-

LPV801/LPV802 320 nA Nanopower Operational Amplifiers

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

- IMPORTANT NOTICE

Package Options

Mechanical Data (Package|Pins)

- DGK|8

Thermal pad, mechanical data (Package|Pins)

Orderable Information

LPV801/LPV802 320 nA Nanopower Operational Amplifiers

1 Features

- Nanopower Supply Current: 320 nA/channel

- Offset Voltage: 3.5 mV (max)

- TcVos: 1 µV/°C

- Unity Gain-Bandwidth: 8 kHz

- Wide Supply Range: 1.6 V to 5.5 V

- Low Input Bias Current : 0.1 pA

- Unity-Gain Stable

- Rail-to-Rail Output

- No Output Reversals

- EMI Protection

- Temperature Range: –40°C to 125°C

- Industry Standard Packages:

- Single in 5-pin SOT-23

- Dual in 8-pin VSSOP

2 Applications

- CO and O2 Gas Detectors (TIDA-00854)

- PIR Motion Detectors (TIDA-00489)

- Ionization Smoke Alarms

- Thermostats

- IoT Remote Sensors

- Active RFID Readers and Tags

- Portable Medical Equipment

3 Description

The LPV801 (single) and LPV802 (dual) comprise a family of ultra-low-power operational amplifiers for sensing applications in battery powered wireless and low power wired equipment. With 8kHz of bandwidth from 320nA of quiescent current, the LPV80x amplifiers minimize power consumption in equipment such as CO detectors, smoke detectors and PIR motion detectors where operational battery-life is critical.

In addition to being ultra-low-power, the LPV80x amplifiers have CMOS input stages with typically femto-amp bias currents. The LPV80x amplifiers also feature a negative-rail sensing input stage and a rail-to-rail output stage that is capable of swinging within millivolts of the rails, maintaining the widest dynamic range possible. EMI protection is designed into the LPV80x in order to reduce system sensitivity to unwanted RF signals from mobile phones, WiFi, radio transmitters and tag readers.

Device Information(1)

| PART NUMBER | PACKAGE | BODY SIZE |

|---|---|---|

| LPV801 | SOT-23 (5) | 2.90 mm x 1.60 mm |

| LPV802 | VSSOP (8) | 3.00 mm × 3.00 mm |

LPV8xx Family of Nanopower Amplifiers

| PART NUMBER | CHANNELS | SUPPLY CURRENT (Typ/Ch) |

OFFSET VOLTAGE (Max) |

|---|---|---|---|

| LPV801 | 1 | 450 nA | 3.5 mV |

| LPV802 | 2 | 320 nA | 3.5 mV |

| LPV811 | 1 | 450 nA | 370 µV |

| LPV812 | 2 | 425 nA | 300 µV |

Nanopower Amplifier in Electrochemical Sensor

Nanopower Amplifier in PIR Motion Detector

4 Revision History

Changes from A Revision (August 2016) to B Revision

- Changed LPV811 Typ Offset Voltage and LPV812 Typ Supply Current in LPV8xx Family table Go

- Deleted LPV801 "Specs Prelim until Release" footnote Go

- Added seporate CMRR line for LPV801 Go

- Changed LPV801 Typical and Maximum Supply Current Go

Changes from * Revision (August 2016) to A Revision

- Changed Product Preview to Production DataGo

5 Pin Configuration and Functions

Pin Functions: LPV801 DBV

| PIN | I/O | DESCRIPTION | ||

|---|---|---|---|---|

| NAME | NUMBER | |||

| OUT | 1 | O | Output | |

| -IN | 4 | I | Inverting Input | |

| +IN | 3 | I | Non-Inverting Input | |

| V- | 2 | P | Negative (lowest) power supply | |

| V+ | 5 | P | Positive (highest) power supply | |

Pin Functions: LPV802 DGK

| PIN | I/O | DESCRIPTION | ||

|---|---|---|---|---|

| NAME | NUMBER | |||

| OUT A | 1 | O | Channel A Output | |

| -IN A | 2 | I | Channel A Inverting Input | |

| +IN A | 3 | I | Channel A Non-Inverting Input | |

| V- | 4 | P | Negative (lowest) power supply | |

| +IN B | 5 | I | Channel B Non-Inverting Input | |

| -IN B | 6 | I | Channel B Inverting Input | |

| OUT B | 7 | O | Channel B Output | |

| V+ | 8 | P | Positive (highest) power supply | |

6 Specifications

6.1 Absolute Maximum Ratings

Over operating free-air temperature range (unless otherwise noted) (1)| MIN | MAX | UNIT | |||

|---|---|---|---|---|---|

| Supply voltage, Vs = (V+) - (V-) | –0.3 | 6 | V | ||

| Input pins | Voltage (2) (3) | Common mode | (V-) - 0.3 | (V+) + 0.3 | V |

| Differential | (V-) - 0.3 | (V+) + 0.3 | V | ||

| Input pins | Current | -10 | 10 | mA | |

| Output short current (4) | Continuous | Continuous | |||

| Operating temperature | –40 | 125 | °C | ||

| Storage temperature, Tstg | –65 | 150 | °C | ||

| Junction temperature | 150 | °C | |||

6.2 ESD Ratings

| VALUE | UNIT | |||

|---|---|---|---|---|

| V(ESD) | Electrostatic discharge | Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001(1) | ±1000 | V |

| Charged-device model (CDM), per JEDEC specification JESD22-C101(2) | ±250 | |||

