGMII Control Register (RGMIICTL)

- 7.6.33 RGMII Control Register 2 (RGMIICTL2)

- 7.6.34 100BASE-TX Configuration (100CR)

- 7.6.35 Viterbi Module Configuration (VTM_CFG)

- 7.6.36 Skew FIFO Status (SKEW_FIFO)

- 7.6.37 Strap Configuration Status Register 1 (STRAP_STS1)

- 7.6.38 Strap Configuration Status Register 2 (STRAP_STS2)

- 7.6.39 BIST Control and Status Register 1 (BICSR1)

- 7.6.40 BIST Control and Status Register 2 (BICSR2)

- 7.6.41 BIST Control and Status Register 3 (BICSR3)

- 7.6.42 BIST Control and Status Register 4 (BICSR4)

- 7.6.43 Configuration for Receiver's Equalizer (CRE)

- 7.6.44 RGMII Delay Control Register (RGMIIDCTL)

- 7.6.45 ANA_LD_TXG_FINE_GAINSEL_AB (ALTFGAB)

- 7.6.46 ANA_LD_TXG_FINE_GAINSEL_CD (ALTFGCD)

- 7.6.47 ANA_LD_FILTER_TUNE_AB (ALFTAB)

- 7.6.48 ANA_LD_FILTER_TUNE_CD (ALFTCD)

- 7.6.49 Configuration of Receiver's LPF (CRLPF)

- 7.6.50 Enable Control of Receiver's Equalizer (ECRE)

- 7.6.51 PLL Clock-out Control Register (PLLCTL)

- 7.6.52 Sync FIFO Control (SYNC_FIFO_CTRL)

- 7.6.53 Loopback Configuration Register (LOOPCR)

- 7.6.54 DSP Configuration (DSP_CONFIG)

- 7.6.55 DSP Feedforward Equalizer Configuration (DSP_FFE_CFG)

- 7.6.56 Receive Configuration Register (RXFCFG)

- 7.6.57 Receive Status Register (RXFSTS)

- 7.6.58 Pattern Match Data Register 1 (RXFPMD1)

- 7.6.59 Pattern Match Data Register 2 (RXFPMD2)

- 7.6.60 Pattern Match Data Register 3 (RXFPMD3)

- 7.6.61 SecureOn Pass Register 2 (RXFSOP1)

- 7.6.62 SecureOn Pass Register 2 (RXFSOP2)

- 7.6.63 SecureOn Pass Register 3 (RXFSOP3)

- 7.6.64 Receive Pattern Register 1 (RXFPAT1)

- 7.6.65 Receive Pattern Register 2 (RXFPAT2)

- 7.6.66 Receive Pattern Register 3 (RXFPAT3)

- 7.6.67 Receive Pattern Register 4 (RXFPAT4)

- 7.6.68 Receive Pattern Register 5 (RXFPAT5)

- 7.6.69 Receive Pattern Register 6 (RXFPAT6)

- 7.6.70 Receive Pattern Register 7 (RXFPAT7)

- 7.6.71 Receive Pattern Register 8 (RXFPAT8)

- 7.6.72 Receive Pattern Register 9 (RXFPAT9)

- 7.6.73 Receive Pattern Register 10 (RXFPAT10)

- 7.6.74 Receive Pattern Register 11 (RXFPAT11)

- 7.6.75 Receive Pattern Register 12 (RXFPAT12)

- 7.6.76 Receive Pattern Register 13 (RXFPAT13)

- 7.6.77 Receive Pattern Register 14 (RXFPAT14)

- 7.6.78 Receive Pattern Register 15 (RXFPAT15)

- 7.6.79 Receive Pattern Register 16 (RXFPAT16)

- 7.6.80 Receive Pattern Register 17 (RXFPAT17)

- 7.6.81 Receive Pattern Register 18 (RXFPAT18)

- 7.6.82 Receive Pattern Register 19 (RXFPAT19)

- 7.6.83 Receive Pattern Register 20 (RXFPAT20)

- 7.6.84 Receive Pattern Register 21 (RXFPAT21)

- 7.6.85 Receive Pattern Register 22 (RXFPAT22)

- 7.6.86 Receive Pattern Register 23 (RXFPAT23)

- 7.6.87 Receive Pattern Register 24 (RXFPAT24)

- 7.6.88 Receive Pattern Register 25 (RXFPAT25)

- 7.6.89 Receive Pattern Register 26 (RXFPAT26)

- 7.6.90 Receive Pattern Register 27 (RXFPAT27)

- 7.6.91 Receive Pattern Register 28 (RXFPAT28)

- 7.6.92 Receive Pattern Register 29 (RXFPAT29)

- 7.6.93 Receive Pattern Register 30 (RXFPAT30)

- 7.6.94 Receive Pattern Register 31 (RXFPAT31)

