SLOS879B April 2014 – September 2016 DRV2625

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Parameter Measurement Information

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3

Feature Description

- 8.3.1 Support for ERM and LRA Actuators

- 8.3.2 Smart-Loop Architecture

- 8.3.3 Open-Loop Operation

- 8.3.4 Flexible Front-End Interface

- 8.3.5 Noise Gate Control

- 8.3.6 Edge Rate Control

- 8.3.7 Constant Vibration Strength

- 8.3.8 Battery Voltage Reporting

- 8.3.9 Ultra Low-Power Shutdown

- 8.3.10 Automatic Go-To-Stand-by (Low Power)

- 8.3.11 I2C Watchdog Timer

- 8.3.12 Device Protection

- 8.3.13 POR

- 8.3.14 Silicon Revision Control

- 8.3.15 Support for LRA and ERM Actuators

- 8.3.16 Multi-Purpose Pin Functionality

- 8.3.17 Automatic Transition to Standby State

- 8.3.18 Automatic Brake into Standby

- 8.3.19 Battery Monitoring and Power Preservation

- 8.4 Device Functional Modes

- 8.5 Operation During Exceptional Conditions

- 8.6

Programming

- 8.6.1 Auto-Resonance Engine Programming for the LRA

- 8.6.2 Automatic-Level Calibration Programming

- 8.6.3 I2C Interface

- 8.6.4 Programming for Open-Loop Operation

- 8.6.5 Programming for Closed-Loop Operation

- 8.6.6 Diagnostics Routine

- 8.6.7 Calibration Routine

- 8.6.8 Waveform Playback Programming

- 8.6.9 Waveform Setup and Playback

- 8.7

Register Map

- 8.7.1 Address: 0x00

- 8.7.2 Address: 0x01

- 8.7.3 Address: 0x02

- 8.7.4 Address: 0x03

- 8.7.5 Address: 0x04

- 8.7.6 Address: 0x05

- 8.7.7 Address: 0x06

- 8.7.8 Address: 0x07

- 8.7.9 Address: 0x08

- 8.7.10 Address: 0x09

- 8.7.11 Address: 0x0A

- 8.7.12 Address: 0x0B

- 8.7.13 Address: 0x0C

- 8.7.14 Address: 0x0D

- 8.7.15 Address: 0x0E

- 8.7.16 Address: 0x0F

- 8.7.17 Address: 0x10

- 8.7.18 Address: 0x11

- 8.7.19 Address: 0x12

- 8.7.20 Address: 0x13

- 8.7.21 Address: 0x14

- 8.7.22 Address: 0x15

- 8.7.23 Address: 0x16

- 8.7.24 Address: 0x17

- 8.7.25 Address: 0x18

- 8.7.26 Address: 0x19

- 8.7.27 Address: 0x1A

- 8.7.28 Address: 0x1B

- 8.7.29 Address: 0x1C

- 8.7.30 Address: 0x1D

- 8.7.31 Address: 0x1F

- 8.7.32 Address: 0x20

- 8.7.33 Address: 0x21

- 8.7.34 Address: 0x22

- 8.7.35 Address: 0x23

- 8.7.36 Address: 0x24

- 8.7.37 Address: 0x25

- 8.7.38 Address: 0x26

- 8.7.39 Address: 0x27

- 8.7.40 Address: 0x28

- 8.7.41 Address: 0x29

- 8.7.42 Address: 0x2A

- 8.7.43 Address: 0x2C

- 8.7.44 Address: 0x2E

- 8.7.45 Address: 0x2F

- 8.7.46 Address: 0x30

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- YFF|9

Thermal pad, mechanical data (Package|Pins)

Orderable Information

9 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

9.1 Application Information

The typical application for a haptic driver is in a touch-enabled system that already has an application processor which makes the decision on when to execute haptic effects.

The DRV2625 device can be used fully with I2C communications (either using RTP or the memory interface). A system designer can chose to use external triggers to play low-latency effects (such as from a physical button). Figure 88 and Figure 89 show typical haptic system implementations. The system designer should not use the internal regulator (REG) to power any external load.

