-

LM61 2.7-V, SOT-23 or TO-92 Temperature Sensor

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

- IMPORTANT NOTICE

LM61 2.7-V, SOT-23 or TO-92 Temperature Sensor

1 Features

- Calibrated Linear Scale Factor of 10 mV/°C

- Rated for Full Temperature Range (–30° to 100°C)

- Suitable for Remote Applications

- UL Recognized Component

- ±2°C or ±3°C Accuracy at 25°C (Maximum)

- ±3°C Accuracy for –25°C to 85°C (Maximum)

- ±4°C Accuracy for –30°C to 100°C (Maximum)

- 10 mV/°C Temperature Slope (Maximum)

- 2.7-V to 10-V Power Supply Voltage Range

- 125-µA Current Drain at 25°C (Maximum)

- ±0.8°C Nonlinearity (Maximum)

- 800-Ω Output Impedance (Maximum)

2 Applications

- Cellular Phones

- Computers

- Power Supply Modules

- Battery Management

- FAX Machines

- Printers

- HVAC

- Disk Drives

- Appliances

3 Description

The LM61 device is a precision, integrated-circuit temperature sensor that can sense a –30°C to 100°C temperature range while operating from a single 2.7‑V supply. The output voltage of the LM61 is linearly proportional to temperature (10 mV/°C) and has a DC offset of 600 mV. The offset allows reading negative temperatures without the need for a negative supply. The nominal output voltage of the LM61 ranges from 300 mV to 1600 mV for a –30°C to 100°C temperature range. The LM61 is calibrated to provide accuracies of ±2°C at room temperature and ±3°C over the full –25°C to 85°C temperature range.

The linear output of the LM61, 600-mV offset, and factory calibration simplify external circuitry required in a single supply environment where reading negative temperatures is required. Because the quiescent current is less than 125 µA, self-heating is limited to a very low 0.2°C in still air. Shutdown capability for the LM61 is intrinsic because its inherent low power consumption allows it to be powered directly from the output of many logic gates.

Device Information(1)

| PART NUMBER | PACKAGE | BODY SIZE (NOM) |

|---|---|---|

| LM61 | SOT-23 (3) | 1.30 mm × 2.92 mm |

| TO-92 (3) | 4.30 mm × 4.30 mm |

- For all available packages, see the orderable addendum at the end of the data sheet.

Typical Application

Key Specifications

| VALUE | |

|---|---|

| Accuracy at 25°C | ±2°C or ±3°C |

| Accuracy for –25°C to 85°C | ±3°C |

| Accuracy for –30°C to 100°C | ±4°C |

| Temperature slope | 10 mV/°C |

| Power supply voltage | 2.7 V to 10 V |

| Current drain at 25°C | 125 µA |

| Nonlinearity | ±0.8°C |

| Output impedance | 800 Ω |

4 Revision History

Changes from I Revision (February 2013) to J Revision

- Added Device Information table, Device Comparison Table, Pin Configuration and Functions section, Specifications section, ESD Ratings table, Detailed Description section, Application and Implementation section, Power Supply Recommendations section, Layout section, Device and Documentation Support section, and Mechanical, Packaging, and Orderable Information sectionGo

- Added Thermal Information tableGo

- Changed RθJA values for DBZ (SOT-23) From: 450°C/W To: 286.3°C/W and for LP (TO-92) From: 180°C/W To: 162.2°C/WGo

Changes from H Revision (February 2013) to I Revision

- Changed layout of National Semiconductor Data Sheet to TI formatGo

5 Pin Configuration and Functions

Pin Functions

| PIN | TYPE | DESCRIPTION | |

|---|---|---|---|

| NAME | NO. | ||

| +VS | 1 | Power | Positive power supply pin. |

| VOUT | 2 | Output | Temperature sensor analog output. |

| GND | 3 | Ground | Device ground pin, connected to power supply negative terminal. |

