SLUSAK4D June 2011 – July 2015 TPS53317

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- RGB|20

Thermal pad, mechanical data (Package|Pins)

- RGB|20

Orderable Information

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

The TPS53317 device is a FET-integrated synchronous buck regulator designed mainly for DDR termination. It can provide a regulated output at ½ VDDQ with both sink and source capability. The device employs D-CAP+ mode operation that provides ease-of-use, low external component count and fast transient response.

8.2 Typical Applications

8.2.1 DDR4 SDRAM Application

This DDR4 application requires a tight load tolerance, fast transient response, and sinking current capability, the design uses a non-droop PWM configuration.

8.2.1.1 Design Requirements

- Input voltage : VIN = 1.2 V

- Output voltage: VOUT = 0.6 V

- Maximum load step size of 3 A @ slew rate 7 A/µs (–1.5 A to 1.5 A)

- DC +AC + Ripple voltage regulation limit at sense point: ±42 mV (0.642 V overshoot, 0.558 V undershoot)

- Maximum load: IMAX = 2.5 A

8.2.1.2 Detailed Design Procedure

8.2.1.2.1 Step 1. Determine Configuration

Because this DDR4 application requires a tight load tolerance, fast transient response, and sinking current capability, the design uses a non-droop PWM configuration. Choose 600-kHz switching frequency due to the duty cycle and minimim off-time of the device, and set an overcurrent (OC) valley limit of 5.4 A due to the maximum load requirement of 2.5 A. Referring to Table 1 select an RMODE value of 68 kΩ.

8.2.1.2.2 Step 2. Select Inductor

Smaller inductor values have better transient performance but higher ripple and lower efficiency. High values have the opposite characteristics. It is common practice to limit the ripple current to 30% to 50% of the maximum current. Choose 50% to allow use of a smaller inductor for faster transient performance.

where

- D = duty cycle

Because this device operates in DCAP+ mode, the frequency and duty cycle vary based on the input voltage, the output voltage and load. With a 2.5-A load, a 1.2-V input voltage and 0.60 V output voltage, fSW is experimentally measured at approximately 800 kHz and duty cycle of 0.55. Therefore L is calculated as shown in Equation 10.

Choose the closest standard value, 0.25 µH.

8.2.1.2.3 Step 3. Determine Output Capacitance

Use Equation 10 to calculate the output capacitance for a desired maximum overshoot.

where

- COUT(min),OS is the minimum output capacitance for a desired overshoot

- ΔIOUT is the maximum output current change in the application

- VOUT = desired output voltage

- VOS is the desired output voltage change due to overshoot

Choose a value of 30 mV to account for normal output voltage ripple.

Use Equation 12 to calculate the necessary output capacitance for a desired maximum undershoot.

where

- COUT(min),US is the minimum output capacitance for a desired undershoot

- VUS is the desired output voltage change due to overshoot

- tSW is the period of switch node

- tMIN(off) is the minimum off-time (270 ns)

Again, choose 30 mV to account for normal output voltage ripple.

The undershoot requirements determine, so there must be a minimum of 157.6 µF. Because this is a DDR application where size is also a consideration, this design uses only ceramic capacitors. To account for voltage de-rating of capacitors and provide additional margin, this design includes eleven 22-µF output capacitors.

8.2.1.2.4 Step 4. Input Capacitance

This design requires sufficient input capacitance to filter the input current from the host source. Use Equation 14 to calculate the necessary input capacitance.

where

- ΔVIN(P-P) is the desired input voltage ripple (typically 1% of the input voltage)

As with the output capacitance selection, this design accounts for voltage de-rating of capacitors and provides additional margin, using four 22-µF input capacitors.

8.2.1.2.5 Step 5. Compensation Network

In order to achieve stable operation, the crossover frequency should be less than 1/5 of the switching frequency.

where

- RS = 53 mΩ

Account for capacitor de-rating here and set the value of COUT to 160 µF, so that Equation 17 is true.

Choose an RC value of 3.9 kΩ. Determine CC by choosing the value of the zero created by RC and CC. Using the relationship described in Equation 18.

Equation 18 yields a CC value of 2.55 nF. Choose the closest common capacitor value of 2.2 nF. To determine a value for CP, first consider the relationship described in Equation 19.

where

- CC >> CP

Because CC >> CP , set the pole to be two times the switching frequency as described in Equation 20.

To boost the gain margin, set CP to 33 pF.

Figure 30. Compensation Network Circuit

Figure 30. Compensation Network Circuit

8.2.1.2.6 Peripheral Component Selection

As described in Table 1, connect a 0.22-µF capacitor from the VREF pin to GND and connect a 0.1-µF bootstrap capacitor from the SW pin to the BST pin. Because the PGOOD pin is open drain, connect a pullup resistor between it and the 5-V rail.

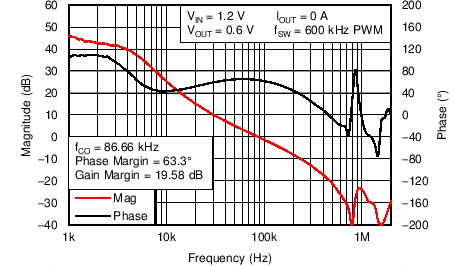

8.2.1.3 Application Curves

Figure 33. Bode Plot, No Load

Figure 33. Bode Plot, No Load

Figure 35. Switching Frequency vs. Load

Figure 35. Switching Frequency vs. Load

Figure 32. Load Transient

Figure 32. Load Transient

Figure 34. Bode Plot, Full Load

Figure 34. Bode Plot, Full Load

Figure 36. Load Regulation

Figure 36. Load Regulation

8.2.2 DDR3 SDRAM Application

8.2.2.1 Design Requirements

- VIN = 1.5 V

- VOUT = 0.75 V

8.2.3 Non-Tracking Point-of-Load (POL) Application

8.2.3.1 Design Requirements

- VIN = 3.3 V

- VOUT = 1.2 V

8.2.3.2 Application Curves

Figure 39. Bode Plot No Load

Figure 39. Bode Plot No Load

Figure 40. Bode Plot Full Load

Figure 40. Bode Plot Full Load