SNVSAC7C October 2015 – May 2017 TPS61193-Q1

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

-

7 Specifications

- 7.1 Absolute Maximum Ratings

- 7.2 ESD Ratings

- 7.3 Recommended Operating Conditions

- 7.4 Thermal Information

- 7.5 Electrical Characteristics

- 7.6 Internal LDO Electrical Characteristics

- 7.7 Protection Electrical Characteristics

- 7.8 Current Sinks Electrical Characteristics

- 7.9 PWM Brightness Control Electrical Characteristics

- 7.10 Boost and SEPIC Converter Characteristics

- 7.11 Logic Interface Characteristics

- 7.12 Typical Characteristics

- 8 Detailed Description

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

Package Options

Mechanical Data (Package|Pins)

- PWP|20

Thermal pad, mechanical data (Package|Pins)

- PWP|20

Orderable Information

9 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

9.1 Application Information

The TPS61193-Q1 is designed for automotive applications, and an input voltage (VIN), intended to be connected to the automotive battery, supports input voltage range from 4.5 V to 40 V. Device internal circuitry is powered from the integrated LDO.

The TPS61193-Q1 uses a simple four-wire control:

- VDDIO/EN for enable

- PWM input for brightness control

- SYNC pin for boost synchronisation (optional)

- FAULT output to indicate fault condition (optional)

9.2 Typical Applications

9.2.1 Typical Application for 3 LED Strings

Figure 20 shows the typical application for TPS61193-Q1 which supports 3 LED strings with maximum current 100 mA, with a boost switching frequency of 300 kHz.

Figure 20. Three Strings 100 mA/String Configuration

Figure 20. Three Strings 100 mA/String Configuration

9.2.1.1 Design Requirements

| DESIGN PARAMETER | VALUE |

|---|---|

| VIN voltage range | 4.5 V – 28 V |

| LED string | 3P8S LEDs (30 V) |

| LED string current | 100 mA |

| Maximum boost voltage | 37 V |

| Boost switching frequency | 300 kHz |

| External boost sync | not used |

| Boost spread spectrum | enabled |

| L1 | 33 μH |

| CIN | 100 µF, 50 V |

| CIN BOOST | 2 × (10-µF, 50-V ceramic) + 33-µF, 50-V electrolytic |

| COUT | 2 × (10-µF, 50-V ceramic) + 33-µF, 50-V electrolytic |

| CFB | 15 pF |

| CLDO | 1 µF, 10 V |

| RISET | 24 kΩ |

| RFSET | 210 kΩ |

| R1 | 750 kΩ |

| R2 | 130 kΩ |

| R3 | 10 kΩ |

9.2.1.2 Detailed Design Procedure

9.2.1.2.1 Inductor Selection

There are two main considerations when choosing an inductor; the inductor must not saturate, and the inductor current ripple must be small enough to achieve the desired output voltage ripple. Different saturation current rating specifications are followed by different manufacturers so attention must be given to details. Saturation current ratings are typically specified at 25°C. However, ratings at the maximum ambient temperature of application should be requested from the manufacturer. Shielded inductors radiate less noise and are preferred. The saturation current must be greater than the sum of the maximum load current, and the worst case average-to-peak inductor current. Equation 4 shows the worst case conditions

where

- IRIPPLE - peak inductor current

- IOUTMAX - maximum load current

- VIN - minimum input voltage in application

- L - min inductor value including worst case tolerances

- f - minimum switching frequency

- VOUT - output voltage

- D - Duty Cycle for CCM Operation

As a result, the inductor should be selected according to the ISAT. A more conservative and recommended approach is to choose an inductor that has a saturation current rating greater than the maximum current limit. A saturation current rating of at least 2.5 A is recommended for most applications. See Table 2 for recommended inductance value for the different switching frequency ranges. The inductor’s resistance should be less than

300 mΩ for good efficiency.

See detailed information in Understanding Boost Power Stages in Switch Mode Power Supplies. Power Stage Designer™ Tool can be used for the boost calculation: http://www.ti.com/tool/powerstage-designer.

9.2.1.2.2 Output Capacitor Selection

A ceramic capacitor with 2 × VMAX BOOST or more voltage rating is recommended for the output capacitor. The DC-bias effect can reduce the effective capacitance by up to 80%, which needs to be considered in capacitance value selection. Capacitance recommendations for different switching frequencies are shown in Table 2. To minimize audible noise of ceramic capacitors their physical size should typically be minimized.

9.2.1.2.3 Input Capacitor Selection

A ceramic capacitor with 2 × VIN MAX or more voltage rating is recommended for the input capacitor. The DC-bias effect can reduce the effective capacitance by up to 80%, which needs to be considered in capacitance value selection. Capacitance recommendations for different boost switching frequencies are shown in Table 2.

9.2.1.2.4 LDO Output Capacitor

A ceramic capacitor with at least 10-V voltage rating is recommended for the output capacitor of the LDO. The DC-bias effect can reduce the effective capacitance by up to 80%, which needs to be considered in capacitance value selection. Typically a 1-µF capacitor is sufficient.

9.2.1.2.5 Diode

A Schottky diode should be used for the boost output diode. Do not use ordinary rectifier diodes because slow switching speeds and long recovery times degrade the efficiency and the load regulation. Diode rating for peak repetitive current should be greater than inductor peak current (up to 3 A) to ensure reliable operation in boost mode. Average current rating should be greater than the maximum output current. Schottky diodes with a low forward drop and fast switching speeds are ideal for increasing efficiency. Choose a reverse breakdown voltage of the Schottky diode significantly larger than the output voltage.

