-

TPA311xD2-Q1 100-W and 50-W Class-D Stereo Automotive Amplifiers SLOS862B July 2015 – October 2016 TPA3116D2-Q1 , TPA3118D2-Q1

PRODUCTION DATA.

-

TPA311xD2-Q1 100-W and 50-W Class-D Stereo Automotive Amplifiers

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3

Feature Description

- 7.3.1 Gain Setting and Master and Slave

- 7.3.2 Input Impedance

- 7.3.3 Start-Up and Shutdown Operation

- 7.3.4 PLIMIT Operation

- 7.3.5 GVDD Supply

- 7.3.6 BSPx and BSNx Capacitors

- 7.3.7 Differential Inputs

- 7.3.8 Device Protection System

- 7.3.9 DC-Detect Protection

- 7.3.10 Short-Circuit Protection and Automatic Recovery Feature

- 7.3.11 Thermal Protection

- 7.3.12 TPA311xD2-Q1 Modulation Scheme

- 7.3.13 AM Avoidance EMI Reduction

- 7.4 Device Functional Mode

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

- IMPORTANT NOTICE

Package Options

Mechanical Data (Package|Pins)

- DAP|32

Thermal pad, mechanical data (Package|Pins)

- DAP|32

Orderable Information

TPA311xD2-Q1 100-W and 50-W Class-D Stereo Automotive Amplifiers

1 Features

- Supports Multiple Output Configurations

- 2 × 50 W Into a 4-Ω BTL Load at 21 V (TPA3116D2-Q1)

- 2 × 30 W Into an 8-Ω BTL Load at 24 V (TPA3118D2-Q1)

- Wide Voltage Range: 4.5 V to 26 V

- Efficient Class-D Operation

- >90% Power Efficiency Combined With Low Idle Loss Greatly Reduces Heat Sink Size

- Advanced Modulation Schemes

- Multiple Switching Frequencies

- AM Avoidance

- Master and Slave Synchronization

- Up to 1.2-MHz Switching Frequency

- Feedback Power-Stage Architecture With High PSRR Reduces PSU Requirements

- Programmable Power Limit

- Differential and Single-Ended Inputs

- Stereo BTL and Mono PBTL Modes

- Single Power Supply Reduces Component Count

- Integrated Self-Protection Circuits Including Overvoltage, Undervoltage, Overtemperature, DC-Detect, and Short Circuit With Error Reporting

- Designed for Automotive EMC Requirements

- Thermally Enhanced Packages

- DAD (32-pin HTSSOP Pad Up)

- DAP (32-pin HTSSOP Pad Down)

- –40°C to 125°C Ambient Temperature Range

- Qualified for Automotive Applications

- AEC-Q100 Qualified With the Following Results:

- Device Temperature Grade 1: –40°C to 125°C Ambient Operating Temperature Range

- Device HBM ESD Classification Level H2

- Device CDM ESD Classification Level C4B

2 Applications

- Automotive Audio

- Emergency Call

- Driver Notifications

3 Description

The TPA311xD2-Q1 devices are automotive stereo, efficient, digital-amplifier power stages for driving speakers up to 100 W into 2 Ω in mono. The TPA3118D2-Q1 can even drive 2 × 30 W into 8 Ω without a heat sink on a dual-layer PCB. If even higher power is needed, the TPA3116D2-Q1 drives 2 × 50 W into 4 Ω with a small heat sink attached to its top-side thermal pad.

The TPA311xD2-Q1 advanced oscillator and PLL circuit employ a multiple-switching-frequency option to avoid AM interference; this is achieved together with an option of either master or slave selection, making it possible to synchronize multiple devices.

The TPA311xD2-Q1 devices are fully protected against faults with short-circuit protection and thermal protection as well as overvoltage, undervoltage and dc protection. Faults are reported back to the processor to prevent devices from being damaged during overload conditions.

Device Information(1)

| DEVICE | PACKAGE | BODY SIZE (NOM) |

|---|---|---|

| TPA3116D2-Q1 | HTSSOP (32) | 11.00 mm × 6.20 mm |

| TPA3118D2-Q1 |

- For all available packages, see the orderable addendum at the end of the datasheet.

Simplified Application Circuit

4 Revision History

Changes from A Revision (August 2015) to B Revision

- Changed Table 3, column R to GND From: Short To: Open and column R to GVDD From: Open To: ShortGo

- Changed Figure 19 Go

Changes from * Revision (July 2015) to A Revision

- Added all information following the pin description diagramsGo

5 Pin Configuration and Functions

Pin Functions

| PIN | TYPE(1) | DESCRIPTION | |

|---|---|---|---|

| NAME | NO. | ||

| AM[2:0] | 13–15 | I | AM avoidance frequency selection |

| AVCC | 17 | P | Analog supply |

| BSNL | 20 | BST | Bootstrap for negative left channel output, connect to 220-nF X5R, or better ceramic cap to OUTPL |

| BSNR | 26 | BST | Bootstrap for negative right channel output, connect to 220-nF X5R, or better ceramic cap to OUTNR |

| BSPL | 24 | BST | Bootstrap for positive left channel output, connect to 220-nF X5R, or better ceramic cap to OUTNL |

| BSPR | 30 | BST | Bootstrap for positive right channel output, connect to 220-nF X5R or better ceramic cap to OUTPR |

| FAULT | 3 | DO | General fault reporting including overtemperature, dc detect, open drain. FAULT = High, normal operation FAULT = Low, fault condition |

| GAIN/SLV | 8 | I | Selects gain and selects between master and slave modes depending on pin voltage divider. |

| GND | 9, 22, 25, 28 | G | Ground |

| GVDD | 7 | PO | Internally generated gate voltage supply. Not to be used as a supply or connected to any component other than a 1-µF X7R ceramic decoupling capacitor and the PLIMIT and GAIN/SLV resistor dividers. |

