SNLS456D March 2016 – October 2019 DS250DF410

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Description (continued)

- 6 Pin Configuration and Functions

-

7 Specifications

- 7.1 Absolute Maximum Ratings

- 7.2 ESD Ratings

- 7.3 Recommended Operating Conditions

- 7.4 Thermal Information

- 7.5 Electrical Characteristics

- 7.6 Timing Requirements, Retimer Jitter Specifications

- 7.7 Timing Requirements, Retimer Specifications

- 7.8 Timing Requirements, Recommended Calibration Clock Specifications

- 7.9 Recommended SMBus Switching Characteristics (Slave Mode)

- 7.10 Recommended SMBus Switching Characteristics (Master Mode)

- 7.11 Recommended JTAG Switching Characteristics

- 7.12 Typical Characteristics

-

8 Detailed Description

- 8.1 Overview

- 8.2 Functional Block Diagram

- 8.3

Feature Description

- 8.3.1 Device Data Path Operation

- 8.3.2 Signal Detect

- 8.3.3 Continuous Time Linear Equalizer (CTLE)

- 8.3.4 Variable Gain Amplifier (VGA)

- 8.3.5 Cross-Point Switch

- 8.3.6 Decision Feedback Equalizer (DFE)

- 8.3.7 Clock and Data Recovery (CDR)

- 8.3.8 Calibration Clock

- 8.3.9 Differential Driver with FIR Filter

- 8.3.10 Debug Features

- 8.3.11 Interrupt Signals

- 8.3.12 JTAG Boundary Scan

- 8.4 Device Functional Modes

- 8.5 Programming

- 8.6 Register Maps

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- ABM|101

Thermal pad, mechanical data (Package|Pins)

Orderable Information

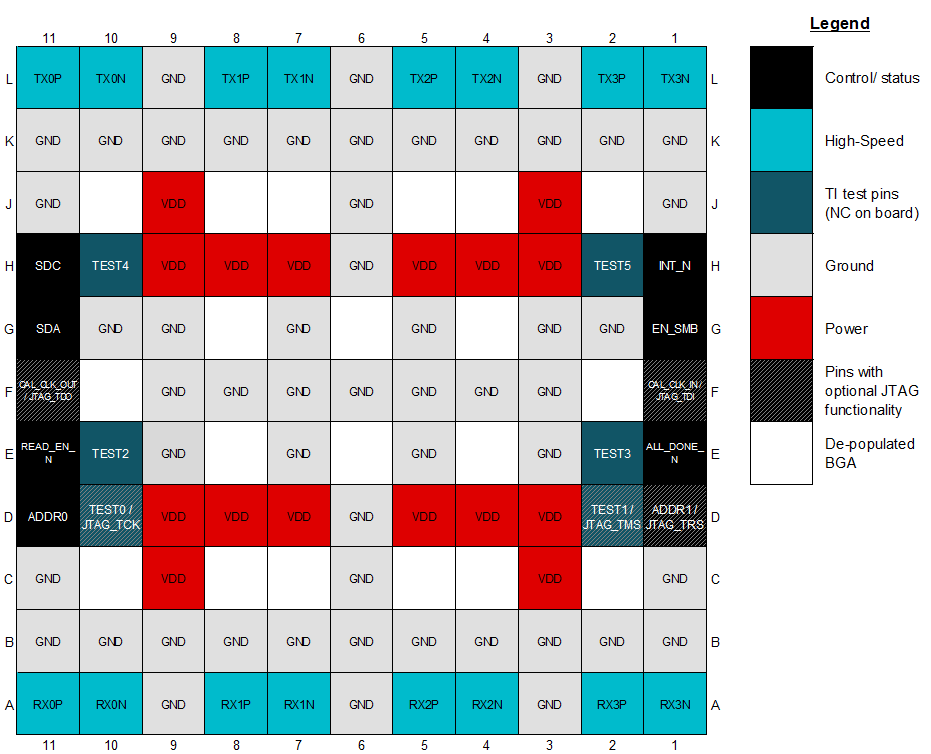

6 Pin Configuration and Functions

ABM Package

101-Pin FC/CSP

Top View

Pin Functions

| PIN | TYPE | INTERNAL

PULL-UP/ PULL-DOWN |

DESCRIPTION | |

|---|---|---|---|---|

| NAME | NO. | |||

| HIGH SPEED DIFFERENTIAL I/Os | ||||

| RX0N | A10 | Input | None | Inverting and non-inverting differential inputs to the equalizer. An on-chip 100-Ω termination resistor connects RXP to RXN. These inputs need to be AC coupled.(1) |

