SLAAE71 December 2022 MSPM0G1105 , MSPM0G1106 , MSPM0G1107 , MSPM0G1505 , MSPM0G1506 , MSPM0G1507 , MSPM0G3105 , MSPM0G3106 , MSPM0G3107 , MSPM0G3505 , MSPM0G3506 , MSPM0G3507

- Abstract

- Trademarks

- 1Overview

- 2Low-Power Features in PMCU

- 3Low-Power Optimization

- 4Power Consumption Measurement and Evaluation

4.2.1 Current Measurement

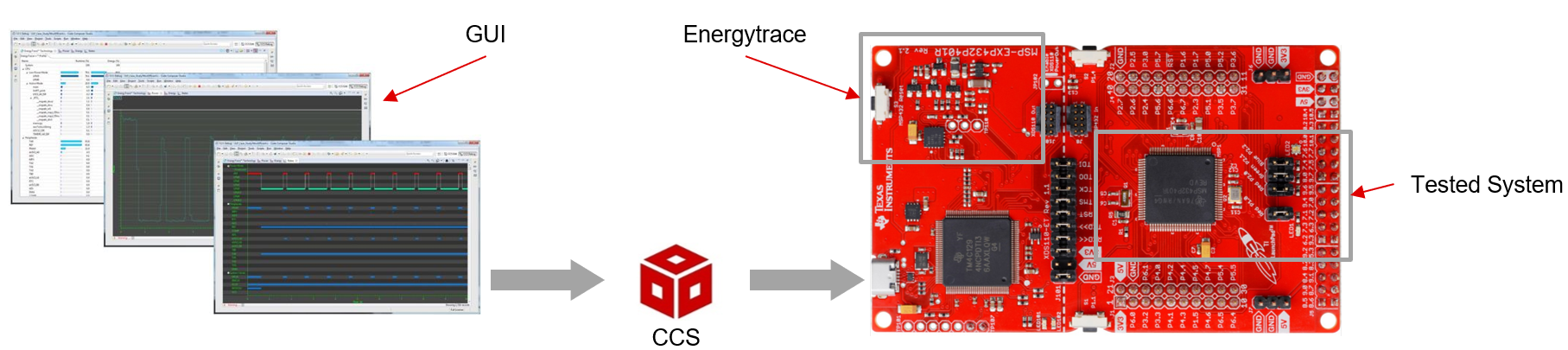

EnergyTrace™ technology is a power analyzer hardware tool to detect average power consumption pared with Code Composer Studio IDE (CCS). It is exported through a USB bulk endpoint in the XDS110 Debug Probe on every MSPM0 LaunchPad™ development kit. The work system is shown as Figure 4-1.

Figure 4-1 EnergyTrace Technology Work Flow

Figure 4-1 EnergyTrace Technology Work FlowEnergyTrace implements a new method for measuring current consumption for ultra-low power currents. A software-controlled DC-DC converter generates the target power supply and keeps it regulated via a train of pulses. The density of the DC/DC converter charge pulses is proportional to the energy consumption of the target microcontroller. Because the width of each charge pulse remains constant, the Debug Probe simply counts each charge pulse and then sums them over time to calculate the average current. The accuracy of measurements is controlled by a built-in calibration circuit in the debug probe, which quantifies the energy equivalent of a single charge pulse. Using this approach, even the shortest device activity that consumes energy contributes to the overall recorded energy. The XDS110 user's guide and EnergyTrace technology website contain additional details.

Table 4-1 lists the basic electrical specifications.

| Range | Accuracy | Observations |

|---|---|---|

| I < 25 mA | ±2% ±500 nA | VBUS = 5 V constant during and after calibration |

| I > 25 mA and I < 75 mA | ±5% ±500 nA | VBUS = 5 V constant during and after calibration |