| LINN | 11 | I | Negative audio input for left channel. Biased at 3 V. Connect to GND for PBTL mode. |

| LINP | 10 | I | Positive audio input for left channel. Biased at 3 V. Connect to GND for PBTL mode. |

| MODSEL | 1 | I | Mode selection logic input (LOW = BD mode, HIGH = 1 SPW mode). TTL logic levels with compliance to AVCC. |

| MUTE | 12 | I | Mute signal for fast disable or enable of outputs (HIGH = outputs Hi-Z, LOW = outputs enabled). TTL logic levels with compliance to AVCC. |

| OUTNL | 21 | PO | Negative left-channel output |

| OUTNR | 27 | PO | Negative right-channel output |

| OUTPL | 23 | PO | Positive left-channel output |

| OUTPR | 29 | PO | Positive right-channel output |

| PLIMIT | 6 | I | Power limit level adjust. Connect a resistor divider from GVDD to GND to set power limit. Connect directly to GVDD for no power limit. |

| PVCC | 18, 19, 31, 32 | P | Power supply |

| RINN | 5 | I | Negative audio input for right channel. Biased at 3 V. |

| RINP | 4 | I | Positive audio input for right channel. Biased at 3 V. |

| SD | 2 | I | Shutdown logic input for audio amp (LOW = outputs Hi-Z, HIGH = outputs enabled). TTL logic levels with compliance to AVCC. |

| SYNC | 16 | DIO | Clock input/output for synchronizing multiple class-D devices. Direction determined by GAIN/SLV pin. |

| Thermal pad | — | G | Connect to GND for best system performance. If not connected to GND, leave floating. |

6 Specifications

6.1 Absolute Maximum Ratings

over operating ambient temperature range (unless otherwise noted)(1)| MIN | MAX | UNIT | ||

|---|---|---|---|---|

| Supply voltage, VCC | PVCC, AVCC | –0.3 | 30 | V |

| Input voltage, VI | INPL, INNL, INPR, INNR | –0.3 | 6.3 | V |

| PLIMIT, GAIN/SLV, SYNC | –0.3 | GVDD + 0.3 | V | |

| AM0, AM1, AM2, MUTE, SD, MODSEL | –0.3 | PVCC + 0.3 | V | |

| Slew rate, maximum(2) | AM0, AM1, AM2, MUTE, SD, MODSEL | 10 | V/ms | |

| Operating ambient temperature, TA | –40 | 125 | °C | |

| Operating junction temperature range, TJ | –40 | 150 | °C | |

| Storage temperature range, Tstg | –40 | 125 | °C | |

6.2 ESD Ratings

| VALUE | UNIT | ||||

|---|---|---|---|---|---|

| V(ESD) | Electrostatic discharge | Human-body model (HBM), per AEC Q100-002(1) | ±2000 | V | |

| Charged-device model (CDM), per AEC Q100-011 | All pins | ±450 | |||

| Corner pins (1, 16, 17, and 32) | ±450 | ||||

6.3 Recommended Operating Conditions

over operating ambient temperature range (unless otherwise noted)| MIN | NOM | MAX | UNIT | ||||

|---|---|---|---|---|---|---|---|

| VCC | Supply voltage | PVCC, AVCC | 4.5 | 26 | V | ||

| VIH | High-level input voltage | AM0, AM1, AM2, MUTE, SD, SYNC, MODSEL | 2 | V | |||

| VIL | Low-level input voltage | AM0, AM1, AM2, MUTE, SD, SYNC, MODSEL | 0.8 | V | |||

| VOL | Low-level output voltage | FAULT, RPULLUP = 100 kΩ, V(PVCC) = 26 V | 0.8 | V | |||

| IIH | High-level input current | AM0, AM1, AM2, MUTE, SD, MODSEL (VI = 2 V, VCC = 18 V) | 50 | µA | |||

| RL | Minimum load impedance | Output filter: L = 10 µH, C = 680 nF, BTL | 3.2 | 4 | Ω | ||

| Output filter: L = 10 µH, C = 1 µF, PBTL | 1.6 | ||||||

| Lo | Output-filter inductance | Minimum output filter inductance under short-circuit condition | 1 | µH | |||

6.4 Thermal Information

| THERMAL METRIC(1) | TPA3116D2-Q1 | TPA3118D2-Q1 | UNIT | |

|---|---|---|---|---|

| DAD | DAP | |||

| 32 PINS | 32 PINS | |||

| RθJA | Junction-to-ambient thermal resistance | 44.7(2) | 32.4 | °C/W |

| RθJC(top) | Junction-to-case (top) thermal resistance | 1.2 | 17.2 | °C/W |

| RθJB | Junction-to-board thermal resistance | 21.5 | 17.3 | °C/W |

| ψJT | Junction-to-top characterization parameter | 1.2 | 0.4 | °C/W |

| ψJB | Junction-to-board characterization parameter | 21 | 17.2 | °C/W |

| RθJC(bot) | Junction-to-case (bottom) thermal resistance | N/A | 1 | °C/W |

6.5 DC Electrical Characteristics

TA = 25°C, AVCC = PVCC = 12 V to 24 V, RL = 4 Ω (unless otherwise noted)| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX | UNIT | ||

|---|---|---|---|---|---|---|---|

| | VOS | | Class-D output offset voltage (measured differentially) | VI = 0 V, gain = 36 dB | 1.5 | 15 | mV | ||

| ICC | Quiescent supply current | SD = 2 V, no load or filter, V(PVCC) = 12 V | 20 | 35 | mA | ||