| RX0P | A11 | Input | None | |

| RX1N | A7 | Input | None | Inverting and non-inverting differential inputs to the equalizer. An on-chip 100-Ω termination resistor connects RXP to RXN. These inputs need to be AC coupled.(1) |

| RX1P | A8 | Input | None | |

| RX2N | A4 | Input | None | Inverting and non-inverting differential inputs to the equalizer. An on-chip 100-Ω termination resistor connects RXP to RXN. These inputs need to be AC coupled.(1) |

| RX2P | A5 | Input | None | |

| RX3N | A1 | Input | None | Inverting and non-inverting differential inputs to the equalizer. An on-chip 100-Ω termination resistor connects RXP to RXN. These inputs need to be AC coupled.(1) |

| RX3P | A2 | Input | None | |

| TX0N | L10 | Output | None | Inverting and non-inverting 50-Ω driver outputs. Compatible with AC-coupled differential inputs. These outputs need to be AC coupled.(1) |

| TX0P | L11 | Output | None | |

| TX1N | L7 | Output | None | Inverting and non-inverting 50-Ω driver outputs. Compatible with AC-coupled differential inputs. These outputs need to be AC coupled.(1) |

| TX1P | L8 | Output | None | |

| TX2N | L4 | Output | None | Inverting and non-inverting 50-Ω driver outputs. Compatible with AC-coupled differential inputs. These outputs need to be AC coupled.(1) |

| TX2P | L5 | Output | None | |

| TX3N | L1 | Output | None | Inverting and non-inverting 50-Ω driver outputs. Compatible with AC-coupled differential inputs. These outputs need to be AC coupled.(1) |

| TX3P | L2 | Output | None | |

| CALIBRATION CLOCK PINS | ||||

| CAL_CLK_IN/

JTAG_TDI |

F1 | Input, 2.5V CMOS | Weak pull-up in JTAG mode. Weak pull-down in functional mode | 25 MHz (±100 PPM) 2.5-V single-ended clock from external oscillator. No stringent phase noise or jitter requirements on this clock. Used to calibrate VCO frequency range.

In JTAG mode (EN_SMB = 1 kΩ to GND), this is JTAG Test Data In (TDI). |

| CAL_CLK_OUT/

JTAG_TDO |

F11 | Output, 2.5V CMOS | None | 2.5-V buffered replica of calibration clock input (pin E1) for connecting multiple devices in a daisy-chained fashion.

In JTAG mode (EN_SMB = 1 kΩ to GND), this is JTAG Test Data Out (TDO). |

| SYSTEM MANAGEMENT BUS (SMBus) PINS | ||||

| ADDR0 | D11 | Input, 4-level | None | 4-level strap pins used to set the SMBus address of the device. The pin state is read on power-up. The multi-level nature of these pins allows for 16 unique device addresses. The four strap options include:

0: 1 kΩ to GND R: 20 kΩ to GND F: Float 1: 1 kΩ to VDD Refer to Device SMBus Address for more information. In JTAG mode (EN_SMB = 1 kΩ to GND), ADDR1 is JTAG Test Reset (TRS). |

| ADDR1/JTAG_TRS | D1 | Input, 4-level | Weak pull-up in JTAG mode | |

| EN_SMB | G1 | Input, 4-level | None | Four-level 2.5-V input used to select between SMBus master mode (float) and SMBus slave mode (high). The four defined levels are:

