SLVSBH2C June 2012 – December 2015 DRV8823-Q1

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

パッケージ・オプション

メカニカル・データ(パッケージ|ピン)

- DCA|48

サーマルパッド・メカニカル・データ

- DCA|48

発注情報

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

The DRV8823-Q1 can be used to drive two bipolar stepper motors.

8.2 Typical Application

Figure 14. Typical Application Schematic

Figure 14. Typical Application Schematic

8.2.1 Design Requirements

Table 5 lists the design requirements for this design example.

Table 5. Design Parameters

| DESIGN PARAMETER | REFERENCE | EXAMPLE VALUE |

|---|---|---|

| Supply voltage | VM | 24 V |

| Motor winding resistance | RL | 7.4 Ω/phase |

| Motor full-step angle | θstep | 1.8°/step |

| Target microstepping angle | nM | 1/8 step |

| Target motor speed | V | 120 rpm |

| Target full-scale current | IFS | 1 A |

8.2.2 Detailed Design Procedure

8.2.2.1 Motor Voltage

The appropriate motor voltage will depend on the ratings of the motor selected and the desired torque. A higher voltage shortens the current rise time in the coils of the stepper motor allowing a greater average torque. Using a higher voltage also allows the motor to operate at a faster speed than a lower voltage.

8.2.2.2 Drive Current

The current path running to the motor starts from the supply VM, then goes through the high-side sourcing NMOS power FET, moves through the inductive winding load of the motor, then through the low-side sinking NMOS power FET, and finally going through the external sense resistor. Power dissipation losses in both NMOS power FETs inside of the DRV8823-Q1 are shown in the following equation.

The DRV8823-Q1 has been measured to be capable of 1.5-A continuous current with the HTSSOP package at 25°C on standard FR-4 PCBs. The max continuous current will vary based on PCB design and the ambient temperature.