| SD = 2 V, no load or filter, V(PVCC) = 24 V | 32 | 50 | |||||

| ICC(SD) | Quiescent supply current in shutdown mode | SD = 0.8 V, no load or filter, V(PVCC) = 12 V | <50 | µA | |||

| SD = 0.8 V, no load or filter, V(PVCC) = 24 V | 50 | 400 | |||||

| rDS(on) | Drain-source on-state resistance, measured pin-to-pin | V(PVCC) = 21 V, IO = 500 mA, TJ = 25°C | 120 | mΩ | |||

| G | Gain (BTL) | R1 = open, R2 = 20 kΩ | 19 | 20 | 21 | dB | |

| R1 = 100 kΩ, R2 = 20 kΩ | 25 | 26 | 27 | ||||

| R1 = 100 kΩ, R2 = 39 kΩ | 31 | 32 | 33 | dB | |||

| R1 = 75 kΩ, R2 = 47 kΩ | 35 | 36 | 37 | ||||

| G | Gain (SLV) | R1 = 51 kΩ, R2 = 51 kΩ | 19 | 20 | 21 | dB | |

| R1 = 47 kΩ, R2 = 75 kΩ | 25 | 26 | 27 | ||||

| R1 = 39 kΩ, R2 = 100 kΩ | 31 | 32 | 33 | dB | |||

| R1 = 16 kΩ, R2 = 100 kΩ | 35 | 36 | 37 | ||||

| ton | Turn-on time | V(SD) = 2 V | 10 | ms | |||

| toff | Turn-off time | V(SD) = 0.8 V | 2 | µs | |||

| GVDD | Gate drive supply | I(GVDD) < 200 µA | 6.4 | 6.9 | 7.4 | V | |

| VO | Output voltage maximum under PLIMIT control | V(PLIMIT) = 2 V; VI = 1 Vrms | 6.75 | 7.9 | 8.75 | V | |

6.6 AC Electrical Characteristics

TA = 25°C, AVCC = PVCC = 12 V to 24 V, RL = 4 Ω (unless otherwise noted)| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX | UNIT | |

|---|---|---|---|---|---|---|

| KSVR | Power supply ripple rejection | 200 mVPP ripple at 1 kHz, gain = 20 dB, inputs ac-coupled to GND | –70 | dB | ||

| PO | Continuous output power | THD+N = 10%, f = 1 kHz, V(PVCC) = 14.4 V | 25 | W | ||

| THD+N = 10%, f = 1 kHz, V(PVCC) = 21 V | 50 | |||||

| THD+N | Total harmonic distortion + noise | VCC = 21 V, f = 1 kHz, PO = 25 W (half-power) | 0.1% | |||

| Vn | Output integrated noise | 20 Hz to 22 kHz, A-weighted filter, gain = 20 dB | 65 | µV | ||

| –80 | dBV | |||||

| Crosstalk | VO = 1 Vrms, gain = 20 dB, f = 1 kHz | –100 | dB | |||

| SNR | Signal-to-noise ratio | Maximum output at THD+N < 1%, f = 1 kHz, gain = 20 dB, A-weighted | 102 | dB | ||

| fOSC | Oscillator frequency | AM[2:0] = 000 | 376 | 400 | 424 | kHz |

| AM[2:0] = 001 | 470 | 500 | 530 | |||

| AM[2:0] = 010 | 564 | 600 | 636 | |||

| AM[2:0] = 011 | 940 | 1000 | 1060 | |||

| AM[2:0] = 100 | 1128 | 1200 | 1278 | |||

| AM[2:0] = 101 | Reserved | |||||

| AM[2:0] = 110 | ||||||

| AM[2:0] = 111 | ||||||

| Thermal trip point | 150 | °C | ||||

| Thermal hysteresis | 15 | °C | ||||

| Overcurrent trip point | 7.5 | A | ||||

6.7 Timing Requirements

| MIN | NOM | MAX | UNIT | ||

|---|---|---|---|---|---|

| td | Delay from MUTE rising to SD falling | 1.4 | s | ||

Figure 1. Timing Requirement for SD

Figure 1. Timing Requirement for SD

6.8 Typical Characteristics

fs = 400 kHz, BD mode (unless otherwise noted)

| Gain = 26 dB | PVCC = 6 V | TA = 25°C |

| RL = 4 Ω | 10-µH + 0.68-µF filter | |

| Gain = 26 dB | PVCC = 6 V | TA = 25°C |

| RL = 4 Ω | 10-µH + 0.68-µF filter | |

| Gain = 26 dB | PVCC = 14.4 V | TA = 25°C |

| RL = 4 Ω | 10-µH + 0.68-µF filter |

| Gain = 26 dB | TA = 25°C | RL = 4 Ω |

| 10-µH + 0.68-µF filter | ||

| Gain = 26 dB | PVCC = 14.4 V | TA = 25°C |

| RL = 4 Ω | 22-µH + 1-µF filter | |

| Gain = 26 dB | PVCC = 14.4 V | TA = 25°C |

| RL = 4 Ω | 10-µH + 0.68-µF filter | |

| Gain = 26 dB | PVCC = 14.4 V | TA = 25°C |

| RL = 4 Ω | 10-µH + 0.68-µF filter | |

| Gain = 26 dB | TA = 25°C | RL = 4 Ω |

| 10-µH + 0.68-µF filter | ||

| Gain = 26 dB | PVCC = 12 V | TA = 25°C |

| RL = 4 Ω | 10-µH + 0.68-µF filter | |

| PVCC = 14.4 V | TA = 25°C | RL = 4 Ω |

| 22-µH + 3.3-µF filter | ||

7 Detailed Description

7.1 Overview

The TPA311xD2-Q1 devices are highly efficient class-D audio amplifiers with integrated 120-mΩ MOSFETs that allow output currents up to 7.5 A. The high efficiency allows the amplifier to provide an excellent audio performance without the need for a bulky heat sink.