- 7.6.95 Receive Pattern Register 32 (RXFPAT32)

- 7.6.96 Receive Pattern Byte Mask Register 1 (RXFPBM1)

- 7.6.97 Receive Pattern Byte Mask Register 2 (RXFPBM2)

- 7.6.98 Receive Pattern Byte Mask Register 3 (RXFPBM3)

- 7.6.99 Receive Pattern Byte Mask Register 4 (RXFPBM4)

- 7.6.100 Receive Pattern Control (RXFPATC)

- 7.6.101 I/O Configuration (IO_MUX_CFG)

- 7.6.102 GPIO Mux Control Register 1 (GPIO_MUX_CTRL1)

- 7.6.103 GPIO Mux Control Register 2 (GPIO_MUX_CTRL2)

- 7.6.104 GPIO Mux Control Register (GPIO_MUX_CTRL)

- 7.6.105 TDR General Configuration Register 1 (TDR_GEN_CFG1)

- 7.6.106 TDR Peak Locations Register 1 (TDR_PEAKS_LOC_1)

- 7.6.107 TDR Peak Locations Register 2 (TDR_PEAKS_LOC_2)

- 7.6.108 TDR Peak Locations Register 3 (TDR_PEAKS_LOC_3)

- 7.6.109 TDR Peak Locations Register 4 (TDR_PEAKS_LOC_4)

- 7.6.110 TDR Peak Locations Register 5 (TDR_PEAKS_LOC_5)

- 7.6.111 TDR Peak Locations Register 6 (TDR_PEAKS_LOC_6)

- 7.6.112 TDR Peak Locations Register 7 (TDR_PEAKS_LOC_7)

- 7.6.113 TDR Peak Locations Register 8 (TDR_PEAKS_LOC_8)

- 7.6.114 TDR Peak Locations Register 9 (TDR_PEAKS_LOC_9)

- 7.6.115 TDR Peak Locations Register 10 (TDR_PEAKS_LOC_10)

- 7.6.116 TDR Peak Amplitudes Register 1 (TDR_PEAKS_AMP_1)

- 7.6.117 TDR Peak Amplitudes Register 2 (TDR_PEAKS_AMP_2)

- 7.6.118 TDR Peak Amplitudes Register 3 (TDR_PEAKS_AMP_3)

- 7.6.119 TDR Peak Amplitudes Register 4 (TDR_PEAKS_AMP_4)

- 7.6.120 TDR Peak Amplitudes Register 5 (TDR_PEAKS_AMP_5)

- 7.6.121 TDR Peak Amplitudes Register 6 (TDR_PEAKS_AMP_6)

- 7.6.122 TDR Peak Amplitudes Register 7 (TDR_PEAKS_AMP_7)

- 7.6.123 TDR Peak Amplitudes Register 8 (TDR_PEAKS_AMP_8)

- 7.6.124 TDR Peak Amplitudes Register 9 (TDR_PEAKS_AMP_9)

- 7.6.125 TDR Peak Amplitudes Register 10 (TDR_PEAKS_AMP_10)

- 7.6.126 TDR General Status (TDR_GEN_STATUS)

- 7.6.127 TDR Peak Sign AB (TDR_PEAK_SIGN_A_B)

- 7.6.128 TDR Peak Sign CD (TDR_PEAK_SIGN_C_D)

- 8 Application and Implementation

- 9 Device and Documentation Support

- 10Revision History

- 11Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- RGZ|48

- PAP|64

Thermal pad, mechanical data (Package|Pins)

