SLUSDC0D October 2018 – November 2024 UCC21530

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Pin Configuration and Functions

-

5 Specifications

- 5.1 Absolute Maximum Ratings

- 5.2 ESD Ratings

- 5.3 Recommended Operating Conditions

- 5.4 Thermal Information

- 5.5 Power Ratings

- 5.6 Insulation Specifications

- 5.7 Safety Limiting Values

- 5.8 Electrical Characteristics

- 5.9 Timing Requirements

- 5.10 Switching Characteristics

- 5.11 Insulation Characteristics Curves

- 5.12 Typical Characteristics

- 6 Parameter Measurement Information

- 7 Detailed Description

-

8 Application and Implementation

- 8.1 Application Information

- 8.2

Typical Application

- 8.2.1 Design Requirements

- 8.2.2 Detailed Design Procedure

- 8.2.3 Application Curves

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Revision History

- 13Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- DWK|14

Thermal pad, mechanical data (Package|Pins)

Orderable Information

8.2.2.7 Other Application Example Circuits

When parasitic inductances are introduced by non-ideal PCB layout and long package leads (e.g. TO-220 and TO-247 type packages), there could be ringing in the gate-source drive voltage of the power transistor during high di/dt and dv/dt switching. If the ringing is over the threshold voltage, there is the risk of unintended turn-on and even shoot-through. Applying a negative bias on the gate drive is a popular way to keep such ringing below the threshold. Below are a few examples of implementing negative gate drive bias.

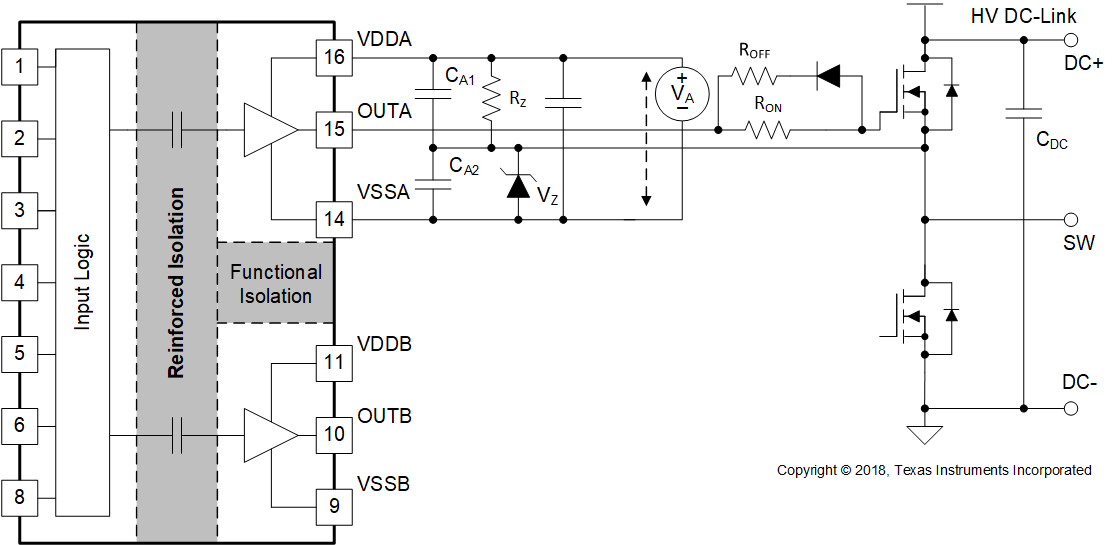

Instead of using two separate power for generating positive and negative drive voltage Figure 8-2 shows the example with negative bias turn-off on the channel-A driver using a Zener diode on the isolated power supply output stage. The negative bias is set by the Zener diode voltage. If the isolated power supply, VA, is equal to 19 V, the turn-off voltage will be –3.9 V and turn-on voltage will be 19 V -– 3.9 V ≈ 15 V. The channel-B driver circuit is the same as channel-A, therefore, this configuration needs only one power supply for each driver channel, and there will be steady state power consumption from RZ.

