SLVUCX2A June 2024 – January 2025

2.3 EVM Hardware Quick-Start

This section describes the steps to prepare the DRV8351EVM for first motor spin-up. This section assumes the default jumper positions mentioned above are used.

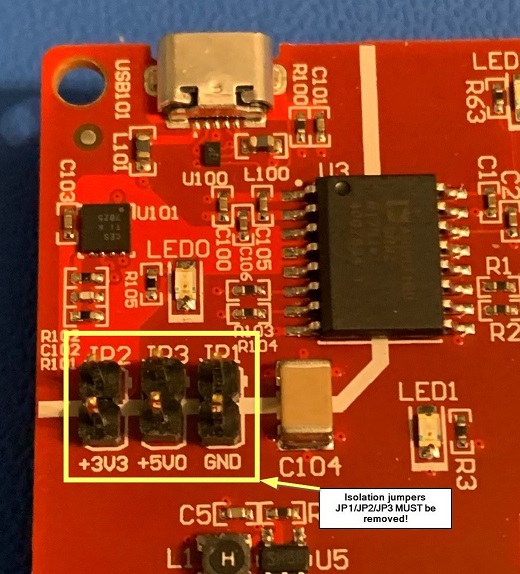

Figure 2-7 JP1/JP2/JP3 Removed

Figure 2-7 JP1/JP2/JP3 Removed- Make sure that the isolation jumpers JP1/JP2/JP3 on the LAUNCHXL-F280049C have been removed.

- Plug the DRV8351EVM onto the lower position of the LAUNCHXL-F280049C board.

- Connect motor phase connections to the respective MOTA/MOTB/MOTC inputs on J5, making sure to match A, B, and C.

- Connect the hall sensor connections, hall power, and ground to J7. Make sure that Hall A, B, and C are in the correct order.

- Connect the provided micro-USB cable to the LAUNCHXL-F280049C.

- Connect PVDD and GND to connector J4. A low current limit of 300mA on the PVDD supply is recommended for first power-up to make sure the EVM is connected correctly. If there is no issue upon power-up, then the current limit can be raised to allow for current based on your motor specifications.

- Start the GUI per the instructions below in the software section.