SLVSFQ6A November 2020 – June 2021 TPS2640

PRODUCTION DATA

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Parameter Measurement Information

-

9 Detailed Description

- 9.1 Overview

- 9.2 Functional Block Diagram

- 9.3

Feature Description

- 9.3.1 Undervoltage Lockout (UVLO)

- 9.3.2 Overvoltage Protection (OVP)

- 9.3.3 Reverse Input Supply Protection

- 9.3.4 Hot Plug-In and In-Rush Current Control

- 9.3.5 Overload and Short Circuit Protection

- 9.4 Device Functional Modes

-

10Application and Implementation

- 10.1 Application Information

- 10.2 Typical Application

- 10.3 System Examples

- 10.4 Do's and Dont's

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

Thermal pad, mechanical data (Package|Pins)

- PWP|16

Orderable Information

9.3.2 Overvoltage Protection (OVP)

The TPS26400 incorporate circuitry to protect the system during overvoltage conditions. A voltage more than V(OVPR) on OVP pin turns off the internal FET and protects the downstream load. To program the OVP threshold externally, connect a resistor divider from IN supply to OVP terminal to RTN as shown in Figure 9-1. The TPS26400 also feature a factory set 33-V Input overvoltage cut off V(IN_OVP) threshold with a 2-V hysteresis. This feature can be enabled by connecting the OVP terminal directly to the RTN terminal. Figure 7-26 illustrates the overvoltage cut-off functionality.

Programmable output overvoltage clamp can also be achieved using TPS26400 by connecting the resistor ladder

from Vout to OVP to RTN as shown in Figure 9-2 . This results in clamping of output voltage close to OVP setpoint

by resistors R4 and R5. as shown in Figure 9-3. This scheme will also help in achieving minimal system Iq

during off state. For this OVP configurataion, use R4 > 90 kΩ.

Figure 9-2 Programmable Output OV Clamp

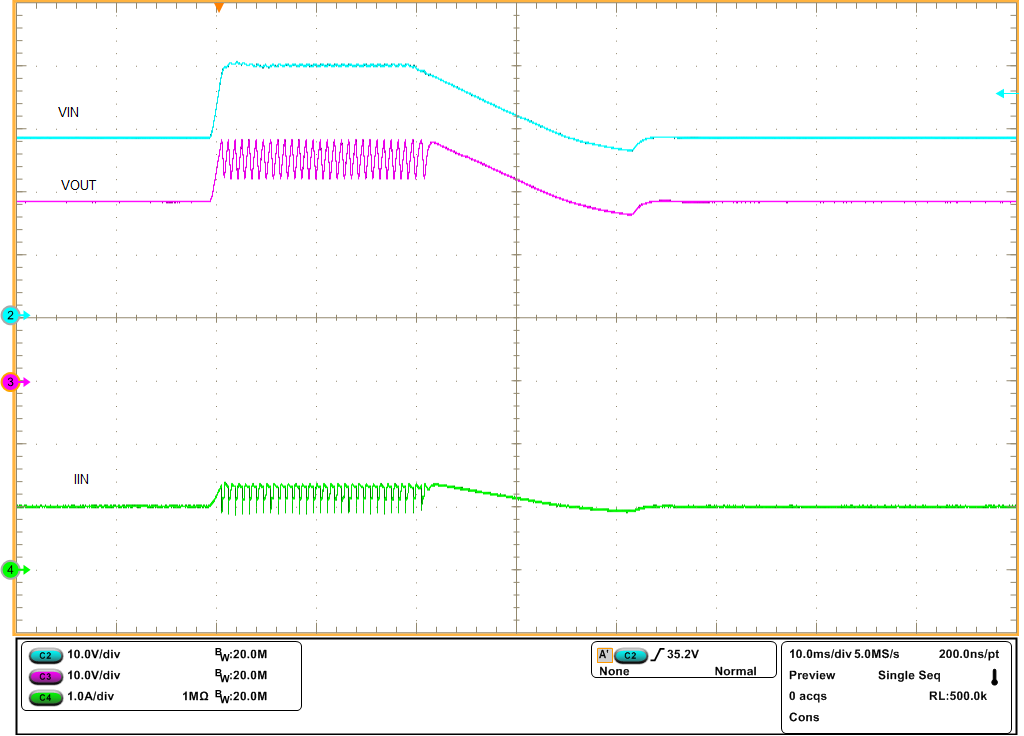

Figure 9-2 Programmable Output OV Clamp Figure 9-3 Programmable Output Overvoltage Clamp Response

Figure 9-3 Programmable Output Overvoltage Clamp Response