The device can be configured for either master or slave operation by using the SYNC pin. Doing so helps to prevent audible beat noise.

7.2 Functional Block Diagram

7.3 Feature Description

7.3.1 Gain Setting and Master and Slave

The gain of the TPA311xD2-Q1 family is set by the voltage divider connected to the GAIN/SLV control pin. Master or slave mode is also controlled by the same pin. An internal ADC is used to detect the eight input states. The first four stages set the GAIN in master mode to gains of 20, 26, 32, and 36 dB, respectively, whereas the next four stages set the GAIN in slave mode to gains of 20, 26, 32, and 36 dB, respectively. The gain setting is latched during power up and cannot be changed while device is powered. Table 1 lists the recommended resistor values and the state and gain.

Table 1. Gain and Master or Slave

| MASTER / SLAVE MODE | GAIN | R1 (to GND)(1) | R2 (to GVDD)(1) | INPUT IMPEDANCE |

|---|---|---|---|---|

| Master | 20 dB | 5.6 kΩ | OPEN | 60 kΩ |

| Master | 26 dB | 20 kΩ | 100 kΩ | 30 kΩ |

| Master | 32 dB | 39 kΩ | 100 kΩ | 15 kΩ |

| Master | 36 dB | 47 kΩ | 75 kΩ | 9 kΩ |

| Slave | 20 dB | 51 kΩ | 51 kΩ | 60 kΩ |

| Slave | 26 dB | 75 kΩ | 47 kΩ | 30 kΩ |

| Slave | 32 dB | 100 kΩ | 39 kΩ | 15 kΩ |

| Slave | 36 dB | 100 kΩ | 16 kΩ | 9 kΩ |

Figure 12. Gain, Master or Slave

Figure 12. Gain, Master or Slave

In master mode, the SYNC terminal is an output, in slave mode, SYNC terminal is an input for a clock input.

7.3.2 Input Impedance

The input stage of the TPA311xD2-Q1 family is a fully differential input stage, and the input impedance changes with the gain setting from 9 kΩ at 36-dB gain to 60 kΩ at 20-dB gain. Table 1 lists the values from mininimum to maximum gain. The tolerance of the input resistor value is ±20%, so the minimum value is higher than 7.2 kΩ. The inputs must be ac-coupled to minimize the output dc offset and ensure correct ramping of the output voltages during power ON and power OFF. The input ac-coupling capacitor together with the input impedance forms a high-pass filter with the following cutoff frequency:

If a flat bass response is required down to 20 Hz, the recommended cutoff frequency is a tenth of that, 2 Hz. Table 2 lists the recommended ac-coupling capacitors for each gain step. If –3 dB is accepted at 20 Hz, 10 times lower capacitors can used – for example, a 1 µF can be used.

Table 2. Recommended Input AC-Coupling Capacitors

| GAIN | INPUT IMPEDANCE | INPUT CAPACITANCE | HIGH-PASS FILTER |

|---|---|---|---|

| 20 dB | 60 kΩ | 1.5 µF | 1.8 Hz |

| 26 dB | 30 kΩ | 3.3 µF | 1.6 Hz |

| 32 dB | 15 kΩ | 5.6 µF | 2.3 Hz |

| 36 dB | 9 kΩ | 10 µF | 1.8 Hz |

Figure 13. Input Impedance

Figure 13. Input Impedance

The input capacitors used should be a type with low leakage, like quality electrolytic, tantalum, or ceramic. If a polarized type is used, the positive connection should face the input pins, which are biased to 3 Vdc.

7.3.3 Start-Up and Shutdown Operation

The TPA311xD2-Q1 family employs a shutdown mode of operation designed to reduce supply current (ICC) to the absolute minimum level for power conservation during periods of nonuse. The SD input pin should be held high (see Recommended Operating Conditions for SD VIH and VIL levels) during normal operation when the amplifier is in use. Pulling SD low sets the outputs to mute, and the amplifier enters a low-current state. It is not recommended to leave SD unconnected, because amplifier operation would be unpredictable.

For the best power-off pop performance, place the amplifier in the shutdown mode prior to removing the power supply. The gain setting is selected at the end of the start-up cycle. At the end of the start-up cycle, the gain is selected and cannot be changed until the next power up.

7.3.4 PLIMIT Operation

The TPA311xD2-Q1 family has a built-in voltage limiter that can be used to limit the output voltage level below the supply rail, the amplifier simply operates as if it was powered by a lower supply voltage, and thereby limits the output power. Add a resistor divider from GVDD to ground to set the voltage at the PLIMIT pin. An external reference may also be used if tighter tolerance is required. Add a 1-µF capacitor from the PLIMIT pin to ground to ensure stability. It is recommended to connect PLIMIT to GVDD when using 1SPW-modulation mode.

Figure 14. Power Limit Example

Figure 14. Power Limit Example

The PLIMIT circuit sets a limit on the output peak-to-peak voltage. The limiting is done by limiting the duty cycle to a fixed maximum value. This limit can be thought of as a virtual voltage rail which is lower than the supply connected to PVCC. This virtual rail is approximately 4 times the voltage at the PLIMIT pin. This output voltage can be used to calculate the maximum output power for a given maximum input voltage and speaker impedance.

where

- POUT (10%THD) = 1.25 × POUT (unclipped)

- RL is the load resistance.

- RS is the total series resistance including RDS(on) and output filter resistance.

