SLOSE83A March 2023 – January 2025 DRV8952

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Pin Configuration and Functions

- 5 Specifications

- 6 Detailed Description

- 7 Application and Implementation

- 8 Package Thermal Considerations

- 9 Device and Documentation Support

- 10Revision History

- 11Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

Thermal pad, mechanical data (Package|Pins)

Orderable Information

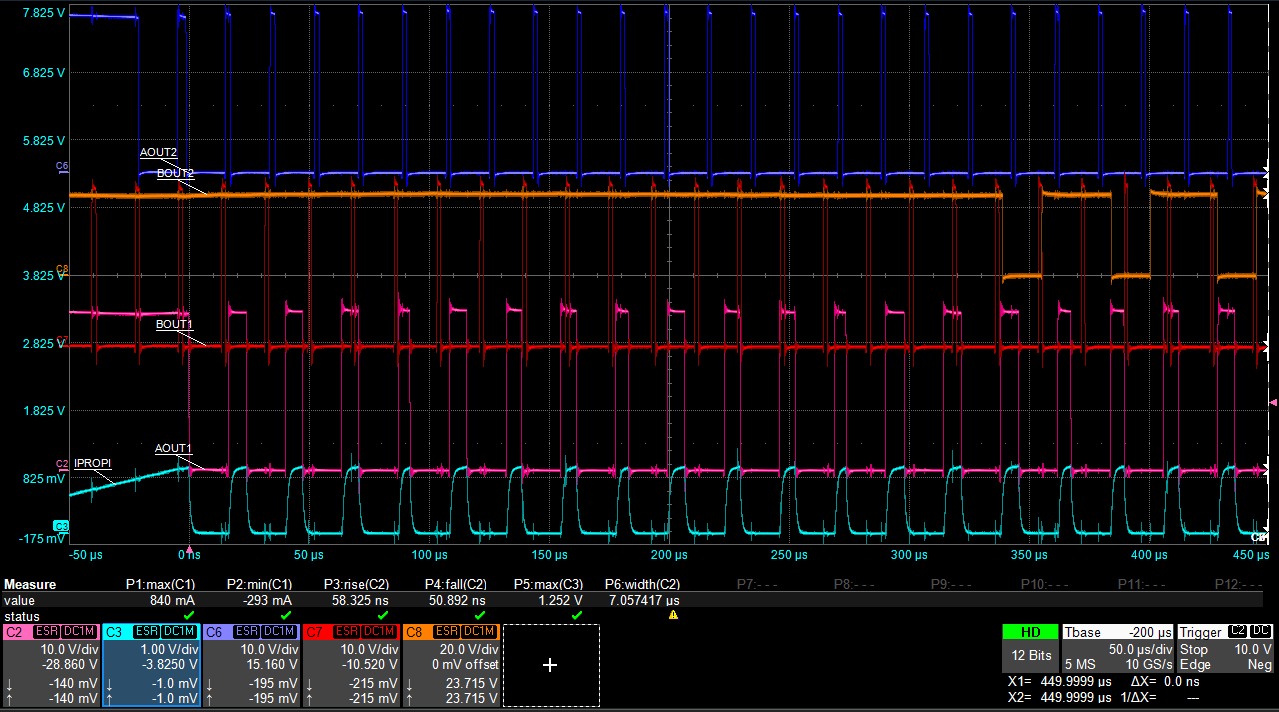

7.1.1.3 Application Performance Plots

Figure 7-2 Driving four loads simultaneously.

Figure 7-2 Driving four loads simultaneously. Traces from top to bottom: OUT1, OUT2, OUT3, OUT4, IPROPI1

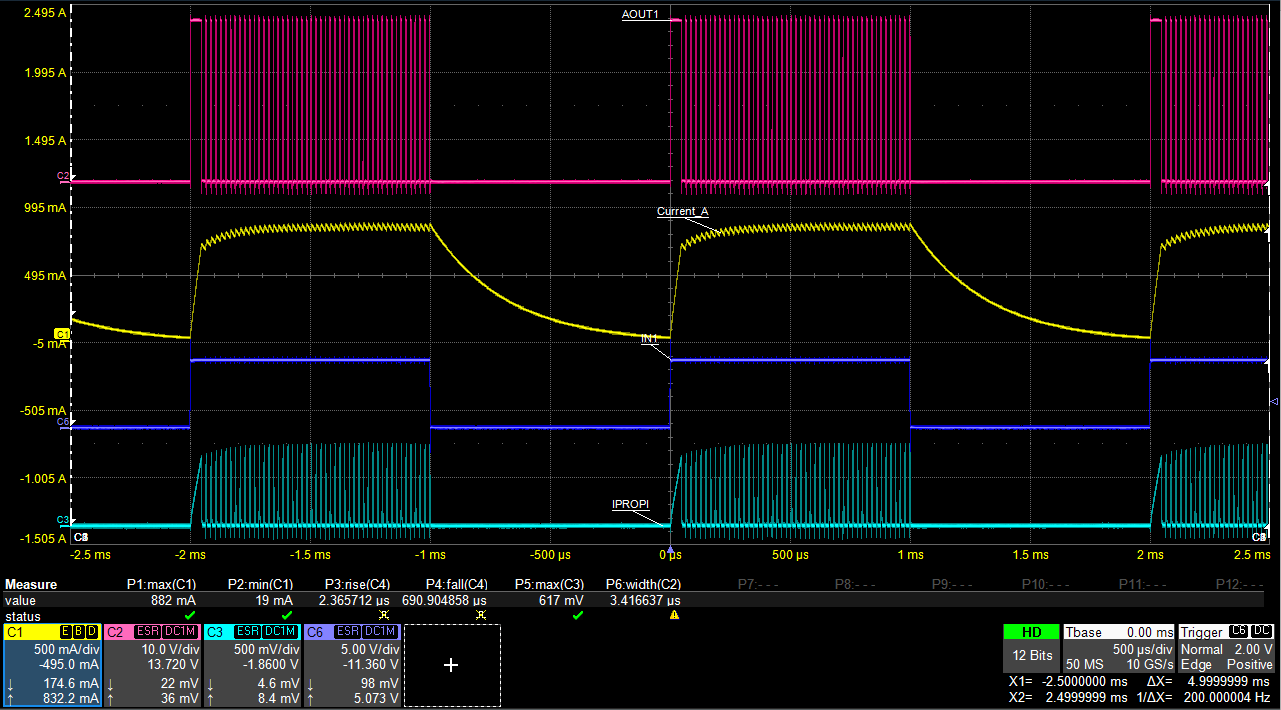

Figure 7-3 Current regulation with IPROPI Output. Traces from top to bottom: OUT1, IOUT1, IN1, IPROPI1

Figure 7-3 Current regulation with IPROPI Output. Traces from top to bottom: OUT1, IOUT1, IN1, IPROPI1