SLUSDC0D October 2018 – November 2024 UCC21530

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Pin Configuration and Functions

-

5 Specifications

- 5.1 Absolute Maximum Ratings

- 5.2 ESD Ratings

- 5.3 Recommended Operating Conditions

- 5.4 Thermal Information

- 5.5 Power Ratings

- 5.6 Insulation Specifications

- 5.7 Safety Limiting Values

- 5.8 Electrical Characteristics

- 5.9 Timing Requirements

- 5.10 Switching Characteristics

- 5.11 Insulation Characteristics Curves

- 5.12 Typical Characteristics

- 6 Parameter Measurement Information

- 7 Detailed Description

-

8 Application and Implementation

- 8.1 Application Information

- 8.2

Typical Application

- 8.2.1 Design Requirements

- 8.2.2 Detailed Design Procedure

- 8.2.3 Application Curves

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Revision History

- 13Mechanical, Packaging, and Orderable Information

Package Options

Refer to the PDF data sheet for device specific package drawings

Mechanical Data (Package|Pins)

- DWK|14

Thermal pad, mechanical data (Package|Pins)

Orderable Information

3 Description

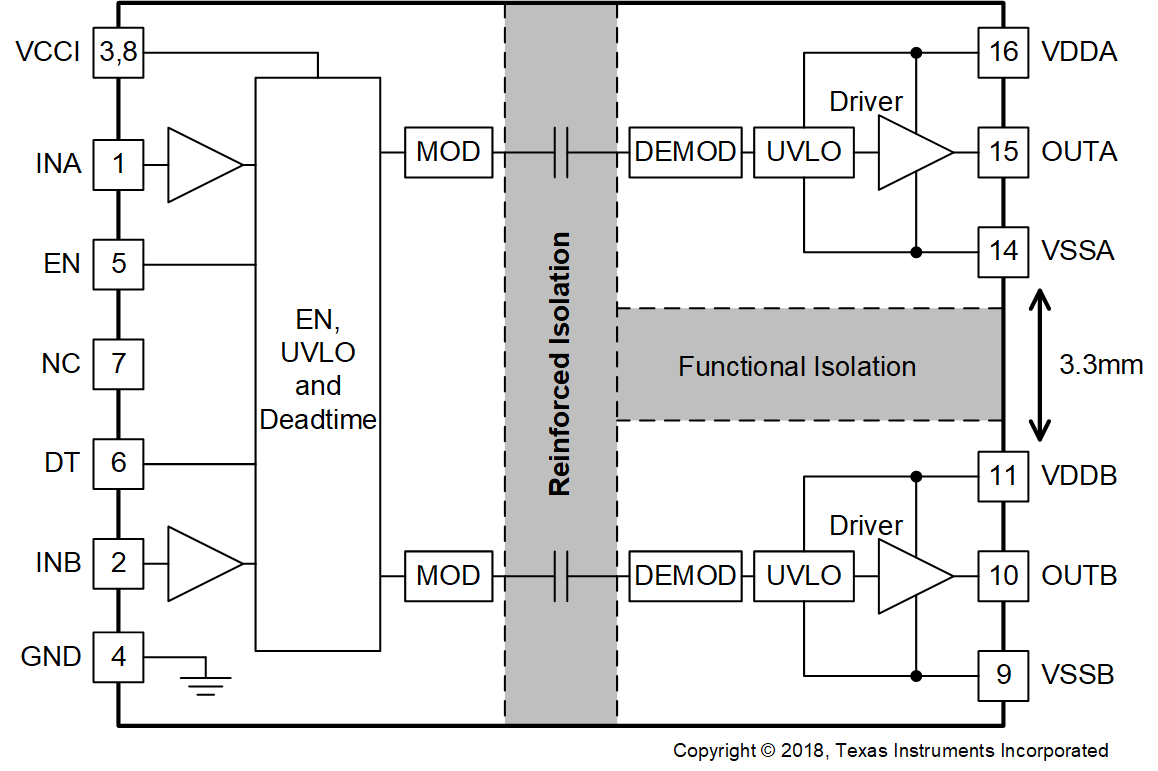

The UCC21530 is an isolated dual-channel gate driver with 4A source and 6A sink peak current. It is designed to drive IGBTs, Si MOSFETs, and SiC MOSFETs up to 5MHz.

The input side is isolated from the two output drivers by a 5.7kVRMS reinforced isolation barrier, with a minimum of 125V/ns common-mode transient immunity (CMTI). Internal functional isolation between the two secondary-side drivers allows a working voltage of up to 1850V.

This device can be configured as two low-side drivers, two high-side drivers, or a half-bridge driver with programmable dead time (DT). The EN pin pulled low shuts down both outputs simultaneously and allows for normal operation when left open or pulled high. As a fail-safe measure, primary-side logic failures force both outputs low.

The device accepts VDD supply voltages up to 25V. A wide input VCCI range from 3V to 18V makes the driver suitable for interfacing with both analog and digital controllers. All the supply voltage pins have under voltage lock-out (UVLO) protection.

| PART NUMBER | PACKAGE(1) | BODY SIZE (NOM) |

|---|---|---|

| UCC21530 | DWK (SOIC 14) | 10.30mm × 7.50mm |

Functional Block Diagram

Functional Block Diagram