9.2.1.3 Application Curves

| Load 3 strings, 8 LEDs per string | ƒsw = 300 kHz, 33 μH | |

| 100 mA/string for VIN = 12 V and VIN = 16 V | ||

| 60 mA/string for VIN = 8 V | ||

| 50 mA/string for VIN = 5 V | ||

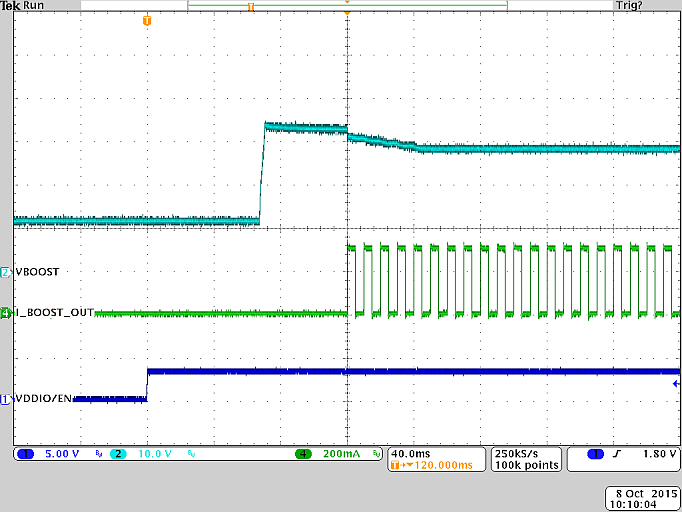

Figure 23. Typical Start-Up

Figure 23. Typical Start-Up

| Load 3 strings, 8 LEDs per string | ƒsw = 300 kHz, 33 μH | |

| 100 mA/string for VIN = 12 V and VIN = 16 V | ||

| 60 mA/string for VIN = 8 V | ||

| 50 mA/string for VIN = 5 V | ||

9.2.2 SEPIC Mode Application

When LED string voltage can be above or below VIN voltage, SEPIC configuration can be used. In this example, two separate coils are used for SEPIC. This can enable lower height external components to be used, compared to a coupled coil solution. On the other hand, coupled coil typically maximizes the efficiency. Also, in this example, an external clock is used to synchronize SEPIC switching frequency. External clock input can be modulated to spread switching frequency spectrum.

Figure 25. SEPIC Mode, 3 Strings, 100 mA/String Configuration

Figure 25. SEPIC Mode, 3 Strings, 100 mA/String Configuration

9.2.2.1 Design Requirements

| DESIGN PARAMETER | VALUE |

|---|---|

| VIN voltage range | 4.5 V – 30 V |

| LED string | 3P2S LEDs (7.2 V) |

| LED string current | 100 mA |

| Maxmum output voltage | 10 V |

| SEPIC switching frequency | 2.2 MHz |

| External sync for SEPIC | used |

| Spread spectrum | Internal spread spectrum disabled (external sync used) |

| L1, L2 | 10 µH |

| CIN | 10 µF 50 V |

| CIN SEPIC | 2 × 10-µF, 50-V ceramic + 33 µF 50-V electrolytic |

| C1 | 10-µF 50-V ceramic |

| COUT | 2 × 10-µF, 50-V ceramic + 33 µF 50-V electrolytic |

| CLDO | 1 µF, 10 V |

| RISET | 24 kΩ |

| RFSET | 24 kΩ |

| R1 | 184 kΩ |

| R2 | 130 kΩ |

| R3 | 10 kΩ |

9.2.2.2 Detailed Design Procedure

In SEPIC mode the maximum voltage at the SW pin is equal to the sum of the input voltage and the output voltage. Because of this, the maximum sum of input and output voltage must be limited below 50 V. See Detailed Design Procedure for general external component guidelines. Main differences of SEPIC compared to boost are described below.

Power Stage Designer™ Tool can be used for modeling SEPIC behavior: http://www.ti.com/tool/powerstage-designer. For detailed explanation on SEPIC see Texas Instruments Analog Applications Journal Designing DC/DC Converters Based on SEPIC Topology.

9.2.2.2.1 Inductor

In SEPIC mode, currents flowing through the coupled inductors or the two separate inductors L1 and L2 are the input current and output current, respectively. Values can be calculated using Power Stage Designer™ Tool or using equations in Designing DC/DC Converters Based on SEPIC Topology.

9.2.2.2.2 Diode

In SEPIC mode diode peak current is equal to the sum of input and output currents. Diode rating for peak repetitive current should be greater than SW pin current limit (up to 3 A for transients) to ensure reliable operation in boost mode. Average current rating should be greater than the maximum output current. Diode voltage rating must be higher than sum of input and output voltages.

9.2.2.2.3 Capacitor C1

Ti recommends a ceramic capacitor with low ESR. Diode voltage rating must be higher than maximum input voltage.

9.2.2.3 Application Curves

| Load 100mA per string, 3 strings, 2 LEDs per string | ||

| ƒsw = 2.2 MHz | ||

| 2 × 10 μH, IHLP2525BDER100M | ||

| Load 100mA per string, 3 strings, 2 LEDs per string | |

| ƒsw = 2.2 MHz | |

| 2 × 10 μH, IHLP2525BDER100M |