0: 1 kΩ to GND - JTAG mode; certain pins take on JTAG functionality R: 20 kΩ to GND - RESERVED, TI test mode F: Float - SMBus Master Mode 1: 1 kΩ to VDD - SMBus Slave Mode |

| SDA | G11 | I/O, 3.3V LVCMOS, Open Drain | None | SMBus data input / open drain output. External 2-kΩ to 5-kΩ pull-up resistor is required as per SMBus interface standard. This pin is 3.3V-tolerant. |

| SDC | H11 | I/O, 3.3V LVCMOS, Open Drain | None | SMBus clock input / open drain clock output. External 2-kΩ to 5-kΩ pull-up resistor is required as per SMBus interface standard. This pin is 3.3V-tolerant. |

| SMBus MASTER MODE PINS | ||||

| ALL_DONE_N | E1 | Output, LVCMOS | None | Indicates the completion of a valid EEPROM register load operation when in SMBus Master Mode (EN_SMB=Float):

High = External EEPROM load failed or incomplete Low = External EEPROM load successful and complete When in SMBus slave mode (EN_SMB=1), this output reflects the status of the READ_EN_N input. |

| READ_EN_N | E11 | Input, 3.3V LVCMOS | Weak pull-up | SMBus Master Mode (EN_SMB=Float): When asserted low, initiates the SMBus master mode EEPROM read function. Once EEPROM read is complete (indicated by assertion of ALL_DONE_N low), this pin can be held low for normal device operation.

SMBus Slave Mode (EN_SMB=1): When asserted low, this causes the device to be held in reset (SMBus state machine reset and register reset). This pin should be pulled high or left floating for normal operation in SMBus Slave Mode. This pin is 3.3V-tolerant. |

| MISCELLANEOUS PINS | ||||

| INT_N | H1 | Output, LVCMOS, Open Drain | None | Open-drain 3.3-V tolerant active-low interrupt output. This pin is pulled low when an interrupt occurs. The events which trigger an interrupt are programmable through SMBus registers. INT_N can be connected in a wired-OR fashion with other device's interrupt pin. A single pull-up resistor in the 2-kΩ to 5-kΩ range is adequate for the entire INT_N net. |

| TEST0/JTAG_TCK | D10 | Input, LVCMOS | No pull-up in JTAG mode. Weak pull-up in functional mode. | Reserved TI test pins. During normal (non-test-mode) operation, these pins are configured as inputs and therefore they are not affected by the presence of a signal. These pins may be left floating, tied to GND, or connected to a 2.5-V (max) output.

In JTAG mode (EN_SMB = 1 kΩ to GND), TEST0 is JTAG Test Clock (TCK) and TEST1 is JTAG Test Mode Select (TMS). |

| TEST1/JTAG_TMS | D2 | Input, LVCMOS | Weak pull-up | |

| TEST2 | E10 | Input, LVCMOS | Weak pull-up | Reserved TI test pins. During normal (non-test-mode) operation, these pins are configured as inputs and therefore they are not affected by the presence of a signal. These pins may be left floating, tied to GND, or connected to a 2.5-V (max) output. |

| TEST3 | E2 | Input, LVCMOS | Weak pull-up | |

| TEST4 | H10 | Input, LVCMOS | Weak pull-up | |

| TEST5 | H2 | Input, LVCMOS | Weak pull-up | |

| POWER | ||||

| GND | A3, A6, A9, B1, B2, B3, B4, B5, B6, B7, B8, B9, B10, B11, C1, C6, C11, D6, E3, E5, E7, E9, F3, F4, F5, F6, F7, F8, F9, G2, G3, G5, G7, G9, G10, H6, J1, J6, J11, K1, K2, K3, K4, K5, K6, K7, K8, K9, K10, K11, L3, L6, L9 | Power | None | Ground reference. The GND pins on this device should be connected through a low-resistance path to the board GND plane. |

| VDD | C3, C9, D3, D4, D5, D7, D8, D9, H3, H4, H5, H7, H8, H9, J3, J9 | Power | None | Power supply, VDD = 2.5 V ±5%. TI recommends connecting at least six de-coupling capacitors between the DS250DF410’s VDD plane and GND as close to the DS250DF410 as possible. For example, four 0.1-μF capacitors and two 1-μF capacitors directly beneath the device or as close to the VDD pins as possible. The VDD pins on this device should be connected through a low-resistance path to the board VDD plane. |

(1) High-speed pins do not have short-circuit protection. High-speed pins should be AC-coupled.