SLLS814A July 2007 – June 2015 TRS3221

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

-

6 Specifications

- 6.1 Absolute Maximum Ratings

- 6.2 ESD Ratings

- 6.3 Recommended Operating Conditions

- 6.4 Thermal Information

- 6.5 Electrical Characteristics—Power

- 6.6 Electrical Characteristics—Driver

- 6.7 Electrical Characteristics—Receiver

- 6.8 Electrical Characteristics—Status

- 6.9 Switching Characteristics—Driver

- 6.10 Switching Characteristics—Receiver

- 6.11 Switching Characteristics—Status

- 6.12 Typical Characteristics

- 7 Parameter Measurement Information

- 8 Detailed Description

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

パッケージ・オプション

メカニカル・データ(パッケージ|ピン)

サーマルパッド・メカニカル・データ

発注情報

9 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

9.1 Application Information

The TRS3232 device is designed to convert single-ended signals into RS232-compatible signals, and vice-versa.

This device can be used in any application where an RS232 line driver or receiver is required. One benefit of this device is its ESD protection, which helps protect other components on the board when the RS232 lines are tied to a physical connector.

9.2 Typical Application

9.2.1 Design Requirements

- Recommended VCC is 3.3 V or 5 V

- 3 V to 5.5 V is also possible

- Maximum recommended bit rate is 250 kbps

- Use capacitors as shown in Figure 9 and Table 4

Table 4. VCC versus Capacitor Values

| VCC | C1 | C2, C3, and C4 |

|---|---|---|

| 3.3 V ± 0.3 V | 0.1 µF | 0.1 µF |

| 5 V ± 0.5 V | 0.047 µF | 0.33 µF |

| 3 V to 5.5 V | 0.1 µF | 0.47 µF |

9.2.2 Detailed Design Procedure

For proper operation, add capacitors as shown in Figure 9 and Table 4.

- DIN, FORCEOFF and FORCEON inputs must be connected to valid low or high logic levels

- Select capacitor values based on VCC level for best performance

ROUT and DIN connect to UART or general purpose logic lines. FORCEON and FORCEOFF may be connected general purpose logic lines or tied to ground or VCC. INVALID may be connected to a general purpose logic line or left unconnected. RIN and DOUT lines connect to a RS232 connector or cable. DIN, FORCEON, and FORCEOFF inputs must not be left unconnected.

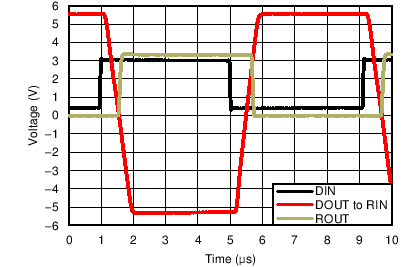

9.2.3 Application Curve

VCC of 3.3 V and 250 kbps alternative bit data stream

Figure 10. 250 kbps Driver to Receiver Loopback Timing Waveform,

Figure 10. 250 kbps Driver to Receiver Loopback Timing Waveform,VCC= 3.3 V