SNVS731B September 2011 – June 2019 LMR12010

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Layout

- 10Device and Documentation Support

- 11Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- DDC|6

Thermal pad, mechanical data (Package|Pins)

Orderable Information

9.2 Calculating The LMR12010 Junction Temperature

Thermal Definitions:

- TJ = Chip junction temperature

- TA = Ambient temperature

- RθJC = Thermal resistance from chip junction to device case

- RθJA = Thermal resistance from chip junction to ambient air

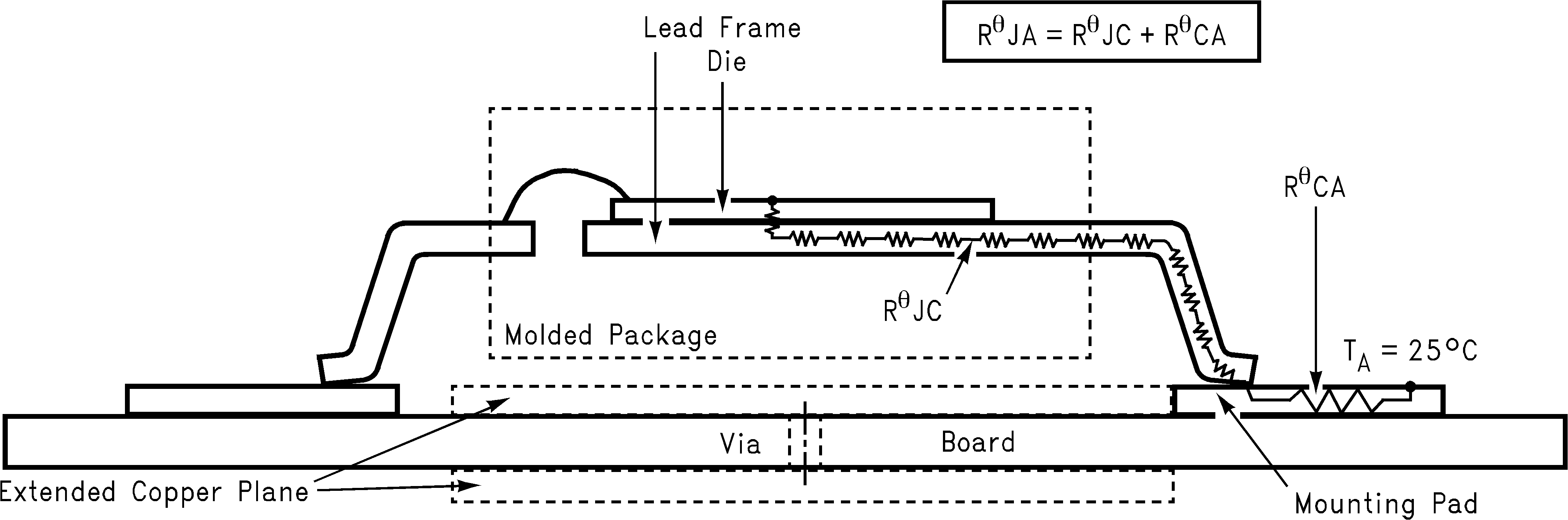

Figure 25. Cross-Sectional View of Integrated Circuit Mounted on a Printed Circuit Board.

Figure 25. Cross-Sectional View of Integrated Circuit Mounted on a Printed Circuit Board. Heat in the LMR12010 due to internal power dissipation is removed through conduction and/or convection.

Conduction: Heat transfer occurs through cross sectional areas of material. Depending on the material, the transfer of heat can be considered to have poor to good thermal conductivity properties (insulator vs conductor).

Heat transfer goes as:

silicon→package→lead frame→PCB.

Convection: Heat transfer is by means of airflow. This could be from a fan or natural convection. Natural convection occurs when air currents rise from the hot device to cooler air.