Figure 88. I2C Control with Optional External Trigger

Figure 88. I2C Control with Optional External Trigger

Figure 89. I2C Control with Optional Interrupt Pin

Figure 89. I2C Control with Optional Interrupt Pin

Table 50. Recommended External Components

| COMPONENT | DESCRIPTION | SPECIFICATION | TYPICAL VALUE |

|---|---|---|---|

| C(VDD) | Input capacitor | Capacitance | 0.1 µF |

| C(REG) | Regulator capacitor | Capacitance | 0.1 µF |

| R(PU) | Pull-up resistor | Resistance | 2.2 kΩ |

9.2 Typical Application

A typical application of the DRV2625 device is in a system that has external buttons which fire different haptic effects when pressed. Figure 90, Figure 91 and Figure 92 show typical schematics of such a system. The buttons can be physical buttons, capacitive-touch buttons, or GPIO signals coming from the touch-screen system.

Effects in this type of system are programmable.

Figure 90. Typical Application Schematic Without External Trigger or Interrupt Pin

Figure 90. Typical Application Schematic Without External Trigger or Interrupt Pin

Figure 91. Typical Application Schematic With External Trigger

Figure 91. Typical Application Schematic With External Trigger

Figure 92. Typical Application Schematic With Interrupt Pin

Figure 92. Typical Application Schematic With Interrupt Pin

9.2.1 Design Requirements

For this design example, use the values listed in Table 51 as the input parameters.

Table 51. Design Parameters

| DESIGN PARAMETER | EXAMPLE VALUE |

|---|---|

| Interface | I2C, external trigger |

| Actuator type | LRA, ERM |

| Input power source | Li-ion/Li-polymer, 5-V boost |

9.2.2 Detailed Design Procedure

9.2.2.1 Actuator Selection

The actuator decision is based on many factors including cost, form factor, vibration strength, power-consumption requirements, haptic sharpness requirements, reliability, and audible noise performance. The actuator selection is one of the most important design considerations of a haptic system and therefore the actuator should be the first component to consider when designing the system. The following sections list the basics of ERM and LRA actuators.

9.2.2.1.1 Eccentric Rotating-Mass Motors (ERM)

Eccentric rotating-mass motors (ERMs) are typically DC-controlled motors of the bar or coin type. ERMs can be driven in the clockwise direction or counter-clockwise direction depending on the polarity of voltage across the two pins. Bidirectional drive is made possible in a single-supply system by differential outputs that are capable of sourcing and sinking current. This feature helps eliminate long vibration tails which are undesirable in haptic feedback systems.

Figure 93. Motor Spin Direction in ERM Motors

Figure 93. Motor Spin Direction in ERM Motors

Another common approach to driving DC motors is the concept of overdrive voltage. To overcome the inertia of the mass of the motor, these motors are often overdriven for a short amount of time before returning to the rated voltage of the motor to sustain the rotation of the motor. Overdrive is also used to stop (or brake) a motor quickly. Refer the data sheet of the motor for safe and reliable overdrive voltage and duration.

9.2.2.1.2 Linear Resonance Actuators (LRA)

Linear resonant actuators (LRAs) vibrate optimally at the resonant frequency. LRAs have a high-Q frequency response because of a rapid drop in vibration performance at the offsets of 3 to 5 Hz from the resonant frequency. Many factors also cause a shift or drift in the resonant frequency of the actuator such as temperature, aging, the mass of the product to which the LRA is mounted, and in the case of a portable product, the manner in which the product is held. Furthermore, as the actuator is driven to the maximum allowed voltage, many LRAs will shift several hertz in frequency because of mechanical compression. All of these factors make a real-time tracking auto-resonant algorithm critical when driving LRA to achieve consistent, optimized performance.

Figure 94. Typical LRA Response

Figure 94. Typical LRA Response

9.2.2.1.2.1 Auto-Resonance Engine for LRA

The DRV2625 auto-resonance engine tracks the resonant frequency of an LRA in real time effectively locking into the resonance frequency after half a cycle. If the resonant frequency shifts in the middle of a waveform for any reason, the engine tracks the frequency from cycle to cycle. The auto resonance engine accomplishes the tracking by constantly monitoring the back-EMF of the actuator. Note that the auto resonance engine is not affected by the auto-calibration process which is only used for level calibration. No calibration is required for the auto resonance engine.

