SNVS686K March 2011 – May 2024 LMZ22005

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Pin Configuration and Functions

- 5 Specifications

- 6 Detailed Description

- 7 Application and Implementation

- 8 Power Supply Recommendations

- 9 Layout

- 10Device and Documentation Support

- 11Revision History

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- NDW|7

Thermal pad, mechanical data (Package|Pins)

Orderable Information

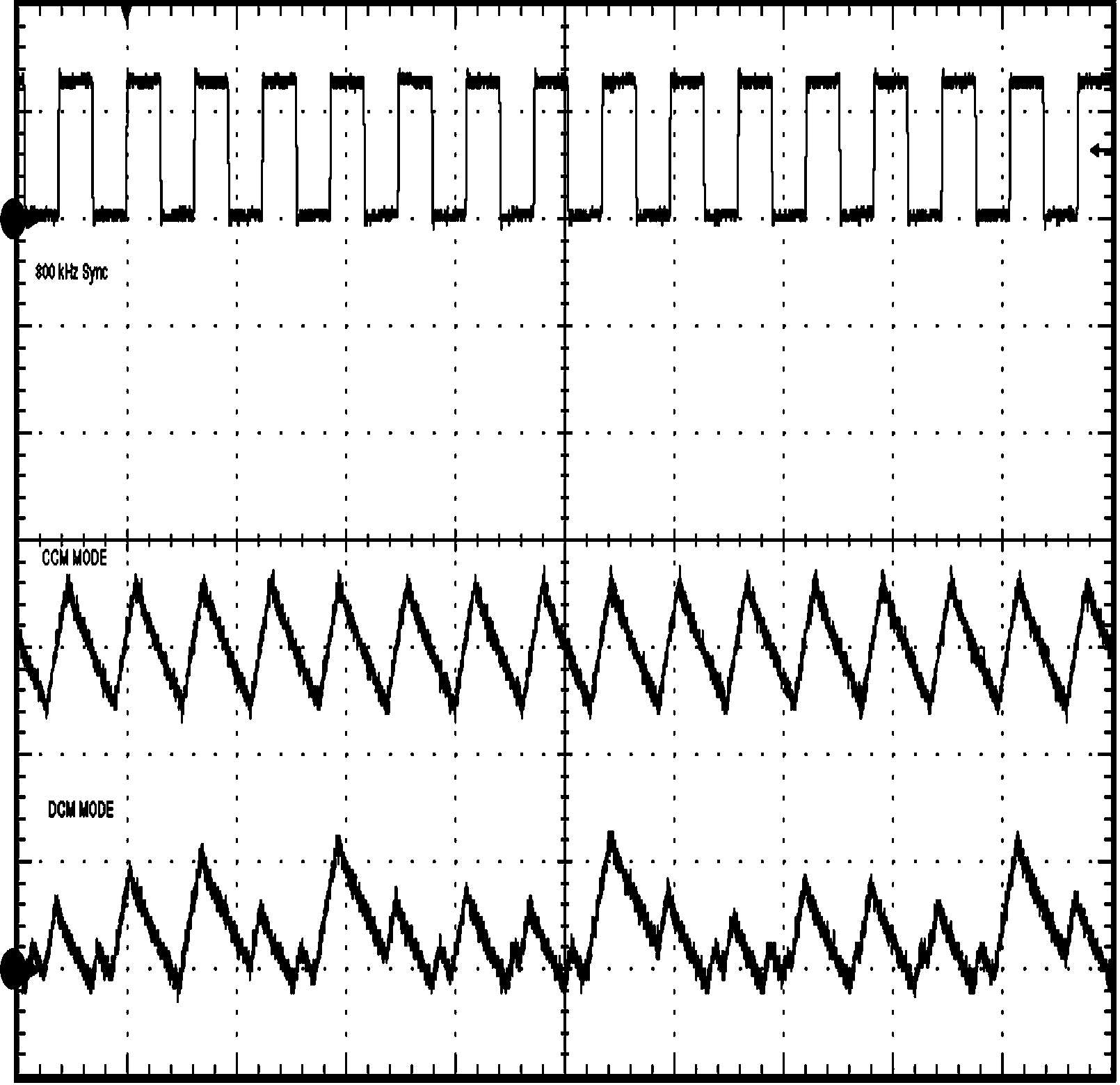

6.4.1 Discontinuous And Continuous Conduction Modes

At light load the regulator will operate in discontinuous conduction mode (DCM). With load currents above the critical conduction point, it will operate in continuous conduction mode (CCM). In CCM, current flows through the inductor through the entire switching cycle and never falls to zero during the OFF-time. When operating in DCM, inductor current is maintained to an average value equaling IOUT. Inductor current exhibits normal behavior for the emulated current mode control method used. Output voltage ripple typically increases during this mode of operation.

Figure 6-2 is a comparison pair of waveforms of the showing both CCM (upper) and DCM operating modes.