-

OPAx316-Q1 10MHz、レール・ツー・レール入出力、低電圧、1.8V CMOSオペアンプ JAJSCY2A November 2016 – January 2017 OPA2316-Q1 , OPA316-Q1 , OPA4316-Q1

PRODUCTION DATA.

-

OPAx316-Q1 10MHz、レール・ツー・レール入出力、低電圧、1.8V CMOSオペアンプ

- 1 特長

- 2 アプリケーション

- 3 概要

- 4 改訂履歴

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11デバイスおよびドキュメントのサポート

- 12メカニカル、パッケージ、および注文情報

- 重要なお知らせ

OPAx316-Q1 10MHz、レール・ツー・レール入出力、低電圧、1.8V CMOSオペアンプ

1 特長

2 アプリケーション

- 車載用アプリケーション

- ADAS (先進運転支援システム)

- 車体エレクトロニクスおよび照明

- 電流検出

- バッテリ管理システム

3 概要

OPAx316-Q1ファミリのシングルおよびデュアル・オペアンプは、新世代の汎用、低消費電力のオペアンプを代表する製品です。レール・ツー・レールの入力および出力、低い静止電流(標準値400μA/ch)、10MHzの広い帯域幅、非常に低いノイズ(1kHzにおいて11nV/√Hz)という特長から、このファミリは優れた速度/電力比を必要とする回路に適しています。

入力バイアス電流が小さいため、これらのオペアンプはメガオームのソース・インピーダンスを持つアプリケーションに対応できます。OPAx316-Q1は入力バイアス電流が小さいため、電流ノイズもごく小さく、高インピーダンスのセンサ・インターフェイスに魅力的な選択肢です。

OPAx316-Q1は堅牢に設計されており、ユニティ・ゲイン安定、RFIおよびEMI除去フィルタの内蔵、オーバードライブ状態で位相反転が発生しない、高い静電放電(ESD)保護(4kV HBM)という特長から、回路設計者が簡単に使用できます。

これらのデバイスは、最小1.8V (±0.9V)、最大5.5V (±2.75V)の低電圧での動作に最適化されています。この車載グレードの低電圧CMOSオペアンプが追加されたことにより、広い帯域幅、低ノイズ、低消費電力で、広範なアプリケーションの要求を満たす製品ファミリとなりました。

製品情報(1)

| 型番 | パッケージ | 本体サイズ(typ) |

|---|---|---|

| OPA316-Q1 | SOT-23 (5) | 1.60mm×2.90mm |

| OPA2316-Q1 | VSSOP (8) | 3.00mm×3.00mm |

| OPA4316-Q1 | TSSOP (14) | 4.40mm×5.00mm |

- 利用可能なすべてのパッケージについては、このデータシートの末尾にある注文情報を参照してください。

シングル・ポールのローパス・フィルタ

10MHz帯域幅での低い消費電流(400µA/ch)

4 改訂履歴

Changes from * Revision (November 2016) to A Revision

- Changed CDM分類レベルをC6からGo

- Deleted 「製品情報」表からOPA2316S-Q1のパッケージおよび本体サイズの情報をGo

- Deleted 「製品情報」表、「熱に関する情報」表、ピン配置図からSC70 (5) (OPA316-Q1)、DFN (8)、MSOP (8)、SOIC (8) (OPA2316-Q1)、SOIC (14)パッケージ(OPA4316-Q1)をGo

- Deleted OPA2316S-Q1 pin diagram and Pin Functions table in Pin Configurations and Functions section Go

- Deleted D (SOIC) package from OPA4316-Q1 pin diagram in Pin Configurations and Functions section Go

- Changed CDM rating from ±1500 V to ±750 VGo

- Deleted OPA2316S-Q1 device thermal information in the Thermal Information table Go