9.2.2.2 Capacitor Selection

The DRV2625 device has a switching output stage which pulls transient currents through the VDD pin. Placing a 0.1-µF low equivalent-series-resistance (ESR) supply-bypass capacitor of the X5R or X7R type near the VDD supply pin is recommended for proper operation of the output driver and the digital portion of the device. Place a 0.1-µF X5R or X7R-type capacitor from the REG pin to ground.

9.2.2.3 Interface Selection

The DRV2625 device was designed with a default configuration that supports a wide variety of LRA actuators. If an actuator compatible with the default of the device is selected, then the SimpleDrive can be used without the use of I2C interface. For this case, the user has 3 options available: controlling the NRST and TRIG/INTZ pin independently (4 pin interface: VDD, GND, NRST, TRIG/INTZ), shorting NRST with TRIG/INTZ pin and controlling them with a single GPIO (3 pin interface: VDD, GND, TRIG), or shorting NRST, TRIG/INTZ and VDD together (2 pin interface: VDD, GND). Note that for the 2-pin interface, the VDD signal must ramp faster than the startup time (about 500 µs) otherwise a UVLO condition will be detected which will prevent the device from playing the desired waveform

The I2C interface is required to configure the device. The device can be used fully with this interface with either RTP or internal memory. The advantage of using this interface is that no additional GPIO (for the TRIG/INTZ pin) is required for firing effects. Therefore the TRIG/INTZ pin can be connected to GND. Using the external trigger pin has the advantage that no I2C transaction is required to fire the pre-loaded effect, which is a good choice for interfacing with a button.

9.2.2.4 Power Supply Selection

The DRV2625 device supports a wide range of voltages in the input. Ensuring that the battery voltage is high enough to support the desired vibration strength with the selected actuator is an important design consideration. The typical application uses Li-ion or Li-polymer batteries which provide enough voltage headroom to drive most common actuators.

If very strong vibrations are desired, a boost converter can be placed between the power supply and the VDD pin to provide a constant voltage with a healthy headroom (5-V rails are common in some systems) which is particularly true if 2 AA batteries in series are being used to power the system.