- VP is the peak amplitude

- VP = 4 × PLIMIT voltage if PLIMIT < 4 × VP

Table 3. Power Limit Example

| PVCC (V) | PLIMIT VOLTAGE (V)(1) | R to GND | R to GVDD | OUTPUT VOLTAGE (Vrms) |

|---|---|---|---|---|

| 24 V | GVDD | Open | Short | 17.9 |

| 24 V | 3.3 | 45 kΩ | 51 kΩ | 12.67 |

| 24 V | 2.25 | 24 kΩ | 51 kΩ | 9 |

| 12 V | GVDD | Open | Short | 10.33 |

| 12 V | 2.25 | 24 kΩ | 51 kΩ | 9 |

| 12 V | 1.5 | 18 kΩ | 68 kΩ | 6.3 |

7.3.5 GVDD Supply

The GVDD supply is used to power the gates of the output full-bridge transistors. The GVDD supply can also be used to supply the PLIMIT and GAIN/SLV voltage dividers. Decouple GVDD with an X5R ceramic 1-µF capacitor to GND. The GVDD supply is not intended to be used for external supply. It is recommended to limit the current consumption by using resistor voltage dividers of 100 kΩ or more for GAIN/SLV and PLIMIT.

7.3.6 BSPx and BSNx Capacitors

The full H-bridge output stages use only NMOS transistors. Therefore, to turn on correctly they require bootstrap capacitors for the high side of each output. A 220-nF ceramic capacitor of quality X5R or better, rated for at least 16 V, must be connected from each output to its corresponding bootstrap input. (See the application circuit diagram in Figure 19.) The bootstrap capacitors connected between the BSxx pins and their corresponding outputs function as a floating power supply for the high-side N-channel power MOSFET gate-drive circuitry. During each high-side switching cycle, the bootstrap capacitors hold the gate-to-source voltage high enough to keep the high-side MOSFETs turned on.

7.3.7 Differential Inputs

The differential input stage of the amplifier cancels any noise that appears on both input lines of the channel. To use the TPA311xD2-Q1 family with a differential source, connect the positive lead of the audio source to the RINP or LINP input and the negative lead from the audio source to the RINN or LINN input. To use the TPA311xD2-Q1 family with a single-ended source, ac-ground the negative input through a capacitor equal in value to the input capacitor on the positive input and apply the audio source to either input. In a single-ended input application, the unused input should be ac-grounded at the audio source instead of at the device input for best noise performance. For good transient performance, the impedance seen at each of the two differential inputs should be the same.

The impedance seen at the inputs should be limited to an RC time constant of 1 ms or less if possible. This is to allow the input dc-blocking capacitors to become completely charged during the 10-ms power-up time. If the input capacitors are not allowed to completely charge, there is some additional sensitivity to component matching which can result in a pop if the input components are not well matched.

7.3.8 Device Protection System

The TPA311xD2-Q1 family contains a complete set of protection circuits to make system design efficient as well as to protect the device against any kind of permanent failures due to short circuits, overload, overtemperature, and undervoltage. The FAULT pin signals if an error is detected according to Table 4:

Table 4. Fault Reporting

| FAULT | TRIGGERING CONDITION (typical value) |

FAULT | ACTION | LATCHED OR SELF-CLEARING |

|---|---|---|---|---|

| Overcurrent | Output short or short to PVCC or GND | Low | Output high impedance | Latched |

| Overtemperature | Tj > 150°C | Low | Output high impedance | Latched |

| Too-high dc offset | DC output voltage | Low | Output high impedance | Latched |

| Undervoltage on PVCC | V(PVCC) < 4.5 V | – | Output high impedance | Self-clearing |

| Overvoltage on PVCC | V(PVCC) > 27 V | – | Output high impedance | Self-clearing |

7.3.9 DC-Detect Protection

The TPA311xD2-Q1 family has circuitry which protects the speakers from dc current, which might occur due to defective capacitors on the input or shorts on the printed circuit board at the inputs. A dc-detect fault is reported on the FAULT pin as a low state. The dc-detect fault also causes the amplifier to shut down by changing the state of the outputs to Hi-Z.

If automatic recovery from the short-circuit protection latch is desired, connect the FAULT pin directly to the SD pin. This allows the FAULT pin function to automatically drive the SD pin low which clears the dc-detect protection latch.

A dc-detect fault is issued when the output differential duty-cycle of either channel exceeds 60% for more than 420 ms at the same polarity. For several values of the supply voltage, Table 5 shows some examples of the typical output offset voltages that trigger dc-detect protection. This feature protects the speaker from large dc currents or ac currents less than 2 Hz. To avoid nuisance faults due to the dc-detect circuit, hold the SD pin low at power up until the signals at the inputs are stable. Also, take care to match the impedance seen at the positive and negative inputs to avoid nuisance dc-detect faults.

Table 5 lists the minimum output offset voltages required to trigger the dc detect. The outputs must remain at or above the voltage listed in the table for more than 420 ms to trigger the dc detect.

Table 5. DC Detect Threshold

| V(PVCC) (V) | VOS - OUTPUT OFFSET VOLTAGE (V) |

|---|---|

| 4.5 | 0.96 |

| 6 | 1.3 |

| 12 | 2.6 |

| 18 | 3.9 |

7.3.10 Short-Circuit Protection and Automatic Recovery Feature

The TPA311xD2-Q1 family has protection from overcurrent conditions caused by a short circuit on the output stage. The short-circuit protection fault is reported on the FAULT pin as a low state. The amplifier outputs are switched to a high-impedance state when the short-circuit protection latch is engaged. The latch can be cleared by cycling the SD pin through the low state.

If automatic recovery from the short-circuit protection latch is desired, connect the FAULT pin directly to the SD pin. This allows the FAULT pin function to automatically drive the SD pin low, which clears the short-circuit protection latch.

In systems where a possibility of a permanent short from the output to PVDD or to a high-voltage battery like a car battery can occur, pull the MUTE pin low with the FAULT signal and an inverting transistor to ensure a high-Z restart, as shown in Figure 15.