- Added thermal information for OPA4316-Q1 deviceGo

- Deleted 「ドキュメントのサポート」セクションでTIドキュメント参照のフォーマットに含まれる括弧内の文書番号Go

5 Pin Configuration and Functions

Pin Functions: OPA316-Q1

| PIN | I/O | DESCRIPTION | |

|---|---|---|---|

| NAME | NO. | ||

| –IN | 4 | I | Inverting input |

| +IN | 3 | I | Noninverting input |

| V– | 2 | — | Negative supply or ground (for single-supply operation). |

| V+ | 5 | — | Positive supply |

| OUT | 1 | O | Output |

Pin Functions: OPA2316-Q1

| PIN | I/O | DESCRIPTION | |

|---|---|---|---|

| NAME | NO. | ||

| –IN A | 2 | I | Inverting input, channel A |

| +IN A | 3 | I | Noninverting input, channel A |

| –IN B | 6 | I | Inverting input, channel B |

| +IN B | 5 | I | Noninverting input, channel B |

| OUT A | 1 | O | Output, channel A |

| OUT B | 7 | O | Output, channel B |

| V– | 4 | — | Negative supply or ground (for single-supply operation). |

| V+ | 8 | — | Positive supply |

Pin Functions: OPA4316-Q1

| PIN | I/O | DESCRIPTION | |

|---|---|---|---|

| NAME | NO. | ||

| –IN A | 2 | I | Inverting input, channel A |

| +IN A | 3 | I | Noninverting input, channel A |

| –IN B | 6 | I | Inverting input, channel B |

| +IN B | 5 | I | Noninverting input, channel B |

| –IN C | 9 | I | Inverting input, channel C |

| +IN C | 10 | I | Noninverting input, channel C |

| –IN D | 13 | I | Inverting input, channel D |

| +IN D | 12 | I | Noninverting input, channel D |

| OUT A | 1 | O | Output, channel A |

| OUT B | 7 | O | Output, channel B |

| OUT C | 8 | O | Output, channel C |

| OUT D | 14 | O | Output, channel D |

| V– | 11 | — | Negative supply or ground (for single-supply operation) |

| V+ | 4 | — | Positive supply |

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature (unless otherwise noted)(1)| MIN | MAX | UNIT | |||

|---|---|---|---|---|---|

| Supply voltage | 7 | V | |||

| Signal input pins | Voltage(2) | Common-mode | (V–) – 0.5 | (V+) + 0.5 | V |

| Differential | (V+) – (V–) + 0.2 | V | |||

| Current(2) | –10 | 10 | mA | ||

| Output short-circuit(3) | Continuous | ||||

| TA | Operating temperature | –55 | 150 | °C | |

| TJ | Junction temperature | 150 | °C | ||

| Tstg | Storage temperature | –65 | 150 | °C | |

6.2 ESD Ratings

| VALUE | UNIT | |||

|---|---|---|---|---|

| V(ESD) | Electrostatic discharge | Human-body model (HBM), per AEC Q100-002(1) | ±4000 | V |

| Charged-device model (CDM), per AEC Q100-011 | ±750 | |||

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)| MIN | MAX | UNIT | |||

|---|---|---|---|---|---|

| VS | Supply voltage | 1.8 | 5.5 | V | |

| Specified temperature | –40 | 125 | °C | ||

6.4 Thermal Information: OPA316-Q1

| THERMAL METRIC(1) | OPA316-Q1 | UNIT | |

|---|---|---|---|

| DBV (SOT-23) | |||

| 5 PINS | |||

| RθJA | Junction-to-ambient thermal resistance(2) | 221.7 | °C/W |

| RθJC(top) | Junction-to-case(top) thermal resistance(3) | 144.7 | °C/W |

| RθJB | Junction-to-board thermal resistance(4) | 49.7 | °C/W |

| ψJT | Junction-to-top characterization parameter(5) | 26.1 | °C/W |

| ψJB | Junction-to-board characterization parameter(6) | 49 | °C/W |

| RθJC(bot) | Junction-to-case(bottom) thermal resistance(7) | N/A | °C/W |

6.5 Thermal Information: OPA2316-Q1

| THERMAL METRIC(1) | OPA2316-Q1 | UNIT | |

|---|---|---|---|

| DGK (VSSOP) | |||

| 8 PINS | |||

| RθJA | Junction-to-ambient thermal resistance(2) | 186.6 | °C/W |

| RθJC(top) | Junction-to-case(top) thermal resistance(3) | 78.8 | °C/W |

| RθJB | Junction-to-board thermal resistance(4) | 107.9 | °C/W |

| ψJT | Junction-to-top characterization parameter(5) | 15.5 | °C/W |

| ψJB | Junction-to-board characterization parameter(6) | 106.3 | °C/W |

| RθJC(bot) | Junction-to-case(bottom) thermal resistance(7) | N/A | °C/W |

6.6 Thermal Information: OPA4316-Q1

| THERMAL METRIC(1) | OPA4316-Q1 | UNIT | |

|---|---|---|---|

| PW (TSSOP) | |||

| 14 PINS | |||

| RθJA | Junction-to-ambient thermal resistance(2) | 117.2 | °C/W |

| RθJC(top) | Junction-to-case(top) thermal resistance(3) | 46.2 | °C/W |

| RθJB | Junction-to-board thermal resistance(4) | 58.9 | °C/W |

| ψJT | Junction-to-top characterization parameter(5) | 4.9 | °C/W |

| ψJB | Junction-to-board characterization parameter(6) | 58.3 | °C/W |

| RθJC(bot) | Junction-to-case(bottom) thermal resistance(2) | N/A | °C/W |

6.7 Electrical Characteristics

VS (total supply voltage) = (V+) – (V–) = 1.8 V to 5.5 V.at TA = 25°C, RL = 10 kΩ connected to VS / 2, VCM = VS / 2, and VOUT = VS / 2, unless otherwise noted

| PARAMETER | TEST CONDITIONS | MIN | TYP | MAX | UNIT | ||

|---|---|---|---|---|---|---|---|

| OFFSET VOLTAGE | |||||||

| VOS | Input offset voltage | VS = 5 V | ±0.5 | ±2.5 | mV | ||

| VS = 5 V, TA = –40°C to 125°C | ±3.5 | mV | |||||

| dVOS/dT | Drift | VS = 5 V, TA = –40°C to 125°C | ±2 | ±10 | μV/°C | ||

| PSRR | vs power supply | VS = 1.8 V – 5.5 V, VCM = (V–) | ±30 | ±150 | µV/V | ||