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)(1)| MIN | MAX | UNIT | |

|---|---|---|---|

| Supply voltage | 12 | –0.2 | V |

| Output voltage | (+VS + 0.6) | –0.6 | V |

| Output current | 10 | mA | |

| Input current at any pin(2) | 5 | mA | |

| Maximum junction temperature, TJ | 125 | °C | |

| Storage temperature, Tstg | –65 | 150 | °C |

6.2 ESD Ratings

| VALUE | UNIT | |||

|---|---|---|---|---|

| V(ESD) | Electrostatic discharge | Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001(1)(2) | ±2500 | V |

| Machine Model (MM)(3) | ±250 | |||

6.3 Recommended Operating Conditions

| MIN | MAX | UNIT | |||

|---|---|---|---|---|---|

| +VS | Supply voltage | 2 | 10 | V | |

| T | Operating temperature | LM61C | –30 | 100 | °C |

| LM61B | –25 | 85 | |||

6.4 Thermal Information

| THERMAL METRIC(1) | LM61 | UNIT | ||

|---|---|---|---|---|

| DBZ (SOT-23) | LP (TO-92) | |||

| 3 PINS | 3 PINS | |||

| RθJA | Junction-to-ambient thermal resistance(2) | 286.3 | 162.2 | °C/W |

| RθJC(top) | Junction-to-case (top) thermal resistance | 96 | 85 | °C/W |

| RθJB | Junction-to-board thermal resistance | 57.1 | — | °C/W |

| ψJT | Junction-to-top characterization parameter | 5.3 | 29.2 | °C/W |

| ψJB | Junction-to-board characterization parameter | 55.8 | 141.4 | °C/W |

6.5 Electrical Characteristics

+VS = 3 V (DC)(1)(2)| PARAMETER | TEST CONDITIONS | MIN(3) | TYP(4) | MAX(3) | UNIT | |

|---|---|---|---|---|---|---|

| Accuracy(5) | TA = 25°C | LM61B | –2 | 2 | °C | |

| LM61C | –3 | 3 | ||||

| LM61B | –3 | 3 | ||||

| LM61C | –4 | 4 | ||||

| Output voltage at 0°C | 600 | mV | ||||

| Nonlinearity(6) | LM61B | –0.6 | 0.6 | °C | ||

| LM61C | –0.8 | 0.8 | ||||

| Sensor gain (average slope) | LM61B | 9.7 | 10 | 10.3 | mV/°C | |

| LM61C | 9.6 | 10 | 10.4 | |||

| Output impedance | +VS = 3 V to 10 V | 0.8 | kΩ | |||