Figure 8-2 Negative

Bias with Zener Diode on Iso-Bias Power Supply Output

Figure 8-2 Negative

Bias with Zener Diode on Iso-Bias Power Supply OutputFigure 8-3 shows another example which uses bootstrap to provide power for the channel A, this solution doesn't have negative rail voltage, it is only suitable for circuits with less ringing or the power device has high threshold voltage.

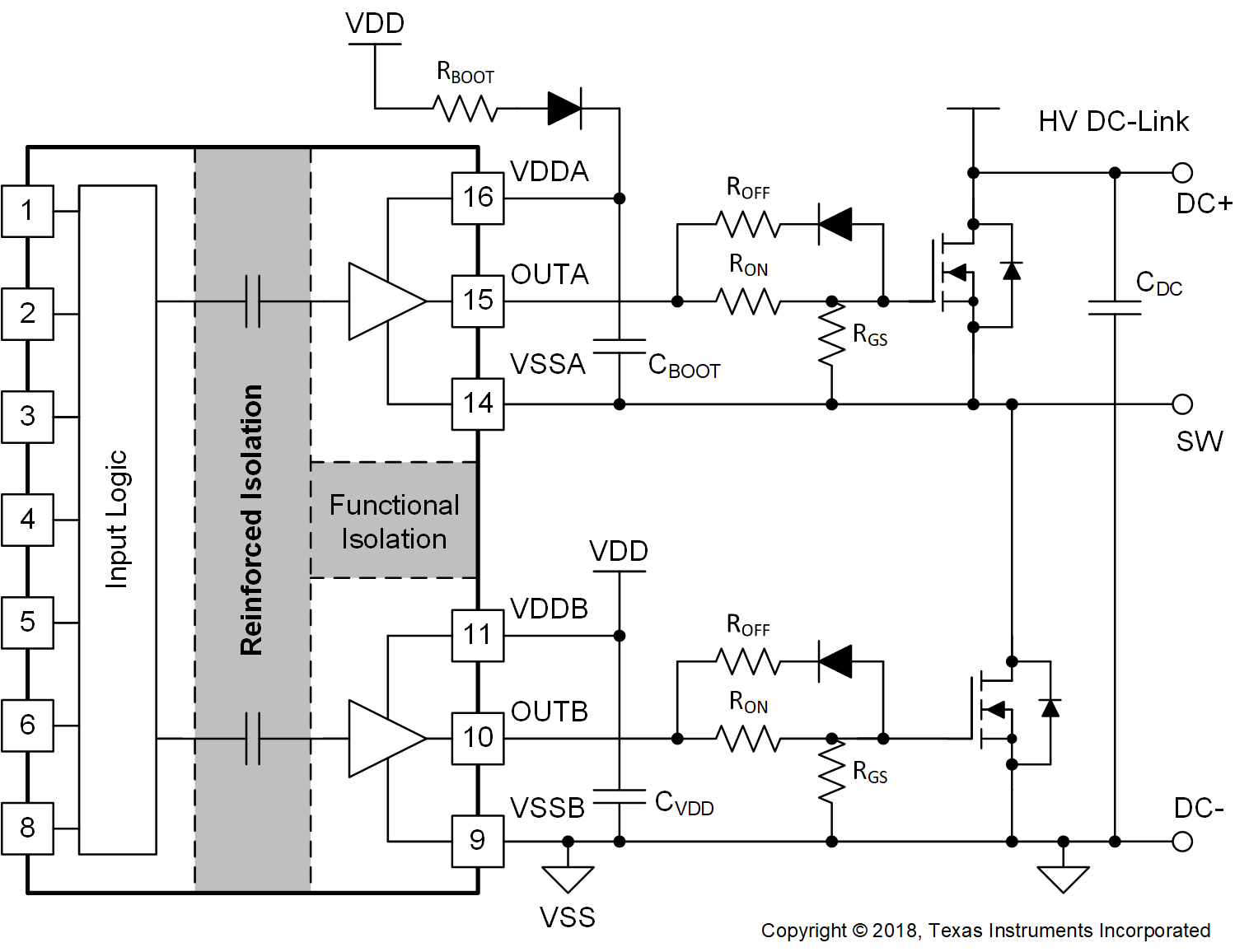

Figure 8-3 Bootstrap

Power Supply for the High Side Device

Figure 8-3 Bootstrap

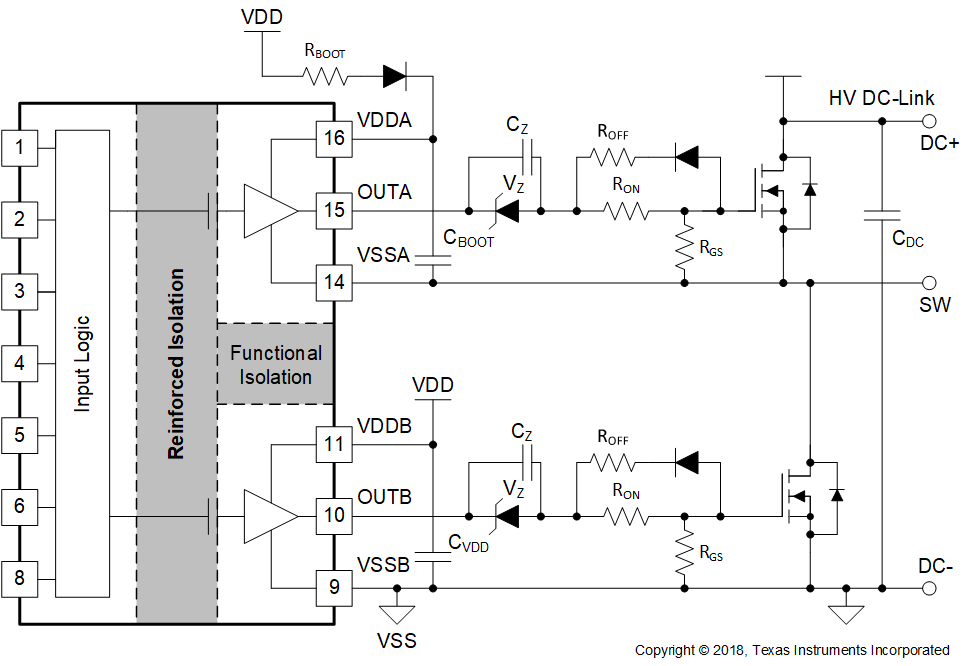

Power Supply for the High Side DeviceThe last example, shown in Figure 8-4, is a single power supply configuration and generates negative bias through a Zener diode in the gate drive loop. The benefit of this solution is that it only uses one power supply and the bootstrap power supply can be used for the high side drive. This design requires the least cost and design effort among the three solutions. However, this solution has limitations:

- The negative gate drive bias is not only determined by the Zener diode, but also by the duty cycle, which means the negative bias voltage will change when the duty cycle changes. Therefore, converters with a fixed duty cycle (~50%) such as variable frequency resonant convertors or phase shift convertors which favor this solution.

- The high side VDDA-VSSA must maintain enough voltage to stay in the recommended power supply range, which means the low side switch must turn-on or have free-wheeling current on the body (or anti-parallel) diode for a certain period during each switching cycle to refresh the bootstrap capacitor. Therefore, a 100% duty cycle for the high side is not possible unless there is a dedicated power supply for the high side, like in the other two example circuits.

Figure 8-4 Negative

Bias with Single Power Supply and Zener Diode in Gate Drive Path

Figure 8-4 Negative

Bias with Single Power Supply and Zener Diode in Gate Drive Path