| VS = 1.8 V – 5.5 V, VCM = (V–), TA = –40°C to 125°C | ±250 | µV/V | |||||

| Channel separation, dc | At dc | 10 | µV/V | ||||

| INPUT VOLTAGE RANGE | |||||||

| VCM | Common-mode voltage | VS = 1.8 V to 2.5 V | (V–) – 0.2 | (V+) | V | ||

| VS = 2.5 V to 5.5 V | (V–) – 0.2 | (V+) + 0.2 | V | ||||

| CMRR | Common-mode rejection ratio | VS = 1.8 V, (V–) – 0.2 V < VCM < (V+) – 1.4 V, TA= –40°C to 125°C |

70 | 86 | dB | ||

| VS = 5.5 V, (V–) – 0.2 V < VCM < (V+) – 1.4 V, TA= –40°C to 125°C |

76 | 90 | dB | ||||

| VS = 1.8 V, VCM = –0.2 V to 1.8 V, TA= –40°C to 125°C |

57 | 72 | dB | ||||

| VS = 5.5 V, VCM = –0.2 V to 5.7 V, TA= –40°C to 125°C |

65 | 80 | dB | ||||

| INPUT BIAS CURRENT | |||||||

| IB | Input bias current | ±5 | ±15 | pA | |||

| TA= –40°C to 125°C | ±15 | nA | |||||

| IOS | Input offset current | ±2 | ±15 | pA | |||

| TA= –40°C to 125°C | ±8 | nA | |||||

| NOISE | |||||||

| En | Input voltage noise (peak-to-peak) | VS = 5 V, f = 0.1 Hz to 10 Hz | 3 | μVPP | |||

| en | Input voltage noise density | VS = 5 V, f = 1 kHz | 11 | nV/√Hz | |||

| in | Input current noise density | f = 1 kHz | 1.3 | fA/√Hz | |||

| INPUT IMPEDANCE | |||||||

| ZID | Differential | 2 || 2 | 1016Ω || pF | ||||

| ZIC | Common-mode | 2 || 4 | 1011Ω || pF | ||||

| OPEN-LOOP GAIN | |||||||

| AOL | Open-loop voltage gain | VS = 1.8 V, (V–) + 0.04 V < VO < (V+) – 0.04 V, RL = 10 kΩ |

94 | 100 | dB | ||

| VS = 5.5 V, (V–) + 0.05 V < VO < (V+) – 0.05 V, RL = 10 kΩ |

104 | 110 | dB | ||||

| VS = 1.8 V, (V–) + 0.1 V < VO < (V+) – 0.1 V, RL = 2 kΩ |

90 | 96 | dB | ||||

| VS = 5.5 V, (V–) + 0.15 V < VO < (V+) – 0.15 V, RL = 2 kΩ |

100 | 106 | dB | ||||

| VS = 5.5 V, (V–) + 0.05 V < VO < (V+) – 0.05 V, RL = 10 kΩ, TA= –40°C to 125°C |

86 | dB | |||||

| VS = 5.5 V, (V–) + 0.15 V < VO < (V+) – 0.15 V, RL = 2 kΩ, TA= –40°C to 125°C |

84 | dB | |||||

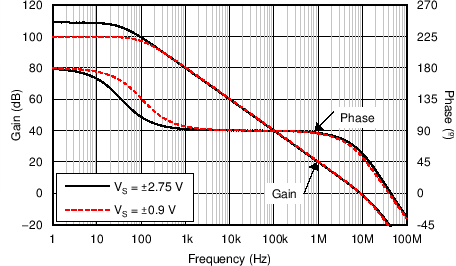

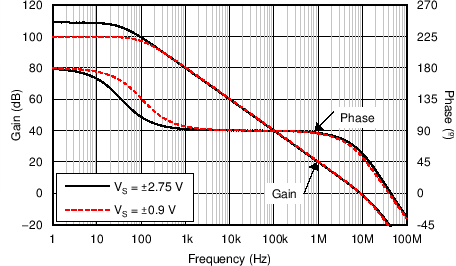

| FREQUENCY RESPONSE | |||||||

| GBP | Gain bandwidth product | VS = 5 V, G = 1 | 10 | MHz | |||

| φm | Phase margin | VS = 5 V, G = 1 | 60 | Degrees | |||

| SR | Slew rate | VS = 5 V, G = 1 | 6 | V/μs | |||

| tS | Settling time | To 0.1%, VS = 5 V, 2-V step , G = 1, CL = 100 pF | 1 | μs | |||

| To 0.01%, VS = 5 V, 2-V step , G = 1, CL = 100 pF | 1.66 | μs | |||||

| tOR | Overload recovery time | VS = 5 V, VIN × gain = VS | 0.3 | μs | |||

| THD + N | Total harmonic distortion + noise(1) | VS = 5 V, VO = 0.5 VRMS, G = 1 f = 1 kHz |

