JAJSNM7C December 2021 – September 2024 REF35

PRODUCTION DATA

- 1

- 1 特長

- 2 アプリケーション

- 3 概要

- 4 Device Comparison

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Parameter Measurement Information

- 8 Detailed Description

- 9 Application and Implementation

- 10Device and Documentation Support

- 11Revision History

- 12Mechanical, Packaging, and Orderable Information

パッケージ・オプション

デバイスごとのパッケージ図は、PDF版データシートをご参照ください。

メカニカル・データ(パッケージ|ピン)

- DBV|6

- YBH|4

サーマルパッド・メカニカル・データ

発注情報

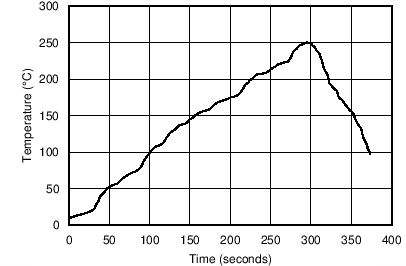

7.1 Solder Heat Shift

The materials used in the manufacture of the REF35 have differing coefficients of thermal expansion, resulting in stress on the device die when the part is heated. Mechanical and thermal stress on the device die can cause the output voltages to shift, degrading the initial accuracy specifications of the product. Reflow soldering is a common cause of this error.

To illustrate this effect, a total of 32 devices

were soldered on one printed circuit board using lead-free solder paste and the paste

manufacturer suggested reflow profile. Figure 7-1 shows the reflow profile. The printed circuit board is comprised of FR4 material. The

board thickness is 1.66mm and the area is

174mm × 135mm.

Figure 7-1 Reflow

Profile

Figure 7-1 Reflow

ProfileThe reference output voltage is measured before and after the reflow process; Figure 7-2 shows the typical shift. Although all tested units exhibit very low shifts (< 0.03%), higher shifts are also possible depending on the size, thickness, and material of the printed circuit board (PCB). An important note is that the histograms display the typical shift for exposure to a single reflow profile. Exposure to multiple reflows, as is common on PCBs with surface-mount components on both sides, causes additional shifts in the output bias voltage. If the PCB is exposed to multiple reflows, the device must be soldered in the last pass to minimize its exposure to thermal stress.

Figure 7-2 Solder Heat Shift

Distribution, VREF (%)

Figure 7-2 Solder Heat Shift

Distribution, VREF (%)