Figure 15. MUTE Driven by Inverted FAULT

Figure 15. MUTE Driven by Inverted FAULT

7.3.11 Thermal Protection

Thermal protection on the TPA311xD2-Q1 family prevents damage to the device when the internal die temperature exceeds 150°C. There is a ±15°C tolerance on this trip point from device to device. Once the die temperature exceeds the thermal trip point, the device enters the shutdown state and the outputs are disabled. This is a latched fault.

Thermal protection faults are reported on the FAULT pin as a low state.

If automatic recovery from the thermal protection latch is desired, connect the FAULT pin directly to the SD pin. This allows the FAULT pin function to automatically drive the SD pin low, which clears the thermal protection latch.

7.3.12 TPA311xD2-Q1 Modulation Scheme

The TPA311xD2-Q1 family has the option of running in either BD modulation or 1SPW modulation; this is set by the MODSEL pin.

7.3.12.1 MODSEL = GND: BD Modulation

Each output is switching from 0 volts to the supply voltage. The OUTPx and OUTNx are in phase with each other with no input so that there is little or no current in the speaker. The duty cycle of OUTPx is greater than 50% and OUTNx is less than 50% for positive output voltages. The duty cycle of OUTPx is less than 50% and OUTNx is greater than 50% for negative output voltages. The voltage across the load sits at 0 V throughout most of the switching period, reducing the switching current, which reduces any I2R losses in the load.

Figure 16. BD Mode Modulation

Figure 16. BD Mode Modulation

7.3.12.2 MODSEL = HIGH: 1SPW Modulation

The 1SPW mode alters the normal modulation scheme in order to achieve higher efficiency with a slight penalty in THD degradation, and more attention required in the output filter selection. In 1SPW mode, the outputs operate at approximately 15% modulation during idle conditions. When an audio signal is applied, one output decreases and one increases. The decreasing output signal quickly rails to GND at which point all the audio modulation takes place through the rising output. The result is that only one output is switching during a majority of the audio cycle. Efficiency is improved in this mode due to the reduction of switching losses. The THD penalty in 1SPW mode is minimized by the high-performance feedback loop. The resulting audio signal at each half-output has a discontinuity each time the output rails to GND. This can cause ringing in the audio reconstruction filter unless care is taken in the selection of the filter components and type of filter used.

Figure 17. 1SPW Mode Modulation

Figure 17. 1SPW Mode Modulation

7.3.13 AM Avoidance EMI Reduction

To reduce interference in the AM radio band, the TPA3116D2-Q1 has the ability to change the switching frequency via the AM[2:0] pins. The recommended frequencies are listed in Table 6. The fundamental frequency and its second harmonic straddle the AM radio band listed. This eliminates the tones that can be present due to the switching frequency being demodulated by the AM radio.

Table 6. AM Frequencies

| US | EUROPEAN | ||||

|---|---|---|---|---|---|

| AM FREQUENCY (kHz) | AM FREQUENCY (kHz) | SWITCHING FREQUENCY (kHz) | AM2 | AM1 | AM0 |

| 522–540 | |||||

| 540–917 | 540–914 | 500 | 0 | 0 | 1 |

| 917–1125 | 914–1122 | 600 (or 400) | 0 | 1 | 0 |

| 0 | 0 | 0 | |||

| 1125–1375 | 1122–1373 | 500 | 0 | 0 | 1 |

| 1375–1547 | 1373–1548 | 600 (or 400) | 0 | 1 | 0 |

| 0 | 0 | 0 | |||

| 1547–1700 | 1548–1701 | 600 (or 500) | 0 | 1 | 0 |

| 0 | 0 | 1 | |||

7.4 Device Functional Mode

7.4.1 Mono Mode (PBTL)

The TPA311xD2-Q1 family can be connected in MONO mode enabling up to 100-W output power. This is done by:

- Connecting INPL and INNL directly to ground (without capacitors) to set the device in mono mode during power up

- Connecting OUTPR and OUTNR together for the positive speaker terminal and OUTNL and OUTPL together for the negative terminal

- Applying the analog input signal to INPR and INNR

Figure 18. Mono Mode (PBTL)

Figure 18. Mono Mode (PBTL)

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

This section describes a 2.1 master-and-slave application. The master is configured as stereo outputs and the slave is configured as a mono PBTL output.

8.2 Typical Application

A 2.1 solution, U1 TPA3116D2-Q1 in master mode 400 kHz, BTL, gain if 20 dB, power limit not implemented. U2 in Slave, PBTL mode gain of 20 dB. Inputs are connected for differential inputs.

Figure 19. Typical Application Schematic

Figure 19. Typical Application Schematic

8.2.1 Design Requirements

| DESIGN PARAMETERS | EXAMPLE VALUE |

|---|---|

| Input voltage range, V(PVCC) | 4.5 V to 26 V |

| PWM output frequencies | 400 kHz, 500 kHz, 600 kHz, 1 MHz or 1.2 MHz |

| Maximum output power | 50 W |

8.2.2 Detailed Design Procedure

The TPA311xD2-Q1 family is a very flexible and easy-to-use class-D amplifier; therefore, the design process is straightforward. Before beginning the design, gather the following information regarding the audio system.

- PVCC rail planned for the design

- Speaker or load impedance

- Maximum output-power requirement

- Desired PWM frequency

8.2.2.1 Select the PWM Frequency

Set the PWM frequency by using AM0, AM1 and AM2 pins.

8.2.2.2 Select the Amplifier Gain and Master or Slave Mode

In order to select the amplifier gain setting, the designer must determine the maximum power target and the speaker impedance. Once these parameters have been determined, calculate the required output-voltage swing which delivers the maximum output power.