0.0008% | ||||

| OUTPUT | |||||||

| VO | Voltage output swing from supply rails | VS = 1.8 V, RL = 10 kΩ, TA= –40°C to 125°C | 15 | mV | |||

| VS = 5.5 V, RL = 10 kΩ, TA= –40°C to 125°C | 30 | mV | |||||

| VS = 1.8 V, RL = 2 kΩ, TA= –40°C to 125°C | 60 | mV | |||||

| VS = 5.5 V, RL = 2 kΩ, TA= –40°C to 125°C | 120 | mV | |||||

| ISC | Short-circuit current | VS = 5 V | ±50 | mA | |||

| ZO | Open-loop output impedance | VS = 5 V, f = 10 MHz | 250 | Ω | |||

| POWER SUPPLY | |||||||

| VS | Specified voltage | 1.8 | 5.5 | V | |||

| IQ | Quiescent current per amplifier | VS = 5 V, IO = 0 mA, TA= –40°C to 125°C | 400 | 500 | µA | ||

| Power-on time | VS = 0 V to 5.5 V | 200 | µs | ||||

6.8 Typical Characteristics

at TA = 25°C, VS = 5.5 V, RL = 10 kΩ connected to VS / 2, VCM = VS / 2, and VOUT = VS / 2, unless otherwise noted.

| Distribution taken from 12551 amplifiers | ||

| 9 typical units shown | ||

| V+ = 0.9 V to 2.75 V, V– = –0.9 V to –2.75 V, 9 typical units shown |

| RL = 10 kΩ | ||

| V+ = 2.75 V, V– = –2.75 V | ||

| Bandwidth = 80 kHz, VOUT = 0.5 VRMS | ||

| V+ = 2.75 V | G = +1 V/V | RL = 1 kΩ |

| V– = –2.75 V |

| V+ = 2.75 V | V– = –2.75 V | G = –10 V/V |

| V+ = 2.75 V | V– = –2.75 V | G = +1 V/V |

| CL = 100 pF | G = +1 V/V |

| PRF = –10 dBm | ||

Referred to Noninverting Input (EMIRR IN+) vs Frequency

| TA = –40°C to +125°C, Distribution taken from 70 amplifiers | ||

| V+ = 2.75 V, V– = –2.75 V, 9 typical units shown | ||

| VCM < (V+) – 1.4 V | ||

| RL = 2 kΩ | ||

(Referred to Input)

| ƒ = 1 kHz | ||

| ƒ = 1 kHz, Bandwidth = 80 kHz | ||

| V+ = 2.75 V | V– = –2.75 V | G = –1 V/V |

| V+ = 2.75 V | V– = –2.75 V | |

| V+ = 2.75 V | V– = –2.75 V | G = –10 V/V |

| V+ = 2.75 V | CL = 100 pF | G = +1 V/V |

| V– = –2.75 V |

| CL = 100 pF | G = +1 V/V |

Frequency and Supply Voltage

| V+ = 2.75 V, V– = –2.75 V | ||

7 Detailed Description

7.1 Overview

The OPAx316-Q1 is a family of low-power, rail-to-rail input and output operational amplifiers. These devices operate from 1.8 V to 5.5 V, are unity-gain stable, and are suitable for a wide range of general-purpose applications. The class AB output stage is capable of driving less than or equal to 10-kΩ loads connected to any point between V+ and ground. The input common-mode voltage range includes both rails and allows the OPAx316-Q1 series to be used in virtually any single-supply application. Rail-to-rail input and output swing significantly increases dynamic range, especially in low-supply applications, and makes them suitable for driving sampling analog-to-digital converters (ADCs).

The OPAx316-Q1 family features 10-MHz bandwidth and 6-V/μs slew rate with only 400-μA supply current per channel, providing good ac performance at very-low-power consumption. DC applications are well served with a very-low input noise voltage of 11 nV/√Hz at 1 kHz, low input bias current (5 pA), and a typical input offset voltage of 0.5-mV.

7.2 Functional Block Diagram

7.3 Feature Description

7.3.1 Operating Voltage

The OPAx316-Q1 operational amplifiers are fully specified and ensured for operation from 1.8 V to 5.5 V. In addition, many specifications apply from –40°C to +125°C. Parameters that vary significantly with operating voltages or temperature are illustrated in the Typical Characteristics graphs.

7.3.2 Rail-to-Rail Input

The input common-mode voltage range of the OPAx316-Q1 series extends 200 mV beyond the supply rails for supply voltages greater than 2.5 V. This performance is achieved with a complementary input stage: an N-channel input differential pair in parallel with a P-channel differential pair, as shown in the Functional Block Diagram. The N-channel pair is active for input voltages close to the positive rail, typically (V+) – 1.4 V to 200 mV above the positive supply, whereas the P-channel pair is active for inputs from 200 mV below the negative supply to approximately (V+) – 1.4 V. There is a small transition region, typically (V+) – 1.2 V to (V+) – 1 V, in which both pairs are on. This 200-mV transition region can vary up to 200 mV with process variation. Thus, the transition region (both stages on) can range from (V+) – 1.4 V to (V+) – 1.2 V on the low end, up to (V+) – 1 V to (V+) – 0.8 V on the high end. Within this transition region, PSRR, CMRR, offset voltage, offset drift, and THD can degrade compared to device operation outside this region.