| TA = –30°C to 85°C, +VS = 2.7 V | 2.3 | |||||

| TA = 85°C to 100°C, +VS = 2.7 V | 5 | |||||

| Line regulation(7) | +VS = 3 V to 10 V | –0.7 | 0.7 | mV/V | ||

| +VS = 2.7 V to 3.3 V | –5.7 | 5.7 | mV | |||

| Quiescent current | +VS = 2.7 V to 10 V | TA = 25°C | 82 | 125 | µA | |

| 155 | ||||||

| Change of quiescent current | +VS = 2.7 V to 10 V | ±5 | µA | |||

| Temperature coefficient of quiescent current | 0.2 | µA/°C | ||||

| Long term stability(8) | TJ = TMAX = 100°C, for 1000 hours | ±0.2 | °C | |||

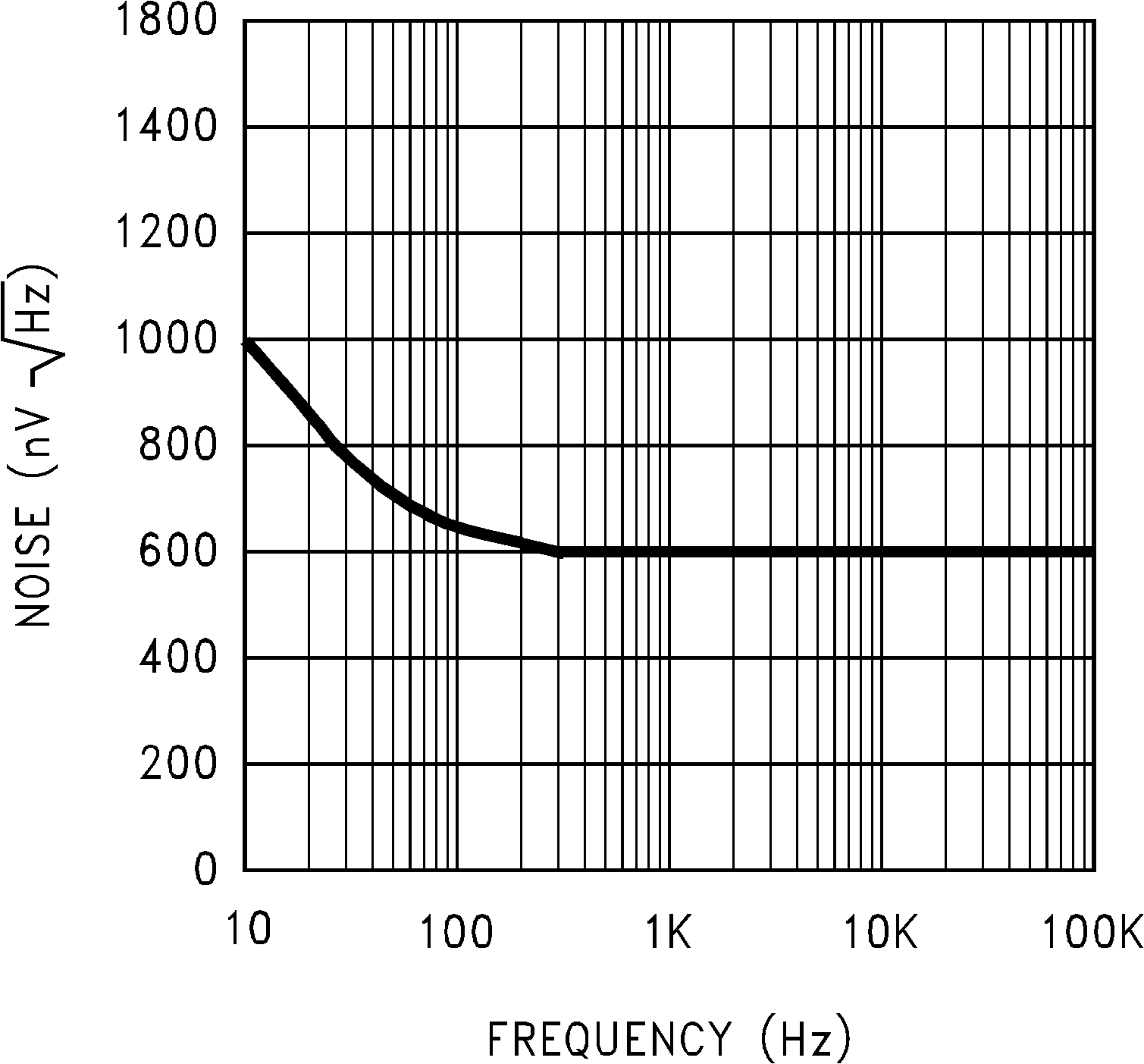

6.6 Typical Characteristics

The LM61 in the SOT-23 package mounted to a printed-circuit board as shown in Figure 18 was used to generate the following thermal curves.

with Heat Sink

7 Detailed Description

7.1 Overview

The LM61 is a precision integrated-circuit temperature sensor that can sense a –30°C to 100°C temperature range using a single positive supply. The output voltage of the LM61 has a positive temperature slope of

10 mV/°C. A 600-mV offset is included, enabling negative temperature sensing when biased by a single supply. The temperature-sensing element is comprised of a delta-VBE architecture. The temperature-sensing element is then buffered by an amplifier and provided to the VOUT pin. The amplifier has a simple class A output stage as shown in Functional Block Diagram.

7.2 Functional Block Diagram

7.3 Feature Description

7.3.1 LM61 Transfer Function

The LM61 follows a simple linear transfer function to achieve the accuracy as listed in Electrical Characteristics. Use Equation 1 to calculate the value of VO.

where

- T is the temperature in °C

- VO is the LM61 output voltage

7.4 Device Functional Modes

The only functional mode of the LM61 device is an analog output directly proportional to temperature.