Choose the lowest analog gain setting that produces an output-voltage swing greater than the required output swing for maximum power. The analog gain and master or slave mode can be set by selecting the voltage divider resistors (R1 and R2) on the GAIN/SLV pin.

8.2.2.3 Select Input Capacitance

Select the bulk capacitors at the PVCC inputs for proper voltage margin and adequate capacitance to support the power requirements. In practice, with a well-designed power supply, two 100-μF, 50-V capacitors should be sufficient. One capacitor should be placed near the PVCC inputs at each side of the device. PVCC capacitors should be a low-ESR type because they are being used in a high-speed switching application.

8.2.2.4 Select Decoupling Capacitors

Good-quality decoupling capacitors must be added at each of the PVCC inputs to provide good reliability, good audio performance, and to meet regulatory requirements. X5R or better ratings should be used in this application. Consider temperature, ripple current, and voltage overshoots when selecting decoupling capacitors. Also, these decoupling capacitors should be located near the PVCC and GND connections to the device in order to minimize series inductances.

8.2.2.5 Select Bootstrap Capacitors

Each of the outputs requires bootstrap capacitors to provide gate drive for the high-side output FETs. For this design, use 0.22-μF, 25-V capacitors of X5R quality or better.

8.2.3 Application Curves

| Gain = 26 dB | PVCC = 12 V | TA = 25°C |

| RL = 4 Ω | 10-µH + 0.68-µF filter | |

| Gain = 26 dB | PVCC = 14.4 V | TA = 25°C |

| RL = 4 Ω | 10-µH + 0.68-µF filte | |

9 Power Supply Recommendations

The power supply requirements for the TPA3116D2-Q1 consist of one higher-voltage supply to power the output stage of the speaker amplifier. Several on-chip regulators are included on the TPA3116D2-Q1 to generate the voltages necessary for the internal circuitry of the audio path. It is important to note that the voltage regulators which have been integrated are sized only to provide the current necessary to power the internal circuitry. The external pins are provided only as a connection point for off-chip bypass capacitors to filter the supply. Connecting external circuitry to these regulator outputs may result in reduced performance and damage to the device. The high-voltage supply, between 4.5 V and 26 V, supplies the analog circuitry (AVCC) and the power stage (PVCC). The AVCC supply feeds the internal LDOs, including GVDD. The LDO outputs are connected to external pins for filtering purposes, but should not be connected to external circuits. The GVDD LDO output has been sized to provide current necessary for internal functions but not for external loading.

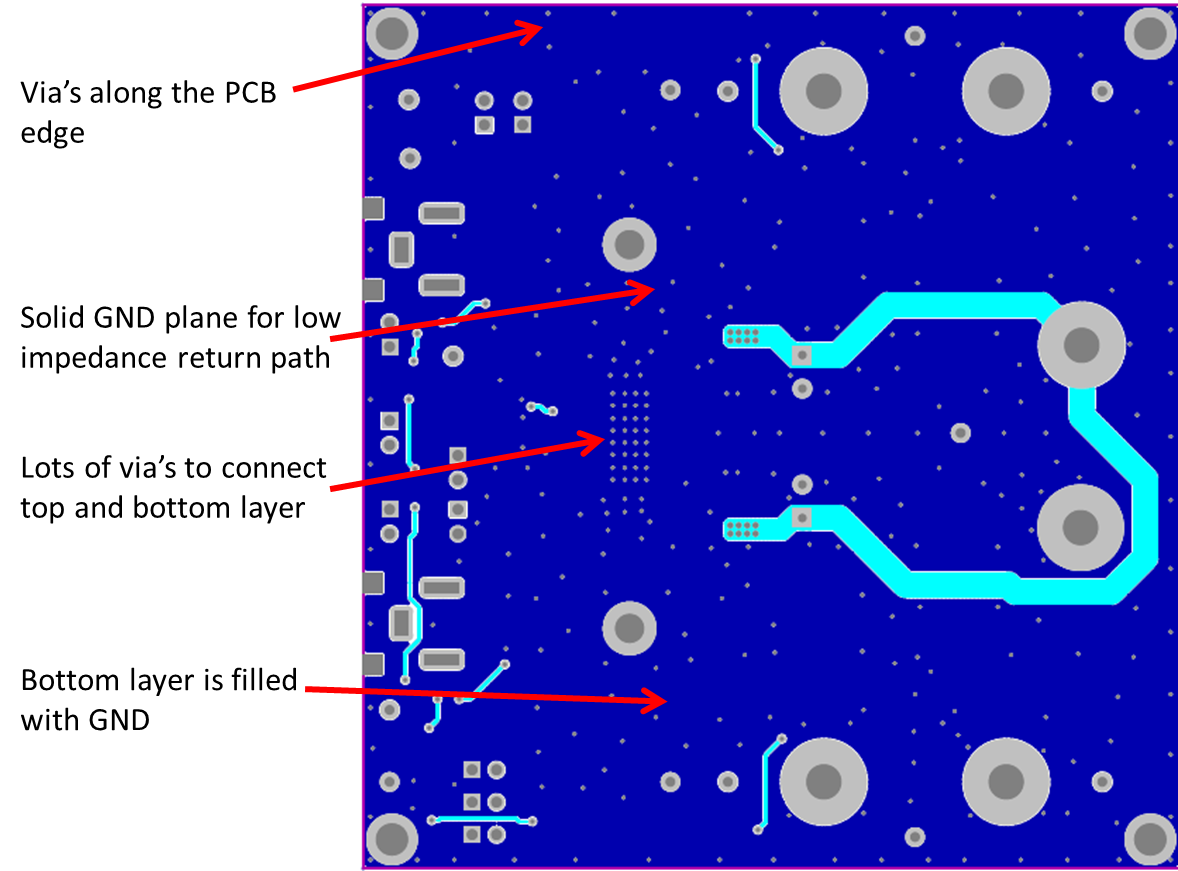

10 Layout

10.1 Layout Guidelines

Because the class-D switching edges are fast, it is necessary to take care when planning the layout of the printed circuit board. The following suggestions help to meet EMC requirements.