7.3.3 Input and ESD Protection

The OPAx316-Q1 incorporates internal ESD protection circuits on all pins. In the case of input and output pins, this protection primarily consists of current-steering diodes connected between the input and power-supply pins. These ESD protection diodes provide in-circuit, input overdrive protection, as long as the current is limited to 10 mA, as stated in Absolute Maximum Ratings table. Figure 37 shows how a series input resistor can be added to the driven input to limit the input current. The added resistor contributes thermal noise at the amplifier input and the value must be kept to a minimum in noise-sensitive applications.

Figure 37. Input Current Protection

Figure 37. Input Current Protection

7.3.4 Common-Mode Rejection Ratio (CMRR)

CMRR for the OPAx316-Q1 is specified in several ways so the user can select the best match for a given application, as shown in the Electrical Characteristics table. First, the data sheet gives the CMRR of the device in the common-mode range below the transition region [VCM < (V+) – 1.4 V]. This specification is the best indicator of device capability when the application requires use of one of the differential input pairs. Second, the CMRR over the entire common-mode range is specified at VCM = –0.2 V to 5.7 V for VS = 5.5 V. This last value includes the variations shown in Figure 4 through the transition region.

7.3.5 EMI Susceptibility and Input Filtering

Operational amplifiers vary with regard to the susceptibility of the device to electromagnetic interference (EMI). If conducted EMI enters the operational amplifier, the dc offset observed at the amplifier output can shift from the nominal value when EMI is present. This shift is a result of signal rectification associated with the internal semiconductor junctions. Although EMI can affect all operational amplifier pin functions, the signal input pins are likely to be the most susceptible. The OPA316-Q1 operational amplifier family incorporates an internal input low-pass filter that reduces the amplifier response to EMI. This filter provides both common-mode and differential-mode filtering. The filter is designed for a cutoff frequency of approximately 80 MHz (–3 dB), with a roll-off of 20 dB per decade.

TI developed the ability to accurately measure and quantify the immunity of an operational amplifier over a broad frequency spectrum extending from 10 MHz to 6 GHz. The EMI rejection ratio (EMIRR) metric allows operational amplifiers to be directly compared by the EMI immunity. Figure 35 illustrates the testing results on the OPAx316-Q1. For more information, see EMI Rejection Ratio of Operational Amplifiers.

7.3.6 Rail-to-Rail Output

Designed as a low-power, low-noise operational amplifier, the OPAx316-Q1 delivers a robust output drive capability. A class AB output stage with common-source transistors achieves full rail-to-rail output swing capability. For resistive loads of 10-kΩ, the output swings typically to within 30 mV of either supply rail regardless of the power-supply voltage applied. Different load conditions change the ability of the amplifier to swing close to the rails; see Figure 11.

7.3.7 Capacitive Load and Stability

The OPAx316-Q1 is designed for applications where driving a capacitive load is required. As with all operational amplifiers, there may be specific instances where the OPAx316-Q1 can become unstable. The particular operational amplifier circuit configuration, layout, gain, and output loading are some of the factors to consider when establishing whether or not an amplifier is stable in operation. An operational amplifier in the unity-gain

(1 V/V) buffer configuration that drives a capacitive load exhibits a greater tendency to be unstable than an amplifier operated at a higher noise gain. The capacitive load, in conjunction with the operational amplifier output resistance, creates a pole within the feedback loop that degrades the phase margin. The degradation of the phase margin increases as the capacitive loading increases. As a conservative best practice, designing for 25% overshoot (40° phase margin) provides improved stability over process variations. The equivalent series resistance (ESR) of some very-large capacitors (CL with a value greater than 1 μF) is sufficient to alter the phase characteristics in the feedback loop such that the amplifier remains stable. Increasing the amplifier closed-loop gain allows the amplifier to drive increasingly larger capacitance. This increased capability is evident when observing the overshoot response of the amplifier at higher voltage gains. See Figure 24 (G = –1 V/V) and Figure 25 (G = 1 V/V).

Inserting a small resistor (typically 10-Ω to 20-Ω) can increase the capacitive load capability of the amplifier in a unity-gain configuration, as shown in Figure 38. This resistor significantly reduces the overshoot and ringing associated with large capacitive loads. One possible problem with this technique, however, is that a voltage divider is created with the added series resistor and any resistor connected in parallel with the capacitive load. The voltage divider introduces a gain error at the output that reduces the output swing.