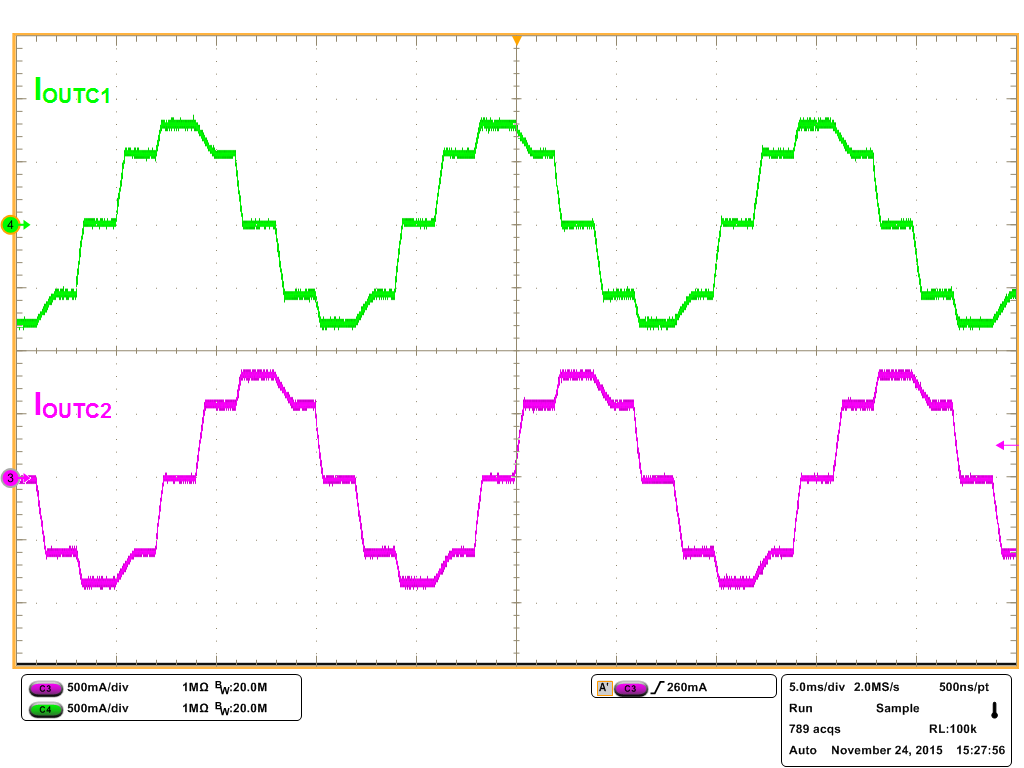

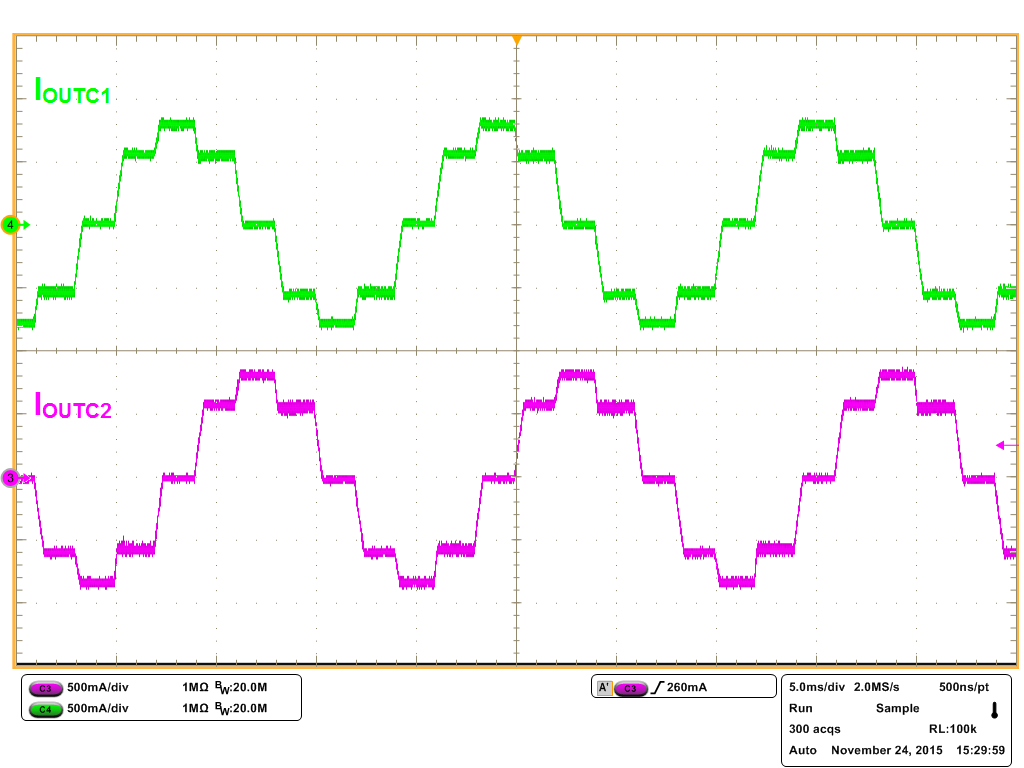

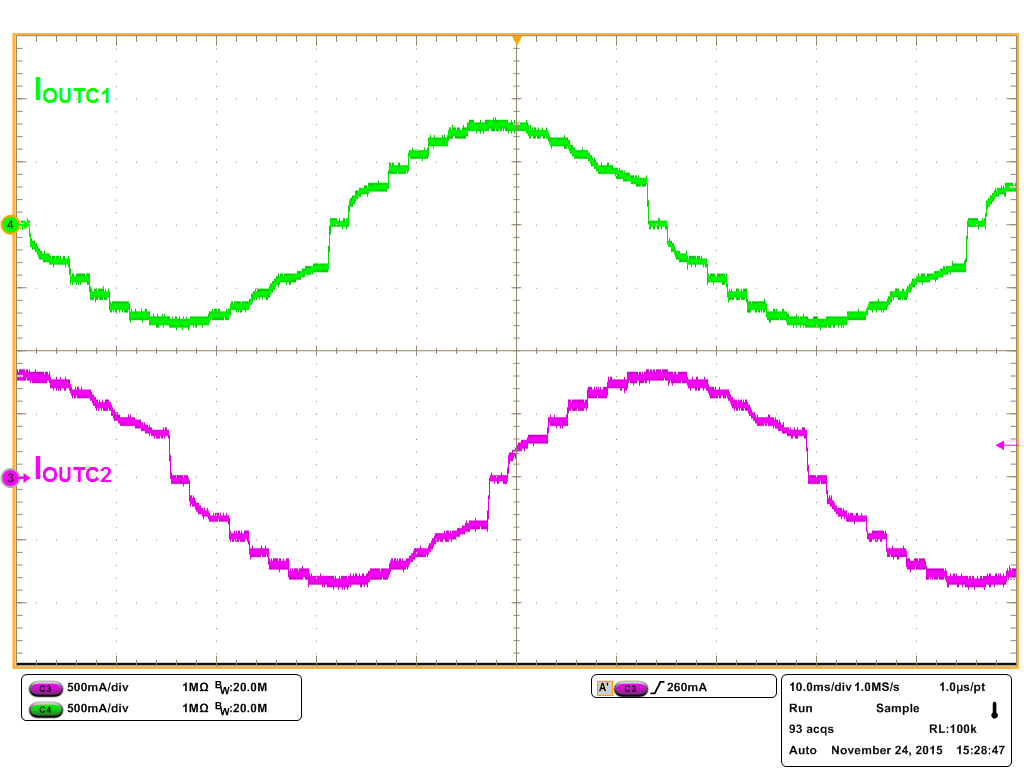

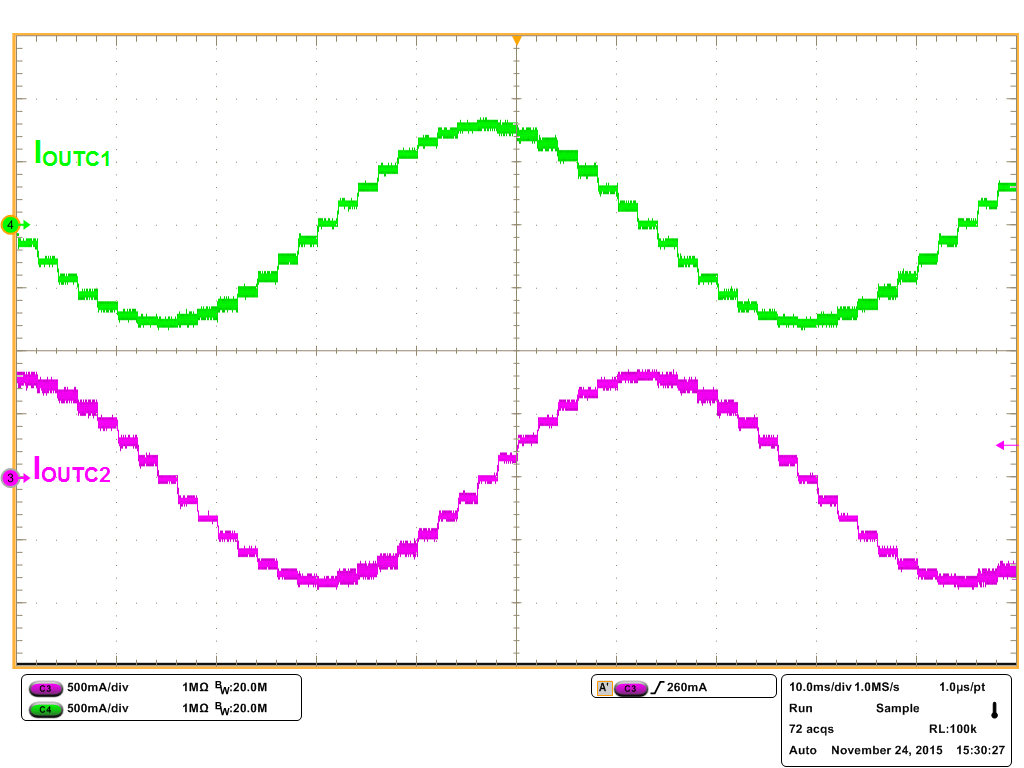

8.2.3 Application Curves

Figure 15. ½ Step Microstepping With Slow Decay

Figure 15. ½ Step Microstepping With Slow Decay

Figure 17. ½ Step Microstepping With Mixed Decay

Figure 17. ½ Step Microstepping With Mixed Decay

Figure 16. 1/8 Step Microstepping With Slow Decay

Figure 16. 1/8 Step Microstepping With Slow Decay

Figure 18. 1/8 Step Microstepping With Mixed Decay

Figure 18. 1/8 Step Microstepping With Mixed Decay