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

The LM61 has a wide supply range and a 10-mV/°C output slope with a 600-mV DC. Therefore, it can be easily applied in many temperature-sensing applications where a single supply is required for positive and negative temperatures.

8.2 Typical Applications

8.2.1 Typical Temperature Sensing Circuit

8.2.1.1 Design Requirements

For this design example, use the parameters listed in Table 1 as the input parameters.

Table 1. Design Parameters

| PARAMETER | VALUE |

|---|---|

| Power supply voltage | 2.7 V to 3.3 V |

| Accuracy at 25°C | ±2°C (maximum) |

| Accuracy over –25°C to 85°C | ±3°C (maximum) |

| Temperature slope | 10 mV/°C |

8.2.1.2 Detailed Design Procedure

The LM61 is a simple temperature sensor that provides an analog output. Therefore, design requirements related to layout outweigh other requirements in importance. See Layout for more information.

8.2.1.2.1 Capacitive Loads

The LM61 handles capacitive loading well. Without any special precautions, the LM61 can drive any capacitive load as shown in Figure 12. Over the specified temperature range the LM61 has a maximum output impedance of 5 kΩ. In an extremely noisy environment it may be necessary to add some filtering to minimize noise pickup. It is recommended that 0.1-µF capacitor be added between +VS and GND to bypass the power-supply voltage, as shown in Figure 13. In a noisy environment it may be necessary to add a capacitor from VOUT to ground. A 1-µF output capacitor with the 5-kΩ maximum output impedance forms a 32-Hz lowpass filter. Because the thermal time constant of the LM61 is much slower than the 5-ms time constant formed by the RC, the overall response time of the LM61 is not significantly affected. For much larger capacitors this additional time lag increases the overall response time of the LM61.

Figure 12. LM61 No Decoupling Required for Capacitive Load

Figure 12. LM61 No Decoupling Required for Capacitive Load

Figure 13. LM61 with Filter for Noisy Environments

Figure 13. LM61 with Filter for Noisy Environments

8.2.1.3 Application Curve

Figure 14. Accuracy vs Temperature

Figure 14. Accuracy vs Temperature

8.2.2 Other Application Circuits

Figure 15 shows an application circuit example using the LM61 device. Customers must fully validate and test any circuit before implementing a design based on an example in this section. Unless otherwise noted, the design procedures in Typical Temperature Sensing Circuit are applicable.

Figure 15. Centigrade Thermostat

Figure 15. Centigrade Thermostat

Figure 16. Conserving Power Dissipation with Shutdown

Figure 16. Conserving Power Dissipation with Shutdown

9 Power Supply Recommendations

In an extremely noisy environment, it may be necessary to add filtering to minimize noise pickup. TI recommends a 0.1-µF capacitor be added between +VS to GND to bypass the power-supply voltage, as shown in Figure 13.

10 Layout

10.1 Layout Guidelines

10.1.1 Mounting

The LM61 can be applied easily in the same way as other integrated-circuit temperature sensors. It can be glued or cemented to a surface. The temperature that the LM61 senses is within about 0.2°C of the surface temperature that LM61's leads are attached to.

This presumes that the ambient air temperature is almost the same as the surface temperature; if the air temperature is much higher or lower than the surface temperature, the actual temperature measured would be at an intermediate temperature between the surface temperature and the air temperatures.

To ensure good thermal conductivity the backside of the LM61 die is directly attached to the GND pin. The lands and traces to the LM61 are part of the printed-circuit board, which is the object whose temperature is being measured.

Alternatively, the LM61 can be mounted inside a sealed-end metal tube, and can then be dipped into a bath or screwed into a threaded hole in a tank. As with any IC, the LM61 and accompanying wiring and circuits must be kept insulated and dry, to avoid leakage and corrosion. This is especially true if the circuit may operate at cold temperatures where condensation can occur. Printed-circuit coatings and varnishes such as Humiseal and epoxy paints or dips are often used to ensure that moisture cannot corrode the device or connections.