Figure 38. Improving Capacitive Load Drive

Figure 38. Improving Capacitive Load Drive

7.3.8 Overload Recovery

Overload recovery is defined as the time required for the operational amplifier output to recover from a saturated state to a linear state. The output devices of the operational amplifier enter a saturation region when the output voltage exceeds the rated operating voltage, either because of the high input voltage or the high gain. After the device enters the saturation region, the charge carriers in the output devices require time to return back to the linear state. After the charge carriers return back to the linear state, the device begins to slew at the specified slew rate. Thus, the propagation delay in case of an overload condition is the sum of the overload recovery time and the slew time. The overload recovery time for the OPAx316-Q1 is approximately 300 ns.

7.4 Device Functional Modes

The OPAx316-Q1 devices are powered on when the supply is connected. The devices can operate as a single-supply operational amplifier or a dual-supply amplifier, depending on the application.

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

8.1.1 General Configurations

When receiving low-level signals, the device often requires limiting the bandwidth of the incoming signals into the system. The simplest way to establish this limited bandwidth is to place an RC filter at the noninverting pin of the amplifier, as Figure 39 shows.

Figure 39. Single-Pole Low-Pass Filter

Figure 39. Single-Pole Low-Pass Filter

If even more attenuation is needed, the device requires a multiple-pole filter. The Sallen-Key filter can be used for this task, as Figure 40 shows. For best results, the amplifier must have a bandwidth that is eight to 10 times the filter frequency bandwidth. Failure to follow this guideline can result in phase shift of the amplifier.

Figure 40. Two-Pole, Low-Pass, Sallen-Key Filter

Figure 40. Two-Pole, Low-Pass, Sallen-Key Filter

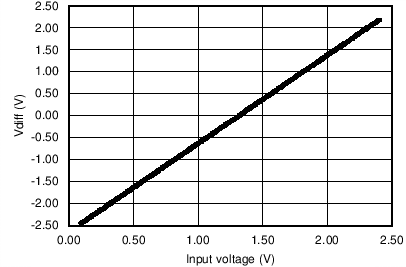

8.2 Typical Application

Some applications require differential signals. Figure 41 shows a simple circuit to convert a single-ended input of 0.1 V to 2.4 V into a differential output of ±2.3 V on a single 2.7-V supply. The output range is intentionally limited to maximize linearity. The circuit is composed of two amplifiers. One amplifier functions as a buffer and creates a voltage (VOUT+). The second amplifier inverts the input and adds a reference voltage to generate VOUT–. VOUT+ and VOUT– range from 0.1 V to 2.4 V. The difference (VDIFF) is the difference between VOUT+ and VOUT– , resulting in a differential output voltage range of 2.3 V.

Figure 41. Schematic for a Single-Ended Input to Differential Output Conversion

Figure 41. Schematic for a Single-Ended Input to Differential Output Conversion

8.2.1 Design Requirements

Table 1 lists the design requirements:

Table 1. Design Parameters

| DESIGN PARAMETER | VALUE |

|---|---|

| Supply voltage | 2.7 V |

| Reference voltage | 2.5 V |

| Input voltage | 0.1 V to 2.4 V |

| Output differential voltage | ±2.3 V |

| Output common-mode voltage | 1.25 V |

| Small-signal bandwidth | 5 MHz |

8.2.2 Detailed Design Procedure

The circuit in Figure 41 takes a single-ended input signal (VIN) and generates two output signals (VOUT+ and VOUT–) using two amplifiers and a reference voltage (VREF). VOUT+ is the output of the first amplifier and is a buffered version of the input signal (VIN) , as shown in Equation 1. VOUT– is the output of the second amplifier that uses VREF to add an offset voltage to VIN and feedback to add inverting gain. The transfer function for VOUT– is given in Equation 2.

The differential output signal (VDIFF) is the difference between the two single-ended output signals (VOUT+ and VOUT–). Equation 3 shows the transfer function for VDIFF. Using conditions in Equation 4 and Equation 5 and applying the conditions that R1 = R2 and R3 = R4, the transfer function is simplified into Equation 6. Using this configuration, the maximum input signal is equal to the reference voltage, and the maximum output of each amplifier is equal to VREF. The differential output range is 2 × VREF. Furthermore, the common-mode voltage is one half of VREF, as shown in Equation 7.

8.2.2.1 Amplifier Selection

Linearity over the input range is key for good dc accuracy. The common-mode input range and output swing limitations determine the linearity. In general, an amplifier with rail-to-rail input and output swing is required. Bandwidth is a key concern for this design, so the OPAx316-Q1 is selected because the bandwidth is greater than the target of 5 MHz. The bandwidth and power ratio makes this device power efficient and the low offset and drift ensure good accuracy for moderate precision applications.

8.2.2.2 Passive Component Selection

Because the transfer function of VOUT– is heavily reliant on resistors (R1, R2, R3, and R4), use resistors with low tolerances to maximize performance and minimize error. This design uses resistors with resistance values of 49.9-kΩ and tolerances of 0.1%. However, if the noise of the system is a key parameter, smaller resistance values (6-kΩ or lower) can be selected to keep the overall system noise low. This ensures that the noise from the resistors is lower than the amplifier noise.