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)| MIN | NOM | MAX | UNIT | ||

|---|---|---|---|---|---|

| Supply voltage (V+ – V–) | 1.6 | 5.5 | V | ||

| Specified temperature | -40 | 125 | °C | ||

6.4 Thermal Information

| THERMAL METRIC(1) | LPV801 DBV (SOT-23) 5 PINS |

LPV802 DGK (VSSOP) 8 PINS |

UNIT | |

|---|---|---|---|---|

| θJA | Junction-to-ambient thermal resistance | 177.4 | 184.2 | ºC/W |

| θJCtop | Junction-to-case (top) thermal resistance | 133.9 | 75.3 | |

| θJB | Junction-to-board thermal resistance | 36.3 | 105.5 | |

| ψJT | Junction-to-top characterization parameter | 23.6 | 13.5 | |

| ψJB | Junction-to-board characterization parameter | 35.7 | 103.9 | |

6.5 Electrical Characteristics

TA = 25°C, VS = 1.8V to 5 V, VCM = VOUT = VS/2, and RL≥ 10 MΩ to VS / 2, unless otherwise noted.6.6 Typical Characteristics

at TA = 25°C, RL = 10MΩ to VS/2 ,CL = 20pF, VCM = VS / 2V unless otherwise specified.

| VCM = V- | LPV801 | RL=No Load |

| VS= 1.8V | RL= 10MΩ |

| VS= 5V | RL= 10MΩ |

| VS= 1.8V | TA = -40°C |

| VS= 1.8V | TA = 25°C |

| VS= 1.8V | TA = 125°C |

| VS= 1.8V | RL= No Load |

| VS= 3.3V | RL= No Load |

| VS= 5V | RL= No Load |

| TA = 25 | RL= 10MΩ | Vout = 200mVpp |

| VS= ±0.9V | CL= 20pF | AV = +1 |

| TA = 25 | RL= 10MΩ | Vout = 1Vpp |

| VS= ±0.9V | CL= 20pF | AV = +1 |

| TA = 25 | RL= 10MΩ | ΔVCM = 0.5Vpp |

| VS= 5V | CL= 20p | |

| VCM = Vs/2 | AV = +1 |

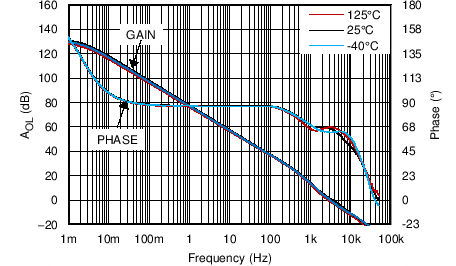

| TA = -40, 25, 125°C | RL= 10MΩ | VOUT = 200mVPP |

| VS= 5V | CL= 20pF | VCM = Vs/2 |

| TA = -40, 25, 125°C | RL= 1MΩ | VOUT = 200mVPP |

| VS= 5V | CL= 20pF | VCM = Vs/2 |

| TA = -40, 25, 125°C | RL= 100kΩ | VOUT = 200mVPP |

| VS= 5V | CL= 20pF | VCM = Vs/2 |

| TA = -40, 25, 125°C | RL= 10MΩ | VOUT = 200mVPP |

| VS= 1.8V | CL= 20pF | VCM = Vs/2 |

| TA = -40, 25, 125°C | RL= 1MΩ | VOUT = 200mVPP |

| VS= 1.8V | CL= 20pF | VCM = Vs/2 |

| TA = -40, 25, 125°C | RL= 100kΩ | VOUT = 200mVPP |

| VS= 1.8V | CL= 20pF | VCM = Vs/2 |

| VCM = V- | LPV802 | RL=No Load |

| VS= 3.3V | RL= 10MΩ |

| VS= 5V | TA = -40 to 125 | VCM = Vs/2 |

| VS= 5V | TA = -40°C |

| VS= 5V | TA = 25°C |

| VS= 5V | TA = 125°C |

| VS= 1.8V | RL= No Load |

| VS= 3.3V | RL= No Load |

| VS= 5V | RL= No Load |

| TA = 25 | RL= 10MΩ | Vout = 200mVpp |

| VS= ±2.5V | CL= 20pF | AV = +1 |

| TA = 25 | RL= 10MΩ | Vout = 2Vpp |

| VS= ±2.5V | CL= 20pF | AV = +1 |

| TA = 25 | RL= 10MΩ | ΔVS = 0.5Vpp |

| VS= 3.3V | CL= 20p | |

| VCM = Vs/2 | AV = +1 |

| TA = -40, 25, 125°C | RL= 10MΩ | VOUT = 200mVPP |

| VS= 3.3V | CL= 20pF | VCM = Vs/2 |

| TA = -40, 25, 125°C | RL= 1MΩ | VOUT = 200mVPP |

| VS= 3.3V | CL= 20pF | VCM = Vs/2 |

| TA = -40, 25, 125°C | RL= 100kΩ | VOUT = 200mVPP |

| VS= 3.3V | CL= 20pF | VCM = Vs/2 |

| TA = 25°C | VS= 5 V | RL= 10MΩ |

| TA = 25 | RL= 1MΩ | VCM = Vs/2 |

| VS= 5V | CL= 20pF | AV = +1 |

| TA = 25 | RL= 1MΩ | VCM = Vs/2 |

| VS= 3.3V | CL= 20pF | AV = +1 |