SNVS117E April 1998 – June 2019 LM2588

PRODUCTION DATA.

- 1 Features

- 2 Typical Applications

- 3 Description

- 4 Revision History

- 5 Pin Configurations

-

6 Specifications

- 6.1 Absolute Maximum Ratings

- 6.2 ESD Ratings

- 6.3 Recommended Operating Ratings

- 6.4 Electrical Characteristics: 3.3 V

- 6.5 Electrical Characteristics: 5 V

- 6.6 Electrical Characteristics: 12 V

- 6.7 Electrical Characteristics: Adjustable

- 6.8 Electrical Characteristics: All Output Voltage Versions

- 6.9 Typical Characteristics

- 7 Detailed Description

- 8 Application and Implementation

- 9 Layout

- 10Device and Documentation Support

- 11Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

Thermal pad, mechanical data (Package|Pins)

- KTW|7

Orderable Information

8.2.1.2.3 Switch Voltage Limits

In a flyback regulator, the maximum steady-state voltage appearing at the switch, when it is off, is set by the transformer turns ratio, N, the output voltage, VOUT, and the maximum input voltage, VIN (maximum):

where

- VF is the forward biased voltage of the output diode, and is typically 0.5 V for Schottky diodes and 0.8V for ultra-fast recovery diodes

In certain circuits, there exists a voltage spike, VLL, superimposed on top of the steady-state voltage (see Figure 18, waveform A). Usually, this voltage spike is caused by the transformer leakage inductance and/or the output rectifier recovery time. To “clamp” the voltage at the switch from exceeding its maximum value, a transient suppressor in series with a diode is inserted across the transformer primary (as shown in the circuit in Figure 16 and other flyback regulator circuits throughout the datasheet). The schematic in Figure 24 shows another method of clamping the switch voltage. A single voltage transient suppressor (the SA51A) is inserted at the switch pin. This method clamps the total voltage across the switch, not just the voltage across the primary.

If poor circuit layout techniques are used (see the section), negative voltage transients may appear on the Switch pin (pin 5). Applying a negative voltage (with respect to the IC's ground) to any monolithic IC pin causes erratic and unpredictable operation of that IC. This holds true for the LM2588 IC as well. When used in a flyback regulator, the voltage at the Switch pin (pin 5) can go negative when the switch turns on. The “ringing” voltage at the switch pin is caused by the output diode capacitance and the transformer leakage inductance forming a resonant circuit at the secondary(ies). The resonant circuit generates the “ringing” voltage, which gets reflected back through the transformer to the switch pin. There are two common methods to avoid this problem. One is to add an RC snubber around the output rectifier(s), as in Figure 24. The values of the resistor and the capacitor must be chosen so that the voltage at the Switch pin does not drop below −0.4 V. The resistor may range in value between 10Ω and 1 kΩ, and the capacitor will vary from 0.001 μF to 0.1 μF. Adding a snubber will (slightly) reduce the efficiency of the overall circuit.

The other method to reduce or eliminate the “ringing” is to insert a Schottky diode clamp between pins 5 and 4 (ground), also shown in Figure 24. This prevents the voltage at pin 5 from dropping below −0.4 V. The reverse voltage rating of the diode must be greater than the switch off voltage.

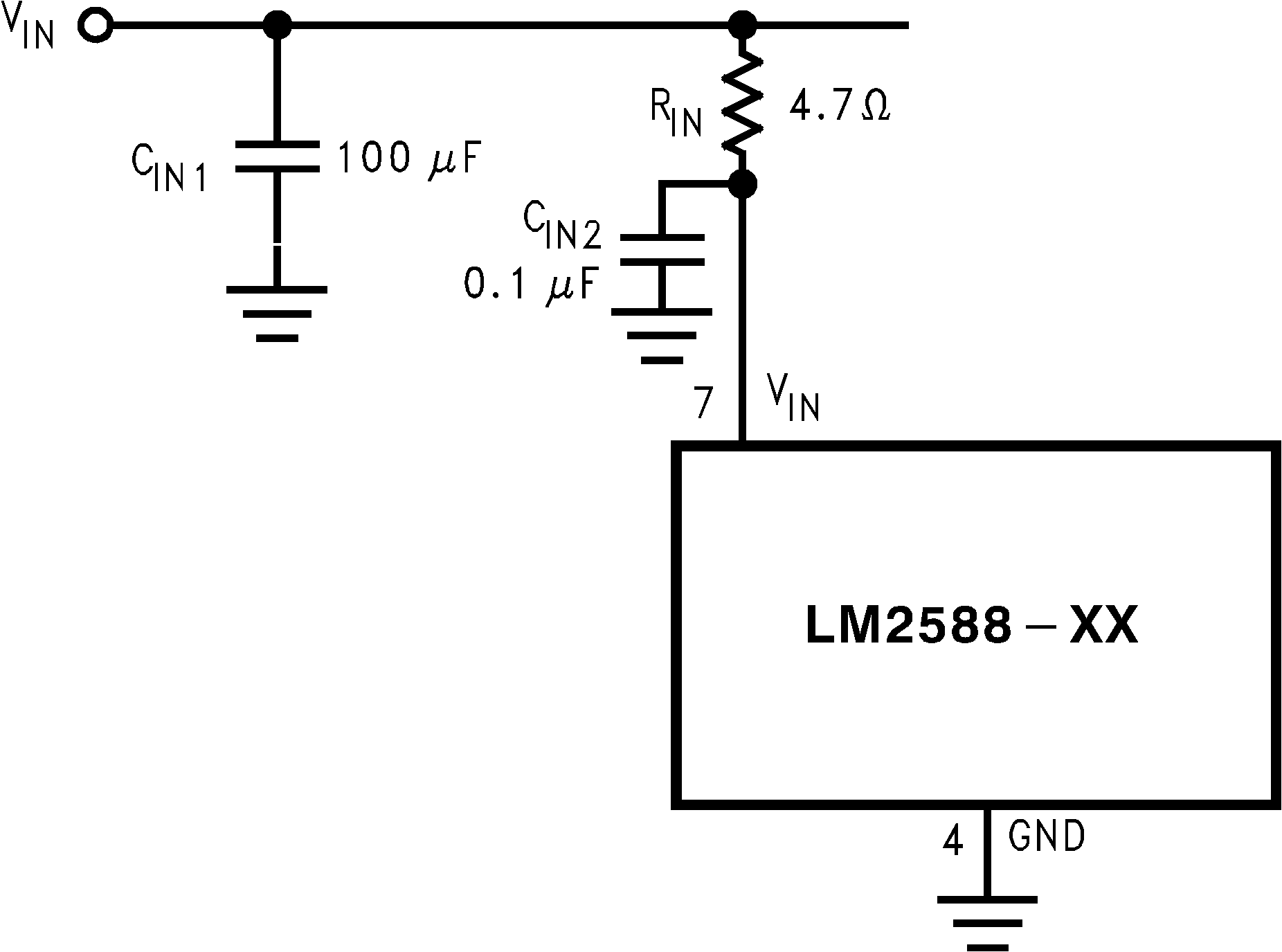

Figure 49. Input Line Filter

Figure 49. Input Line Filter