SLVSEZ9 January 2019 TPS54540B

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3

Feature Description

- 7.3.1 Fixed Frequency PWM Control

- 7.3.2 Slope Compensation Output Current

- 7.3.3 Pulse Skip Eco-mode

- 7.3.4 Low Dropout Operation and Bootstrap Voltage (BOOT)

- 7.3.5 Error Amplifier

- 7.3.6 Adjusting the Output Voltage

- 7.3.7 Enable and Adjusting Undervoltage Lockout

- 7.3.8 Internal Soft Start

- 7.3.9 Constant Switching Frequency and Timing Resistor (RT/CLK) pin)

- 7.3.10 Accurate Current-Limit Operation and Maximum Switching Frequency

- 7.3.11 Synchronization to RT/CLK pin

- 7.3.12 Overvoltage Protection

- 7.3.13 Thermal Shutdown

- 7.3.14 Small Signal Model for Loop Response

- 7.3.15 Simple Small Signal Model for Peak-Current-Mode Control

- 7.3.16 Small Signal Model for Frequency Compensation

- 7.4 Device Functional Modes

-

8 Application and Implementation

- 8.1 Application Information

- 8.2

Typical Application

- 8.2.1 Design Requirements

- 8.2.2

Detailed Design Procedure

- 8.2.2.1 Custom Design with WEBENCH® Tools

- 8.2.2.2 Selecting the Switching Frequency

- 8.2.2.3 Output Inductor Selection (LO)

- 8.2.2.4 Output Capacitor

- 8.2.2.5 Catch Diode

- 8.2.2.6 Input Capacitor

- 8.2.2.7 Bootstrap Capacitor Selection

- 8.2.2.8 Undervoltage Lockout Set Point

- 8.2.2.9 Output Voltage and Feedback Resistors Selection

- 8.2.2.10 Minimum VIN

- 8.2.2.11 Compensation

- 8.2.2.12 Discontinuous Conduction Mode and Eco-mode Boundary

- 8.2.2.13 Power Dissipation Estimate

- 8.2.2.14 Safe Operating Area

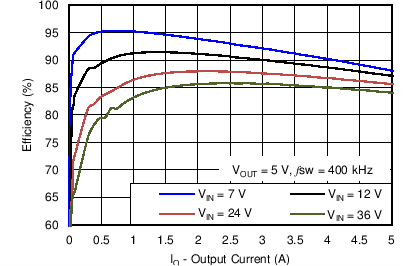

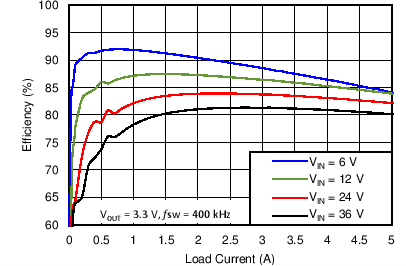

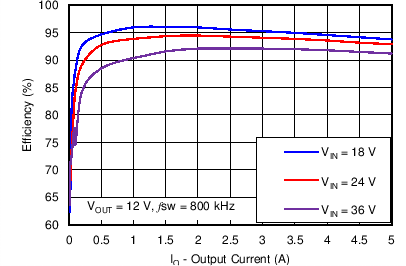

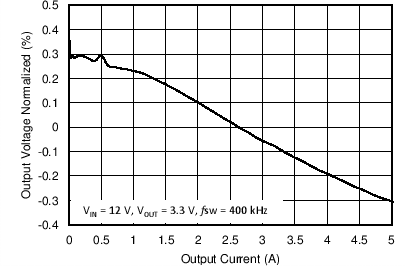

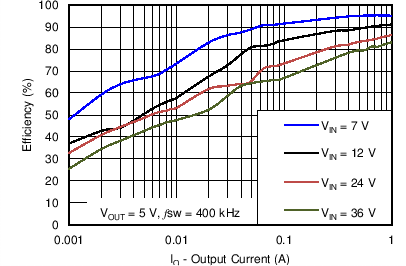

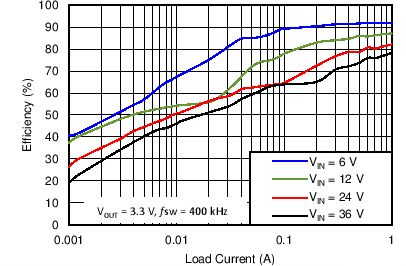

- 8.2.3 Application Curves

- 8.3 Other System Examples

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- DDA|8

Thermal pad, mechanical data (Package|Pins)

- DDA|8

Orderable Information

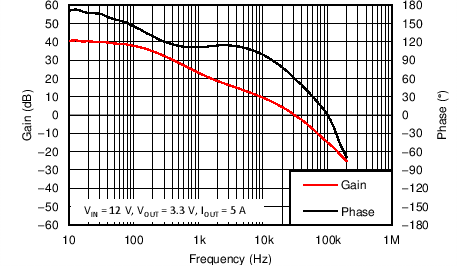

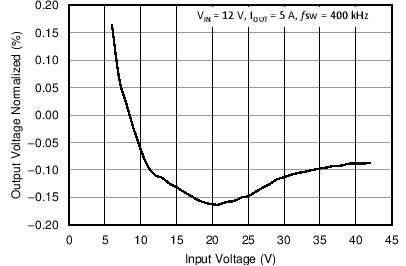

8.2.3 Application Curves

Measurements are taken with standard EVM using a 12-V input, 3.3-V output, and 5-A load unless otherwise noted.