SLUUCH4A October 2021 – October 2023 BQ27Z746

- 1

- Abstract

- Trademarks

- 1 Software Setup

- 2 Troubleshooting Unexpected Dialog Boxes

- 3 Hardware Setup

- 4 Using bqStudio

- 5 Calibrating Gauge Measurements

- 6 Protections

- 7 Chemical ID

- 8 Learning Cycle and Golden Image

- 9 Gauge Communication

- 10BQ27Z746-Based Circuit Module

- 11Circuit Module Physical Layout, Bill of Materials, and Schematic

- Revision History

7.1 Chemical ID Selection Process Description

The test consists of the following steps:

- Test is performed at room temperature. If the cell was at a different temperature, let the cell relax for two hours at room temperature prior to the test.

- Charge using CC or CV charging to full using taper current (for example, C/100). Use nominal CC charge rate and CV voltage. If another charging method is specified by the cell maker, use that method.

- Let the battery relax for two hours to reach full equilibrium open circuit voltage (OCV).

- Discharge the battery at C/10 rate until the minimal voltage (as specified by the cell manufacturer) is reached.

- Let the battery relax for five hours to reach full equilibrium OCV.

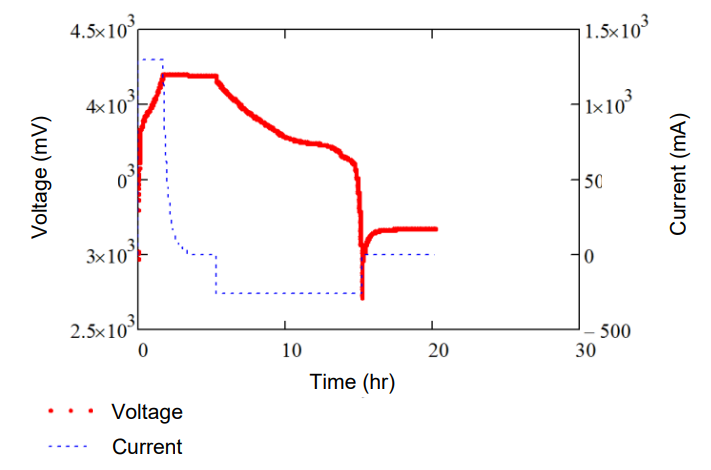

Figure 8-1 shows an example of what this process looks like graphically.

Figure 7-1 Graph of IV Data in

Charge-Relax-Discharge-Relax

Figure 7-1 Graph of IV Data in

Charge-Relax-Discharge-Relax