8.2.3 Application Curves

The measured transfer functions in Figure 42, Figure 43, and Figure 44 are generated by sweeping the input voltage from 0.1 V to 2.4 V. The full input range is actually 0 V to 2.5 V, but is restricted to 0.1 V to maintain optimal linearity. For more details on this design and other alternative devices that can be used in place of the OPAx316-Q1, see Single-Ended Input to Differential Output Conversion Circuit Reference Design.

9 Power Supply Recommendations

The OPAx316-Q1 family is specified for operation from 1.8 V to 5.5 V (±0.9 V to ±2.75 V); many specifications apply from –40°C to +125°C. The Typical Characteristics section presents parameters that can exhibit significant variance with regard to operating voltage or temperature.

CAUTION

Supply voltages larger than 7 V can permanently damage the device; see the Absolute Maximum Ratings table.

Place 0.1-μF bypass capacitors close to the power-supply pins to reduce errors coupling in from noisy or high-impedance power supplies. For more information on bypass capacitor placement, see the Layout Guidelines section.

10 Layout

10.1 Layout Guidelines

For best operational performance of the device, use good PCB layout practices, including:

- Noise can propagate into analog circuitry through the power pins of the circuit as a whole and the operational amplifier. Bypass capacitors reduce the coupled noise by providing low-impedance power sources local to the analog circuitry.

- Connect low-ESR, 0.1-µF ceramic bypass capacitors between each supply pin and ground, placed as close to the device as possible. A single bypass capacitor from V+ to ground is applicable for single-supply applications.

- Separate grounding for analog and digital portions of the circuitry is one of the simplest and most effective methods of noise suppression. One or more layers on multilayer PCBs are typically devoted to ground planes. A ground plane helps distribute heat and reduces EMI noise pickup. Take care to physically separate digital and analog grounds, paying attention to the flow of the ground current.

- To reduce parasitic coupling, run the input traces as far away from the supply or output traces as possible. If these traces cannot be kept separate, crossing the sensitive trace perpendicularly is much better than crossing in parallel with the noisy trace.

- Place the external components as close to the device as possible. Keeping RF and RG close to the inverting input minimizes parasitic capacitance, as shown in Figure 45 .

- Keep the length of input traces as short as possible. Remember that the input traces are the most sensitive part of the circuit.

- Consider a driven, low-impedance guard ring around the critical traces. A guard ring can significantly reduce leakage currents from nearby traces that are at different potentials.

10.2 Layout Example

Figure 45. Operational Amplifier Board Layout for Noninverting Configuration

Figure 45. Operational Amplifier Board Layout for Noninverting Configuration

11 デバイスおよびドキュメントのサポート

11.1 ドキュメントのサポート

11.2 関連リンク

Table 2 に、クイック・アクセス・リンクの一覧を示します。カテゴリには、技術資料、サポートおよびコミュニティ・リソース、ツールとソフトウェア、およびサンプル注文またはご購入へのクイック・アクセスが含まれます。

11.3 ドキュメントの更新通知を受け取る方法

ドキュメントの更新についての通知を受け取るには、ti.comのデバイス製品フォルダを開いてください。右上の隅にある「通知を受け取る」をクリックして登録すると、変更されたすべての製品情報に関するダイジェストを毎週受け取れます。変更の詳細については、修正されたドキュメントに含まれている改訂履歴をご覧ください。

11.4 コミュニティ・リソース

The following links connect to TI community resources. Linked contents are provided "AS IS" by the respective contributors. They do not constitute TI specifications and do not necessarily reflect TI's views; see TI's Terms of Use.

-

TI E2E™オンライン・コミュニティ TIのE2E(Engineer-to-Engineer)コミュニティ。エンジニア間の共同作業を促進するために開設されたものです。e2e.ti.comでは、他のエンジニアに質問し、知識を共有し、アイディアを検討して、問題解決に役立てることができます。

-

設計サポート TIの設計サポート 役に立つE2Eフォーラムや、設計サポート・ツールをすばやく見つけることができます。技術サポート用の連絡先情報も参照できます。

11.5 商標

E2E is a trademark of Texas Instruments.

11.6 静電気放電に関する注意事項

これらのデバイスは、限定的なESD(静電破壊)保護機能を内 蔵しています。保存時または取り扱い時は、MOSゲートに対す る静電破壊を防止するために、リード線同士をショートさせて おくか、デバイスを導電フォームに入れる必要があります。

11.7 Glossary

SLYZ022 — TI Glossary.

This glossary lists and explains terms, acronyms, and definitions.

12 メカニカル、パッケージ、および注文情報

以降のページには、メカニカル、パッケージ、および注文に関する情報が記載されています。この情報は、そのデバイスについて利用可能な最新のデータです。このデータは予告なく変更されることがあり、ドキュメントが改訂される場合もあります。本データシートのブラウザ版を使用されている場合は、画面左側の説明をご覧ください。

IMPORTANT NOTICE

Texas Instruments Incorporated (TI) reserves the right to make corrections, enhancements, improvements and other changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and complete.

