SPRADB7 September 2023 AM2431 , AM2432 , AM2434 , AM2631 , AM2631-Q1 , AM2632 , AM2632-Q1 , AM2634 , AM2634-Q1 , AM263P4 , AM263P4-Q1 , AM2732 , AM2732-Q1

- 1

- Abstract

- Trademarks

- 1Introduction

- 2Thermal Resistance Overview

- 3Board Design Choices that Affect Thermal Performance

- 4Thermal Design Best Practices Review

- 5AM263x EVM Thermal Comparison with Data

- 6Using the Thermal Model

- 7References

6 Using the Thermal Model

Thermal modeling software such as MentorGraphics Flotherm or ANSYS ICEPAK is used to open the model and build the thermal environment for simulation. The software allows you to build out entire situations and edge cases to estimate thermal performance. The simulation can also be as simple or as detailed as the user requires. For example, an SoC's thermal performance could be simulated using a simple JEDEC-defined 2S2P (two metal planes and two signal layers) test board. The Package thermal characteristics section of a Sitara microcontroller device data sheet has values that are based on a 2S2P system.

To import a device's characteristics into simulation, a thermal model is required. The SoC thermal model is available for all Sitara microcontrollers in the form of an Electronics Cooling XML (ECXML) file. This file type is established by JEDEC as the standard for exchanging electronic thermal system level simulation models to end users. The thermal model provides an accurate representation of the entire SoC design and, therefore, an accurate representation of junction and lid temperature. The thermal model still requires additional configuration and setup in the simulation software to provide the best approximation of a system's thermal profile.

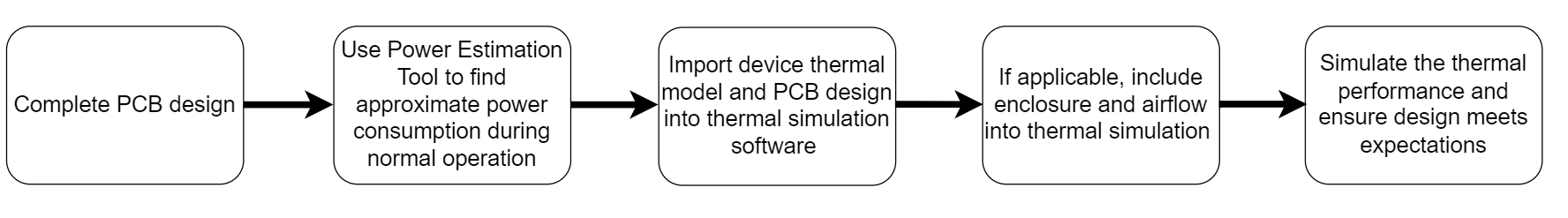

For the best thermal simulation results, the PCB design should be imported into the simulation software as well as the enclosure and airflow properties. Additionally, the device-specific Power Estimation Tool should be used to estimate the operating power of the SoC during operation. The estimated operating power can then be used with the thermal model for an even more accurate representation of the thermal profile.

Figure 6-1 shows the flow for building an accurate system for thermal modeling.

Figure 6-1 Thermal Simulation Flow

Figure 6-1 Thermal Simulation Flow