Thermal impedance is defined as:

Thermal impedance from the silicon junction to the ambient air is defined as:

This impedance can vary depending on the thermal properties of the PCB. This includes PCB size, weight of copper used to route traces and ground plane, and number of layers within the PCB. The type and number of thermal vias can also make a large difference in the thermal impedance. Thermal vias are necessary in most applications. They conduct heat from the surface of the PCB to the ground plane. Place two to four thermal vias close to the ground pin of the device.

The datasheet specifies two different RθJA numbers for the 6-pin SOT-23-THIN package. The two numbers show the difference in thermal impedance for a four-layer board with 2-oz. copper traces, vs. a four-layer board with 1oz. copper. RθJA equals 120°C/W for 2-oz. copper traces and GND plane, and 235°C/W for 1oz. copper traces and GND plane.

Method 1:

To accurately measure the silicon temperature for a given application, two methods can be used. The first method requires the user to know the thermal impedance of the silicon junction to case. (RθJC) is approximately 80°C/W for the 6-pin SOT-23-THIN package. Knowing the internal dissipation from the efficiency calculation given previously, and the case temperature, which can be empirically measured on the bench we have:

Therefore:

Table 3. Design Example 2

| VIN | 5 V | POUT | 2.5 W |

| VOUT | 2.5 V | PDIODE | 151 mW |

| IOUT | 1 A | PIND | 75 mW |

| VD | 0.35 V | PSWF | 53 mW |

| Freq | 3 MHz | PSWR | 53 mW |

| IQ | 1.5 mA | PCOND | 187 mW |

| TRISE | 8 ns | PQ | 7.5 mW |

| TFALL | 8 ns | PBOOST | 21 mW |

| RDSON | 330 mΩ | PLOSS | 548 mW |

| INDDCR | 75 mΩ | ||

| D | 0.568 |

The second method can give a very accurate silicon junction temperature. The first step is to determine RθJA of the application. The LMR12010 has over-temperature protection circuitry. When the silicon temperature reaches 165°C, the device stops switching. The protection circuitry has a hysteresis of 15°C. Once the silicon temperature has decreased to approximately 150°C, the device will start to switch again. Knowing this, the RθJA for any PCB can be characterized during the early stages of the design by raising the ambient temperature in the given application until the circuit enters thermal shutdown. If the SW pin is monitored, it will be obvious when the internal NFET stops switching indicating a junction temperature of 165°C. Knowing the internal power dissipation from the above methods, the junction temperature and the ambient temperature, RθJA can be determined.

Once this is determined, the maximum ambient temperature allowed for a desired junction temperature can be found.

Table 4. Design Example 3

| Package | SOT23-6 | ||

| VIN | 12 V | POUT | 2.475 W |

| VOUT | 3.3 V | PDIODE | 523 mW |

| IOUT | 750 mA | PIND | 56.25 mW |

| VD | 0.35 V | PSWF | 108 mW |

| Freq | 3 MHz | PSWR | 108 mW |

| IQ | 1.5 mA | PCOND | 68.2 mW |

| IBOOST | 4 mA | PQ | 18 mW |

| VBOOST | 5 V | PBOOST | 20 mW |

| TRISE | 8 ns | PLOSS | 902 mW |

| TFALL | 8 ns | ||

| RDSON | 400 mΩ | ||

| INDDCR | 75 mΩ | ||

| D | 30.3% |

Using a standard Texas Instruments 6-pin SOT-23-THIN demonstration board to determine the RθJA of the board. The four-layer PCB is constructed using FR4 with 1/2-oz copper traces. The copper ground plane is on the bottom layer. The ground plane is accessed by two vias. The board measures 2.5 cm × 3 cm. It was placed in an oven with no forced airflow.

The ambient temperature was raised to 94°C, and at that temperature, the device went into thermal shutdown.

If the junction temperature was to be kept below 125°C, then the ambient temperature cannot go above 54.2°C.