TI’s published terms of sale for semiconductor products (http://www.ti.com/sc/docs/stdterms.htm) apply to the sale of packaged integrated circuit products that TI has qualified and released to market. Additional terms may apply to the use or sale of other types of TI products and services.

Reproduction of significant portions of TI information in TI data sheets is permissible only if reproduction is without alteration and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such reproduced documentation. Information of third parties may be subject to additional restrictions. Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Buyers and others who are developing systems that incorporate TI products (collectively, “Designers”) understand and agrees that Designers remain responsible for using their independent analysis, evaluation and judgment in designing their systems and products, and have full and exclusive responsibility to assure the safety of their products and compliance of their products (and of all TI products used in or for such Designers’ products) with all applicable regulations, laws and other applicable requirements. Designers represent that, with respect to their applications, they have all the necessary expertise to create and implement safeguards that (1) anticipate dangerous consequences of failures, (2) monitor failures and their consequences, and (3) lessen the likelihood of failures that might cause harm and take appropriate actions. Designers agree that prior to using or distributing any systems that include TI products, they will thoroughly test such systems and the functionality of such TI products as used in such systems.

TI’s provision of reference designs and any other technical, applications or design advice, quality characterization, reliability data or other information or services does not expand or otherwise alter TI’s applicable published warranties or warranty disclaimers for TI products, and no additional obligations or liabilities arise from TI providing such reference designs or other items.

Designers are authorized to use, copy and modify any individual TI reference design only in connection with the development of end products that include the TI product(s) identified in that reference design. HOWEVER, NO OTHER LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE TO ANY OTHER TI INTELLECTUAL PROPERTY RIGHT, AND NO LICENSE TO ANY TECHNOLOGY OR INTELLECTUAL PROPERTY RIGHT OF TI OR ANY THIRD PARTY IS GRANTED HEREIN, including but not limited to any patent right, copyright, mask work right, or other intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information published by TI regarding third-party products or services does not constitute a license to use such products or services, or a warranty or endorsement thereof. Use of the reference design or other items described above may require a license from a third party under the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI.

TI REFERENCE DESIGNS AND OTHER ITEMS DESCRIBED ABOVE ARE PROVIDED “AS IS” AND WITH ALL FAULTS. TI DISCLAIMS ALL OTHER WARRANTIES OR REPRESENTATIONS, EXPRESS OR IMPLIED, REGARDING THE REFERENCE DESIGNS OR USE OF THE REFERENCE DESIGNS, INCLUDING BUT NOT LIMITED TO ACCURACY OR COMPLETENESS, TITLE, ANY EPIDEMIC FAILURE WARRANTY AND ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF ANY THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

TI SHALL NOT BE LIABLE FOR AND SHALL NOT DEFEND OR INDEMNIFY DESIGNERS AGAINST ANY CLAIM, INCLUDING BUT NOT LIMITED TO ANY INFRINGEMENT CLAIM THAT RELATES TO OR IS BASED ON ANY COMBINATION OF PRODUCTS AS DESCRIBED IN A TI REFERENCE DESIGN OR OTHERWISE. IN NO EVENT SHALL TI BE LIABLE FOR ANY ACTUAL, DIRECT, SPECIAL, COLLATERAL, INDIRECT, PUNITIVE, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY DAMAGES IN CONNECTION WITH OR ARISING OUT OF THE REFERENCE DESIGNS OR USE OF THE REFERENCE DESIGNS, AND REGARDLESS OF WHETHER TI HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Unless TI has explicitly designated an individual product as meeting the requirements of a particular industry standard (e.g., ISO/TS 16949 and ISO 26262), TI is not responsible for any failure to meet such industry standard requirements.

Where TI specifically promotes products as facilitating functional safety or as compliant with industry functional safety standards, such products are intended to help enable customers to design and create their own applications that meet applicable functional safety standards and requirements. Using products in an application does not by itself establish any safety features in the application. Designers must ensure compliance with safety-related requirements and standards applicable to their applications. Designer may not use any TI products in life-critical medical equipment unless authorized officers of the parties have executed a special contract specifically governing such use. Life-critical medical equipment is medical equipment where failure of such equipment would cause serious bodily injury or death (e.g., life support, pacemakers, defibrillators, heart pumps, neurostimulators, and implantables). Such equipment includes, without limitation, all medical devices identified by the U.S. Food and Drug Administration as Class III devices and equivalent classifications outside the U.S.

TI may expressly designate certain products as completing a particular qualification (e.g., Q100, Military Grade, or Enhanced Product). Designers agree that it has the necessary expertise to select the product with the appropriate qualification designation for their applications and that proper product selection is at Designers’ own risk. Designers are solely responsible for compliance with all legal and regulatory requirements in connection with such selection.

Designer will fully indemnify TI and its representatives against any damages, costs, losses, and/or liabilities arising out of Designer’s non-compliance with the terms and provisions of this Notice.

IMPORTANT NOTICE

| Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265 Copyright © 2017, Texas Instruments Incorporated |