SNVS217G May 2004 – September 2015 LM2731

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

-

8 Application and Implementation

- 8.1 Application Information

- 8.2

Typical Application

- 8.2.1 Design Requirements

- 8.2.2

Detailed Design Procedure

- 8.2.2.1 Selecting the External Capacitors

- 8.2.2.2 Selecting the Output Capacitor

- 8.2.2.3 Selecting the Input Capacitor

- 8.2.2.4 Feedforward Compensation

- 8.2.2.5 Selecting Diodes

- 8.2.2.6 Setting the Output Voltage

- 8.2.2.7 Switching Frequency

- 8.2.2.8 Duty Cycle

- 8.2.2.9 Inductance Value

- 8.2.2.10 Maximum Switch Current

- 8.2.2.11 Calculating Load Current

- 8.2.2.12 Design Parameters VSW and ISW

- 8.2.2.13 Inductor Suppliers

- 8.2.3 Application Curves

- 8.3 System Examples

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- DBV|5

Thermal pad, mechanical data (Package|Pins)

Orderable Information

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

The device will operate with input voltage range from 2.7 V to 14 V and provide a regulated output voltage. This device is optimized for high-efficiency operation with minimum number of external components. For component selection, see Detailed Design Procedure.

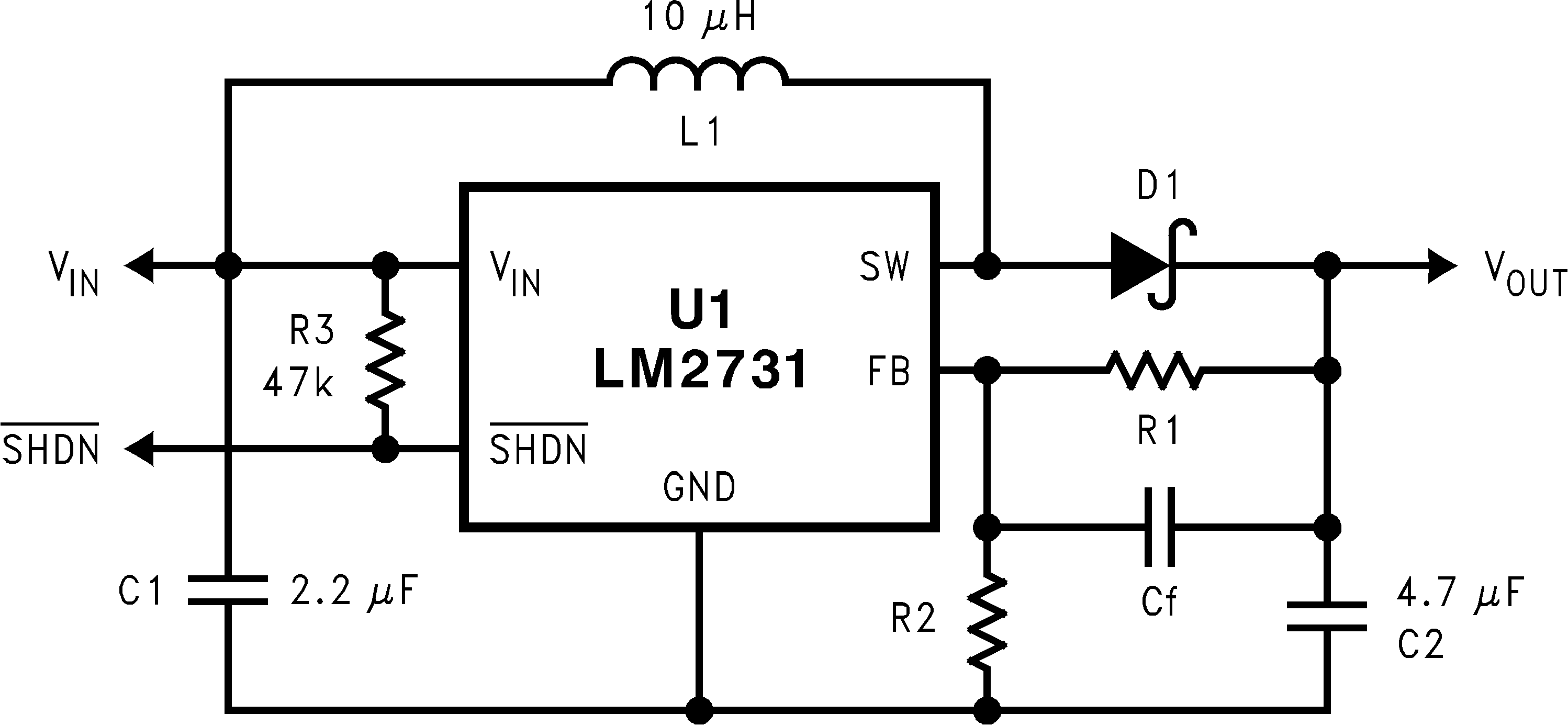

8.2 Typical Application

Figure 25. Efficiency vs Load Current

Figure 25. Efficiency vs Load Current

8.2.1 Design Requirements

The device must be able to operate at any voltage within the recommended operating range. The load current must be defined in order to properly size the inductor, input, and output capacitors. The inductor must be able to handle full expected load current as well as the peak current generated during load transients and start-up. Inrush current at start-up will depend on the output capacitor selection. More details are provided in Detailed Design Procedure.

The device has a shutdown pin which is used to disable the device. This pin is active-LOW and care must be taken that the voltage on this pin does not exceed VIN + 0.3 V. This pin must also not be left floating.

8.2.2 Detailed Design Procedure

8.2.2.1 Selecting the External Capacitors

The best capacitors for use with the LM2731 are multi-layer ceramic capacitors. These capacitors have the lowest ESR (equivalent series resistance) and highest resonance frequency which makes them optimum for use with high-frequency switching converters.

When selecting a ceramic capacitor, only X5R and X7R dielectric types should be used. Other types such as Z5U and Y5F have such severe loss of capacitance due to effects of temperature variation and applied voltage, they may provide as little as 20% of rated capacitance in many typical applications. Always consult capacitor manufacturer’s data curves before selecting a capacitor. High-quality ceramic capacitors can be obtained from Taiyo-Yuden, AVX, and Murata.

8.2.2.2 Selecting the Output Capacitor