Orderable Information

7.4.2 Serial Management Interface

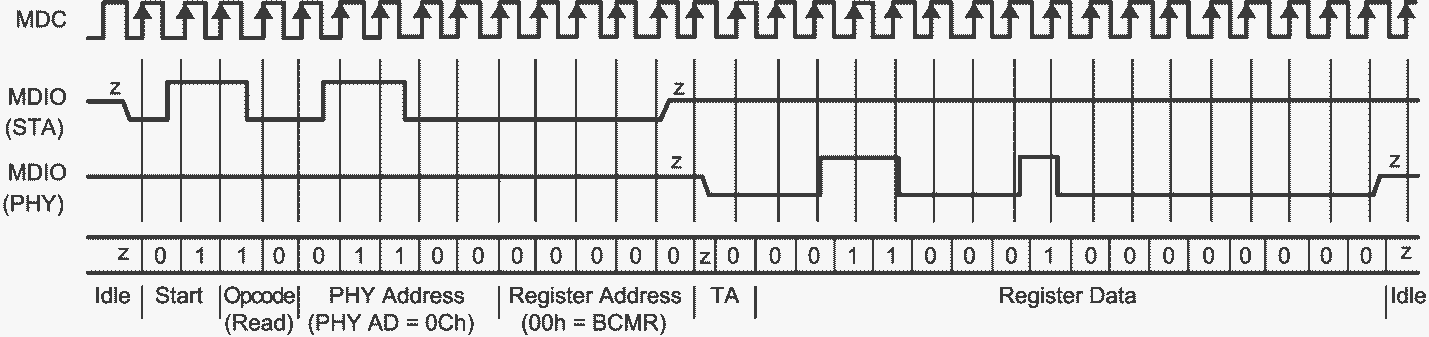

The Serial Management Interface (SMI), provides access to the DP83867 internal register space for status information and configuration. The SMI is compatible with IEEE 802.3-2002 clause 22. The implemented register set consists of the registers required by the IEEE 802.3, plus several others to provide additional visibility and controllability of the DP83867 device.

The SMI includes the MDC management clock input and the management MDIO data pin. The MDC clock is sourced by the external management entity, also called Station (STA), and can run at a maximum clock rate of 25MHz. MDC is not expected to be continuous, and can be turned off by the external management entity when the bus is idle.

The MDIO is sourced by the external management entity and by the PHY. The data on the MDIO pin is latched on the rising edge of the MDC clock. The MDIO pin requires a pullup resistor (2.2kΩ) which, during IDLE and turnaround, pulls MDIO high.

Up to 16 PHYs can share a common SMI bus. To distinguish between the PHYs, a 4-bit address is used. During power-up reset, the DP83867 latches the PHY_ADD configuration pins to determine its address. The DP83867IRPAP 64-pin variant can support up to 32 PHYs and uses a 5-bit address.

The management entity must not start an SMI transaction in the first cycle after power-up reset. To maintain valid operation, the SMI bus must remain inactive at least one MDC cycle after hard reset is deasserted. In normal MDIO transactions, the register address is taken directly from the management-frame reg_addr field, thus allowing direct access to 32 16-bit registers (including those defined in IEEE 802.3 and vendor specific). The data field is used for both reading and writing. The Start code is indicated by a <01> pattern. This pattern makes sure that the MDIO line transitions from the default idle line state. Turnaround is defined as an idle bit time inserted between the Register Address field and the Data field. To avoid contention during a read transaction, no device may actively drive the MDIO signal during the first bit of turnaround. The addressed DP83867 drives the MDIO with a zero for the second bit of turnaround and follows this with the required data. Figure 7-9 shows the timing relationship between MDC and the MDIO as driven and received by the Station (STA) and the DP83867 (PHY) for a typical register read access.

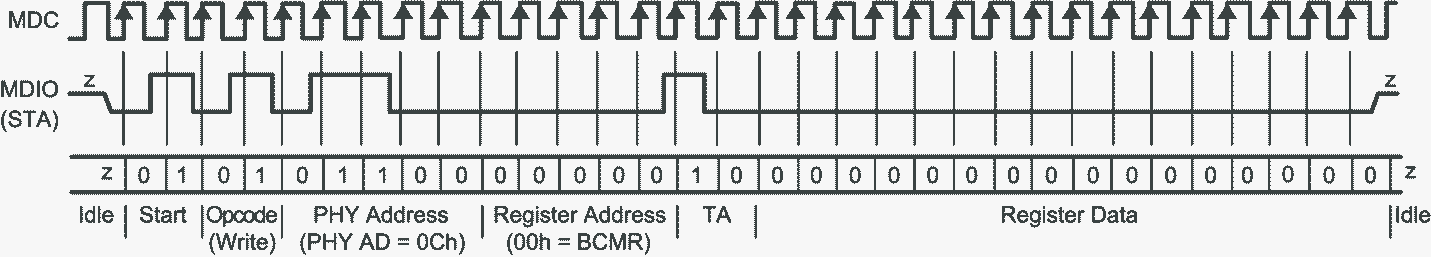

For write transactions, the station-management entity writes data to the addressed DP83867, thus eliminating the requirement for MDIO turnaround. The turnaround time is filled by the management entity by inserting <10>. Figure 7-9 shows the timing relationship for a typical MII register write access. The frame structure and general read and write transactions are shown in Table 7-1, Figure 7-9, and Figure 7-10.

| TYPICAL MDIO FRAME FORMAT | <idle><start><op code><device addr><reg addr><turnaround><data<<idle> |

|---|---|

| Read Operation | <idle><01><10><AAAA><RRRR><Z0><xxxx xxxx xxxx xxxx><idle> |

| Write Operation | <idle><01<01><AAAA><RRRR><10><xxxx xxxx xxxx xxxx><idle> |

Figure 7-9 Typical MDC/MDIO Read Operation

Figure 7-9 Typical MDC/MDIO Read Operation Figure 7-10 Typical MDC/MDIO Write Operation

Figure 7-10 Typical MDC/MDIO Write Operation