SLLSF22H April 2018 – June 2024 ISO1410 , ISO1412 , ISO1430 , ISO1432 , ISO1450 , ISO1452

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Description Continued

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

-

7 Specifications

- 7.1 Absolute Maximum Ratings

- 7.2 ESD Ratings

- 7.3 Recommended Operating Conditions

- 7.4 Thermal Information

- 7.5 Power Ratings

- 7.6 Insulation Specifications

- 7.7 Safety-Related Certifications

- 7.8 Safety Limiting Values

- 7.9 Electrical Characteristics: Driver

- 7.10 Electrical Characteristics: Receiver

- 7.11 Supply Current Characteristics: Side 1 (ICC1)

- 7.12 Supply Current Characteristics: Side 2 (ICC2)

- 7.13 Switching Characteristics: Driver

- 7.14 Switching Characteristics: Receiver

- 7.15 Insulation Characteristics Curves

- 7.16 Typical Characteristics

- 8 Parameter Measurement Information

- 9 Detailed Description

- 10Application and Implementation

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Revision History

- 15Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- DW|16

Thermal pad, mechanical data (Package|Pins)

- DW|16

Orderable Information

10.2.3.1 Insulation Lifetime

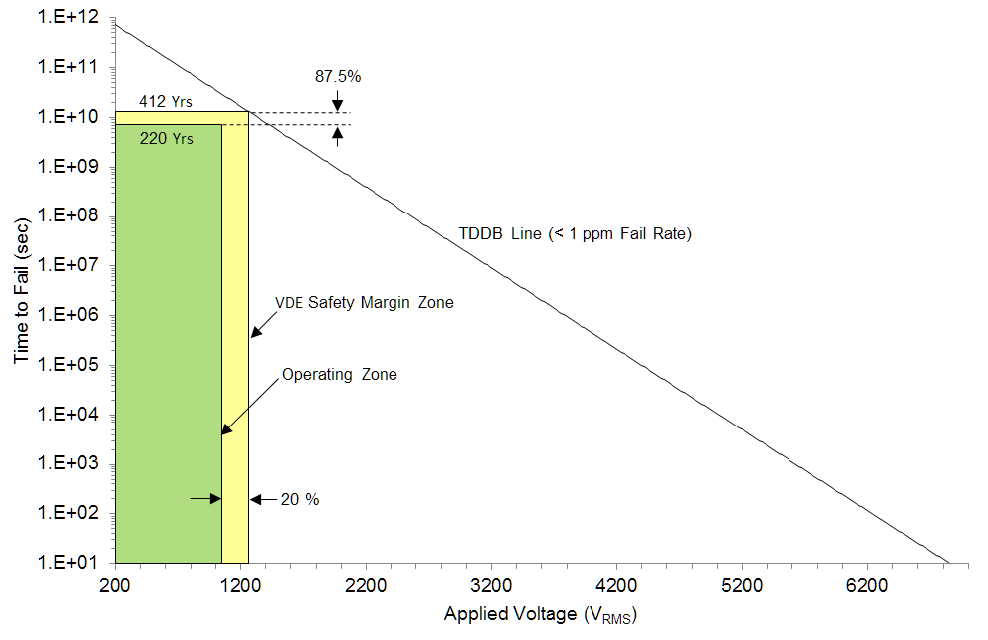

Insulation lifetime projection data is collected by using industry-standard Time Dependent Dielectric Breakdown (TDDB) test method. In this test, all pins on each side of the barrier are tied together creating a two-terminal device and high voltage applied between the two sides; See Figure 10-6 for TDDB test setup. The insulation breakdown data is collected at various high voltages switching at 60 Hz over temperature. For reinforced insulation, VDE standard requires the use of TDDB projection line with failure rate of less than 1 part per million (ppm). Even though the expected minimum insulation lifetime is 20 years at the specified working isolation voltage, VDE reinforced certification requires additional safety margin of 20% for working voltage and 87.5% for lifetime which translates into minimum required insulation lifetime of 37.5 years at a working voltage that's 20% higher than the specified value.

Figure 10-7 shows the intrinsic capability of the isolation barrier to withstand high voltage stress over its lifetime. Based on the TDDB data, the intrinsic capability of the insulation is 1060 VRMS with a lifetime of 220 years. Other factors, such as package size, pollution degree, material group, etc. can further limit the working voltage of the component. The working voltage of DW-16 is specified up to 1060 VRMS . At the lower working voltages, the corresponding insulation lifetime is much longer than 220 years.

Figure 10-6 Test Setup for Insulation Lifetime Measurement

Figure 10-6 Test Setup for Insulation Lifetime Measurement

| Working Isolation Voltage = 1060 VRMS | Projected Insulation Lifetime = 220 Years |

| TA up to 150°C | Applied Voltage Frequency = 60 Hz |