A single ceramic capacitor of value 4.7 µF to 10 µF will provide sufficient output capacitance for most applications. If larger amounts of capacitance are desired for improved line support and transient response, tantalum capacitors can be used. Aluminum electrolytics with ultra low ESR such as Sanyo Oscon can be used, but are usually prohibitively expensive. Typical AI electrolytic capacitors are not suitable for switching frequencies above 500 kHz due to significant ringing and temperature rise due to self-heating from ripple current. An output capacitor with excessive ESR can also reduce phase margin and cause instability.

In general, if electrolytics are used, TI recommends that they be paralleled with ceramic capacitors to reduce ringing, switching losses, and output voltage ripple.

8.2.2.3 Selecting the Input Capacitor

An input capacitor is required to serve as an energy reservoir for the current which must flow into the coil each time the switch turns ON. This capacitor must have extremely low ESR, so ceramic is the best choice. TI recommends a nominal value of 2.2 µF, but larger values can be used. Since this capacitor reduces the amount of voltage ripple seen at the input pin, it also reduces the amount of EMI passed back along that line to other circuitry.

8.2.2.4 Feedforward Compensation

Although internally compensated, the feedforward capacitor Cf is required for stability (see Figure 26). Adding this capacitor puts a zero in the loop response of the converter. The recommended frequency for the zero fz should be approximately 6 kHz. Cf can be calculated using the formula:

8.2.2.5 Selecting Diodes

The external diode used in the typical application should be a Schottky diode. TI recommends a 20-V diode such as the MBR0520.

The MBR05XX series of diodes are designed to handle a maximum average current of 0.5 A. For applications exceeding 0.5-A average but less than 1 A, a Microsemi UPS5817 can be used.

8.2.2.6 Setting the Output Voltage

The output voltage is set using the external resistors R1 and R2 (see Figure 26). A minimum value of 13.3 kΩ is recommended for R2 to establish a divider current of approximately 92 µA. R1 is calculated using the formula:

8.2.2.7 Switching Frequency

The LM2731 is provided with two switching frequencies: the “X” version is typically 1.6 MHz, while the “Y” version is typically 600 kHz. The best frequency for a specific application must be determined based on the trade-offs involved:

Higher switching frequency means the inductors and capacitors can be made smaller and cheaper for a given output voltage and current. The down side is that efficiency is slightly lower because the fixed switching losses occur more frequently and become a larger percentage of total power loss. EMI is typically worse at higher switching frequencies because more EMI energy will be seen in the higher frequency spectrum where most circuits are more sensitive to such interference.

Figure 26. Basic Application Circuit

Figure 26. Basic Application Circuit

8.2.2.8 Duty Cycle

The maximum duty cycle of the switching regulator determines the maximum boost ratio of output-to-input voltage that the converter can attain in continuous mode of operation. The duty cycle for a given boost application is defined as:

This applies for continuous mode operation.