9.2.3 Application Curves

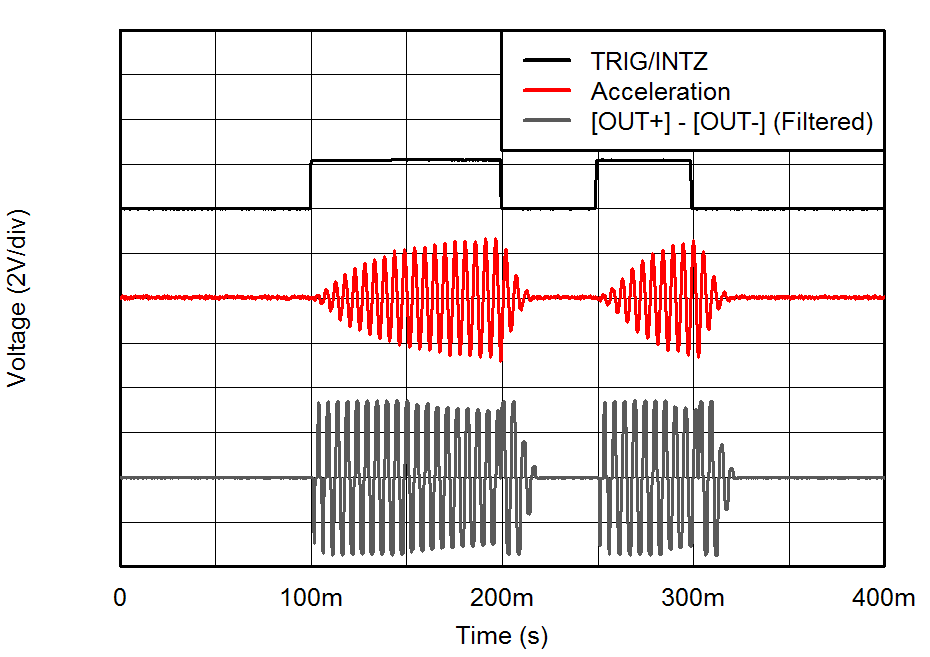

Figure 95. LRA SimpleDrive

Figure 95. LRA SimpleDrive

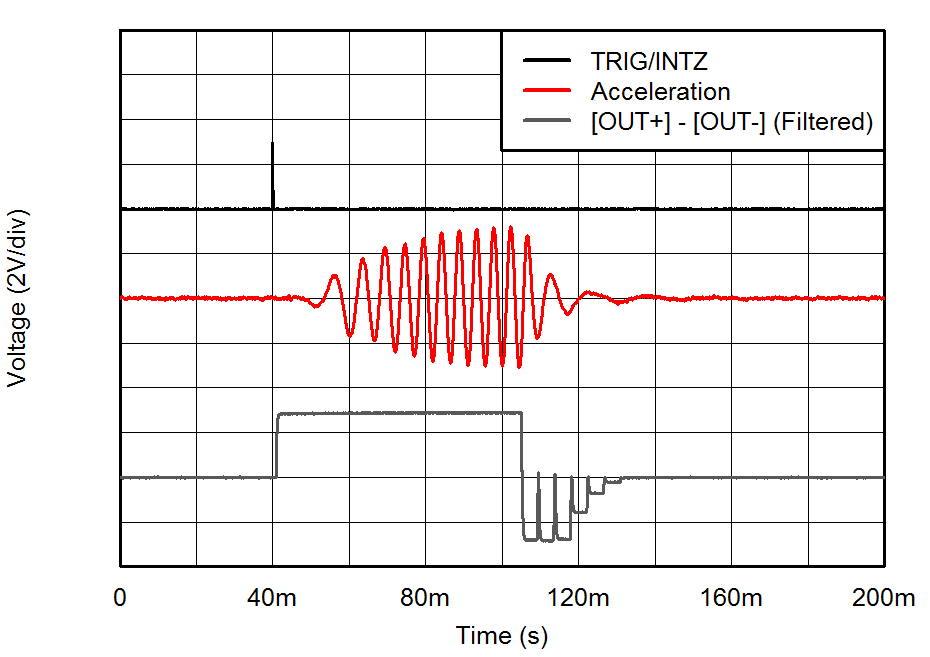

Figure 96. ERM Open-Loop Drive with Automatic Brake

Figure 96. ERM Open-Loop Drive with Automatic Brake

9.3 Initialization Set Up

9.3.1 Initialization Procedure

- After power-up, wait at least 1 ms before the DRV2625 device accepts I2C commands.

- Assert the NRST pin (logic high). The NRST pin can be asserted any time during or after the wait period.

- Write the MODE parameter (address 0x01) to value 0x00 to remove the device from standby mode.

- Run auto-calibration to configure the DRV2625 device for the desired actuator. Alternatively, rewrite the results from a previous calibration.

- If using the embedded ROM library, write the library selection bit (LIB_SEL)to select a library.

NOTE

The DRV2625 device defaults to closed-loop mode with external trigger option selected in the level (enable) configuration and in RTP mode. To use other modes and features, refer to the regiter map.

9.3.2 Typical Usage Examples

9.3.2.1 Play a Waveform or Waveform Sequence from the ROM Waveform Memory

- Initialize the device as listed in the Initialization Procedure section.

- Select the desired TRIG/INTZ pin function by changing the TRIG_PIN_FUNC parameter.

- Identify the waveform index to be played and populate the waveform sequencer.

- Trigger the waveform using the desired trigger method (GO bit, or external trigger). Note that if using the interrupt functionality, only the GO bit can be used to trigger the process.

- Device will automatically go into standby upon completion of the playback

9.3.2.2 Play a Real-Time Playback (RTP) Waveform

- Initialize the device as shown in the Initialization Procedure section.

- Write the desired drive amplitude to the real-time playback input register RTP_INPUT[7:0].

- Trigger the waveform using the desired trigger method (GO bit, or external trigger). Note that if using the interrupt functionality, only the GO bit can be used to trigger the process.

- Continue writing to the RTP_INPUT[7:0] if/when desired to achieve the desired haptic effect.

- Send a stop trigger using the desired trigger method (GO bit, or external trigger). Note that if using the interrupt functionality, only the GO bit can be used to trigger the process.

- Device will automatically go into standby upon completion of the playback