- Decoupling capacitors — The high-frequency decoupling capacitors should be placed as close to the PVCC and AVCC terminals as possible. Large (100 μF or greater) bulk power supply decoupling capacitors should be placed near the TPA3116D2-Q1 on the PVCC supplies. Local, high-frequency bypass capacitors should be placed as close to the PVCC pins as possible. These capacitors can be connected to the IC GND pad directly for an excellent ground connection. Consider adding a small, good-quality, low-ESR ceramic capacitor between 220 pF and 1 nF and a larger mid-frequency capacitor of value between 100 nF and 1 µF, also of good quality, to the PVCC connections at each end of the chip.

- Keep the current loop from each of the outputs through the filter and back to GND as small and tight as possible. The size of this current loop determines its effectiveness as an antenna.

- Grounding — The PVCC decoupling capacitors should connect to GND. All ground should be connected at the IC GND, which should be used as a central ground connection or star ground for the TPA3116D2-Q1.

- Output filter — The LC filter should be placed close to the outputs. The capacitor used in the LC filter should be grounded.

For an example layout, see the TPA3116D2 Evaluation Module (TPA3116D2EVM) User Guide (SLOU336). Both the EVM user manual and the thermal pad application reports, SLMA002 and SLMA004, are available on the TI Web site at http://www.ti.com.

10.2 Layout Example

Figure 22. Layout Example Top

Figure 22. Layout Example Top

Figure 23. Layout Example Bottom

Figure 23. Layout Example Bottom

10.3 Heat Sink Used on the EVM

The heat sink (part number ATS-TI 10 OP-521-C1-R1 or equivalent) used on the EVM is a 14-mm × 25-mm × 50-mm extruded aluminum heat sink with three fins (see Figure 24). For additional information on the heat sink, go to www.qats.com.

Figure 24. EVM Heatsink

Figure 24. EVM Heatsink

This size heat sink has shown to be sufficient for continuous output power. The crest factor of music and having airflow lowers the requirement for heat sinking, and smaller types of heat sinks can be used.

11 Device and Documentation Support

11.1 Device Support

11.1.1 Third-Party Products Disclaimer

TI'S PUBLICATION OF INFORMATION REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT CONSTITUTE AN ENDORSEMENT REGARDING THE SUITABILITY OF SUCH PRODUCTS OR SERVICES OR A WARRANTY, REPRESENTATION OR ENDORSEMENT OF SUCH PRODUCTS OR SERVICES, EITHER ALONE OR IN COMBINATION WITH ANY TI PRODUCT OR SERVICE.

11.2 Related Links

The table below lists quick access links. Categories include technical documents, support and community resources, tools and software, and quick access to sample or buy.

Table 7. Related Links

| PARTS | PRODUCT FOLDER | SAMPLE & BUY | TECHNICAL DOCUMENTS | TOOLS & SOFTWARE | SUPPORT & COMMUNITY |

|---|---|---|---|---|---|

| TPA3116D2-Q1 | Click here | Click here | Click here | Click here | Click here |

| TPA3118D2-Q1 | Click here | Click here | Click here | Click here | Click here |

11.3 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. In the upper right corner, click on Alert me to register and receive a weekly digest of any product information that has changed. For change details, review the revision history included in any revised document.

11.4 Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of Use.

-

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help solve problems with fellow engineers.

-

Design Support TI's Design Support Quickly find helpful E2E forums along with design support tools and contact information for technical support.

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of Use.

-

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help solve problems with fellow engineers.

-

Design Support TI's Design Support Quickly find helpful E2E forums along with design support tools and contact information for technical support.

11.5 Electrostatic Discharge Caution

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

11.6 Trademarks

PowerPAD, E2E are trademarks of Texas Instruments.

All other trademarks are the property of their respective owners.

11.7 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most-current data available for the designated devices. This data is subject to change without notice and without revision of this document. For browser-based versions of this data sheet, see the left-hand navigation pane.

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and complete. All semiconductor products (also referred to herein as "components") are sold subject to TI's terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI's terms and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily performed.

TI assumes no liability for applications assistance or the design of Buyers' products. Buyers are responsible for their products and applications using TI components. To minimize the risks associated with Buyers' products and applications, Buyers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI's goal is to help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or "enhanced plastic" are designed and intended for use in military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products

- Audio: www.ti.com/audio

- Amplifiers: amplifier.ti.com

- Data Converters: dataconverter.ti.com

- DLP® Products: www.dlp.com

- DSP: dsp.ti.com

- Clocks and Timers: www.ti.com/clocks

- Interface: interface.ti.com

- Logic: logic.ti.com

- Power Mgmt: power.ti.com

- Microcontrollers: microcontroller.ti.com

- RFID: www.ti.rfid.com

- OMAP Application Processors: www.ti.com/omap

- Wireless Connectivity: www.ti.com/wirelessconnectivity

Applications

- Automotive and Transportation: www.ti.com/automotive

- Communications and Telecom: www.ti.com/communications

- Computers and Peripherals: www.ti.com/computers

- Consumer Electronics: www.ti.com/consumer-apps

- Energy and Lighting: www.ti.com/energy

- Industrial: www.ti.com/industrial

- Medical: www.ti.com/medical

- Security: www.ti.com/security

- Space, Avionics and Defense: www.ti.com/space-avionics-defense

- Video & Imaging: www.ti.com/video

TI E2E Community : e2e.ti.com

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright© 2016, Texas Instruments Incorporated