8.2.2.9 Inductance Value

The first question that is usually asked is: “How small can I make the inductor?” (because they are the largest sized component and usually the most costly). The answer is not simple and involves trade-offs in performance. Larger inductors mean less inductor ripple current, which typically means less output voltage ripple (for a given size of output capacitor). Larger inductors also mean more load power can be delivered because the energy stored during each switching cycle is:

Where “lp” is the peak inductor current. An important point to observe is that the LM2731 will limit its switch current based on peak current. This means that since lp(max) is fixed, increasing L will increase the maximum amount of power available to the load. Conversely, using too little inductance may limit the amount of load current which can be drawn from the output.

Best performance is usually obtained when the converter is operated in “continuous” mode at the load current range of interest, typically giving better load regulation and less output ripple. Continuous operation is defined as not allowing the inductor current to drop to zero during the cycle. All boost converters shift over to discontinuous operation as the output load is reduced far enough, but a larger inductor stays “continuous” over a wider load current range.

To better understand these trade-offs, a typical application circuit (5-V to 12-V boost with a 10-µH inductor) will be analyzed. We will assume:

Because the frequency is 1.6 MHz (nominal), the period is approximately 0.625 µs. The duty cycle will be 62.5%, which means the ON-time of the switch is 0.390 µs. When the switch is ON, the voltage across the inductor is approximately 4.5 V.

Using the equation:

The di/dt rate of the inductor can then be calculated, which is found to be 0.45 A/µs during the ON time. Using these facts, what the inductor current will look like during operation can be shown:

Figure 27. 10 µH Inductor Current, 5 V–12 V Boost (LM2731X)

Figure 27. 10 µH Inductor Current, 5 V–12 V Boost (LM2731X)

During the 0.390-µs ON-time, the inductor current ramps up 0.176 A and ramps down an equal amount during the OFF-time. This is defined as the inductor “ripple current”. If the load current drops to about 33 mA, the inductor current will begin touching the zero axis which means it will be in discontinuous mode. A similar analysis can be performed on any boost converter, to make sure the ripple current is reasonable and continuous operation will be maintained at the typical load current values.

8.2.2.10 Maximum Switch Current

The maximum FET switch current available before the current limiter cuts in is dependent on duty cycle of the application. This is illustrated in the graphs below which show typical values of switch current for both the "X" and "Y" versions as a function of effective (actual) duty cycle:

Figure 28. Switch Current Limit vs Duty Cycle - X Option

Figure 28. Switch Current Limit vs Duty Cycle - X Option

8.2.2.11 Calculating Load Current

As shown in the figure which depicts inductor current, the load current is related to the average inductor current by the relation:

Where "DC" is the duty cycle of the application. The switch current can be found by:

Inductor ripple current is dependent on inductance, duty cycle, input voltage and frequency:

Combining all terms, an expression can be developed which allows the maximum available load current to be calculated:

The equation shown to calculate maximum load current takes into account the losses in the inductor or turn-OFF switching losses of the FET and diode. For actual load current in typical applications, we took bench data for various input and output voltages for both the "X" and "Y" versions of the LM2731 and displayed the maximum load current available for a typical device in graph form:

Figure 31. Maximum Load Current (Typical) vs VIN - Y Option

Figure 31. Maximum Load Current (Typical) vs VIN - Y Option

8.2.2.12 Design Parameters VSW and ISW

The value of the FET "ON" voltage (referred to as VSW in the equations) is dependent on load current. A good approximation can be obtained by multiplying the "ON-Resistance" of the FET times the average inductor current.

FET on resistance increases at VIN values less than 5 V, since the internal N-FET has less gate voltage in this input voltage range (see Typical Characteristics curves). Above VIN = 5V, the FET gate voltage is internally clamped to 5V.

The maximum peak switch current the device can deliver is dependent on duty cycle. For higher duty cycles, see Typical Characteristics.

8.2.2.13 Inductor Suppliers

Recommended suppliers of inductors for this product include, but are not limited to Sumida, Coilcraft, Panasonic, TDK, and Murata. When selecting an inductor, make certain that the continuous current rating is high enough to avoid saturation at peak currents. A suitable core type must be used to minimize core (switching) losses, and wire power losses must be considered when selecting the current rating.

8.2.3 Application Curves

| VIN = 3.3 V | VOUT = 5 V | |

| VIN = 3.3 V | VOUT = 12 V |

8.3 System Examples

Figure 35. Efficiency vs Load Current

Figure 35. Efficiency vs Load Current

Figure 37. Efficiency vs Load Current

Figure 37. Efficiency vs Load Current

Figure 39. Efficiency vs Load Current

Figure 39. Efficiency vs Load Current

Figure 40. White LED Flash Application

Figure 40. White LED Flash Application