10.2 Layout Examples

Figure 17. Recommended Solder Pads for SOT-23 Package

Figure 17. Recommended Solder Pads for SOT-23 Package

Figure 19. PCB Layout

Figure 19. PCB Layout

10.3 Thermal Considerations

The junction-to-ambient thermal resistance is the parameter used to calculate the rise of a device junction temperature due to its power dissipation. For the LM61, Equation 2 is used to calculate the rise in the die temperature.

where

- IQ is the quiescent current

- ILis the load current on the output

Table 2 summarizes the rise in die temperature of the LM61 without any loading with a 3.3-V supply, and the thermal resistance for different conditions.

Table 2. Temperature Rise of LM61 Due to Self-Heating and Thermal Resistance (RθJA)

| RθJA (°C/W) | TJ – TA (°C) | |||

|---|---|---|---|---|

| SOT-23 | No heat sink(1) | Still air | 450 | 0.26 |

| Moving air | — | — | ||

| Small heat fin(2) | Still air | 260 | 0.13 | |

| Moving air | 180 | 0.09 | ||

| TO-92 | No heat sink(1) | Still air | 180 | 0.09 |

| Moving air | 90 | 0.05 | ||

| Small heat fin(3) | Still air | 140 | 0.07 | |

| Moving air | 70 | 0.03 | ||

Table 3. Temperature and Typical VO Values

| TEMPERATURE | VO(TYPICAL) |

|---|---|

| 100°C | 1600 mV |

| 85°C | 1450 mV |

| 25°C | 850 mV |

| 0°C | 600 mV |

| –25°C | 350 mV |

| –30°C | 300 mV |

11 Device and Documentation Support

11.1 Related Documentation

For related documentation see the following:

11.2 Receiving Notification of Documentation Updates

To receive notification of documentation updates, navigate to the device product folder on ti.com. In the upper right corner, click on Alert me to register and receive a weekly digest of any product information that has changed. For change details, review the revision history included in any revised document.

11.3 Community Resources

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of Use.

-

TI E2E™ Online Community TI's Engineer-to-Engineer (E2E) Community. Created to foster collaboration among engineers. At e2e.ti.com, you can ask questions, share knowledge, explore ideas and help solve problems with fellow engineers.

-

Design Support TI's Design Support Quickly find helpful E2E forums along with design support tools and contact information for technical support.

11.4 Trademarks

E2E is a trademark of Texas Instruments.

All other trademarks are the property of their respective owners.

11.5 Electrostatic Discharge Caution

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

11.6 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 Mechanical, Packaging, and Orderable Information

The following pages include mechanical, packaging, and orderable information. This information is the most current data available for the designated devices. This data is subject to change without notice and revision of this document. For browser-based versions of this data sheet, refer to the left-hand navigation.

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and complete. All semiconductor products (also referred to herein as "components") are sold subject to TI's terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI's terms and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily performed.

TI assumes no liability for applications assistance or the design of Buyers' products. Buyers are responsible for their products and applications using TI components. To minimize the risks associated with Buyers' products and applications, Buyers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI's goal is to help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or "enhanced plastic" are designed and intended for use in military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products

- Audio: www.ti.com/audio

- Amplifiers: amplifier.ti.com

- Data Converters: dataconverter.ti.com

- DLP® Products: www.dlp.com

- DSP: dsp.ti.com

- Clocks and Timers: www.ti.com/clocks

- Interface: interface.ti.com

- Logic: logic.ti.com

- Power Mgmt: power.ti.com

- Microcontrollers: microcontroller.ti.com

- RFID: www.ti.rfid.com

- OMAP Application Processors: www.ti.com/omap

- Wireless Connectivity: www.ti.com/wirelessconnectivity

Applications

- Automotive and Transportation: www.ti.com/automotive

- Communications and Telecom: www.ti.com/communications

- Computers and Peripherals: www.ti.com/computers

- Consumer Electronics: www.ti.com/consumer-apps

- Energy and Lighting: www.ti.com/energy

- Industrial: www.ti.com/industrial

- Medical: www.ti.com/medical

- Security: www.ti.com/security

- Space, Avionics and Defense: www.ti.com/space-avionics-defense

- Video & Imaging: www.ti.com/video

TI E2E Community : e2e.ti.com

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright© 2016, Texas Instruments Incorporated