SLVSAB3I May 2010 – January 2016

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

The DRV8832 is used in brushed DC applications to provide a constant motor speed over varying voltages. The following design procedure can be used to configure the DRV8832 for a system with a VCC variance of 4 V to

6 V.

8.2 Typical Application

Figure 9 shows a common application of the DRV8832.

Figure 9. Typical Application Schematic

Figure 9. Typical Application Schematic

8.2.1 Design Requirements

Table 4 lists the design parameters for this application.

Table 4. Design Parameters

| DESIGN PARAMETER | REFERENCE | EXAMPLE VALUE |

|---|---|---|

| Motor voltage | VCC | 4 V |

| Motor RMS current | IRMS | 0.3 A |

| Motor start-up current | ISTART | 0.6 A |

| Motor current trip point | ILIMIT | 0.5 A |

8.2.2 Detailed Design Procedure

8.2.2.1 Motor Voltage

The motor voltage to use will depend on the ratings of the motor selected and the desired RPM. A higher voltage spins a brushed DC motor faster with the same PWM duty cycle applied to the power FETs. A higher voltage also increases the rate of current change through the inductive motor windings.

For the DRV8832, TI recommends setting a motor voltage at the lowest system VCC. This will maintain a constant RPM across varying VCC conditions.

For example if the VCC voltage can vary from 4.5 V to 5.5 V, setting the VSET voltage to 1.125 V will compensate for power supply variation. The DRV8832 will set the motor voltage at 4.5 V, even if VCC is 5.5 V.

8.2.2.2 Motor Current Trip Point

When the voltage on pin ISENSE exceeds VILIM (0.2 V), overcurrent is detected. The RSENSE resistor should be sized to set the desired ILIMIT level.

To set ILIMIT to 5 A, RISENSE = 0.2 V / 0.5 A = 0.4 Ω.

To prevent false trips, ILIMIT must be higher than regular operating current. Motor current during start-up is typically much higher than steady-state spinning, because the initial load torque is higher, and the absence of back-EMF causes a higher voltage and extra current across the motor windings.

It can be beneficial to limit start-up current by using series inductors on the DRV8832 output, as that allows ILIMIT to be lower, and it may decrease the system’s required bulk capacitance. Start-up current can also be limited by ramping the forward drive duty cycle.

8.2.2.3 Sense Resistor

For optimal performance, it is important for the sense resistor to be:

- Surface-mount

- Low inductance

- Rated for high enough power

- Placed closely to the motor driver

The power dissipated by the sense resistor equals IRMS2 × R. For example, if peak motor current is 1 A, RMS motor current is 0.7 A, and a 0.4-Ω sense resistor is used, the resistor will dissipate 0.7 A2× 0.4 Ω = 0.2 W. The power quickly increases with higher current levels.

Resistors typically have a rated power within some ambient temperature range, along with a derated power curve for high ambient temperatures. When a PCB is shared with other components generating heat, margin should be added. It is always best to measure the actual sense resistor temperature in a final system, along with the power MOSFETs, as those are often the hottest components.

Because power resistors are larger and more expensive than standard resistors, it is common practice to use multiple standard resistors in parallel, between the sense node and ground. This distributes the current and heat dissipation.

8.2.2.4 Low Power Operation

Under normal operation, using sleep mode to minimize supply current should be sufficient.

If desired, power can be removed to the DRV8832 to further decrease supply current. TI recommends removing power to the FAULTn pullup resistor when removing power to the DRV8832. Removing power from the FAULTn pullup resistor will eliminate a current path from the FAULTn pin through an ESD protection diode to VCC. TI also recommends setting both IN1 and IN2 as a logic low when power is removed.

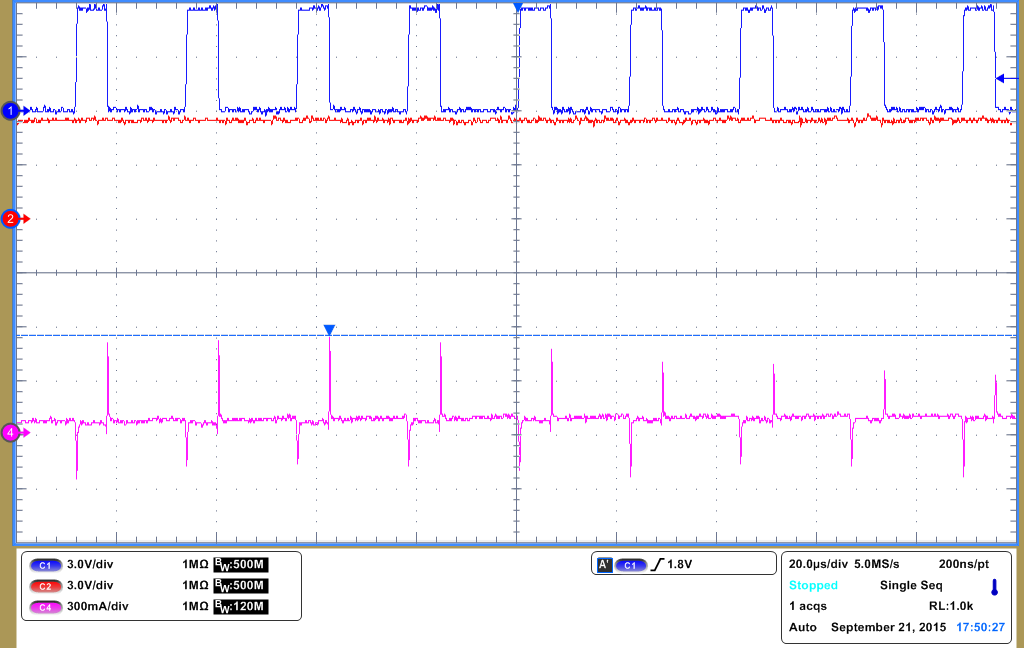

8.2.3 Application Curves

The following scope captures show how the output duty cycle changes to as VCC increases. This allows the motor to spin at a constant speed as VCC changes. At VCC=3.9V, the output duty cycle is 100% on. As the VCC voltage increases to greater than 4 V, the output duty cycle begins to decrease. The output duty cycle is shown at VCC=4.5 V, VCC=5 V and VCC=5.5 V.

- Channel 1 – OUT1: IN1 – Logic Low

- Channel 2 – OUT2: IN2 – Logic High

- Channel 4 – Motor current: VSET – 1 V

- Motor used: NMB Technologies Corporation, PPN7PA12C1

Figure 10. Output Pulse Width Modulating at VCC = 3.9 V

Figure 10. Output Pulse Width Modulating at VCC = 3.9 V

Figure 12. Output Pulse Width Modulating at VCC = 4.5 V

Figure 12. Output Pulse Width Modulating at VCC = 4.5 V

Figure 14. Output Pulse Width Modulating at VCC = 5.5 V

Figure 14. Output Pulse Width Modulating at VCC = 5.5 V

Figure 11. Output Pulse Width Modulating at VCC = 4 V

Figure 11. Output Pulse Width Modulating at VCC = 4 V

Figure 13. Output Pulse Width Modulating at VCC = 5 V

Figure 13. Output Pulse Width Modulating at VCC = 5 V