SPRUJF4A October 2024 – December 2024

- 1

- Description

- Features

- Applications

- 5

- 1Evaluation Module Overview

- 2Hardware

- 3Motor Control Software

-

4Test Procedure and Results

- 4.1 Build Level 1: CPU and Board Setup

- 4.2 Build Level 2: Open-Loop Check With ADC Feedback

- 4.3 Build Level 3: Closed Current Loop Check

- 4.4 Build Level 4: Full Motor Drive Control

- 4.5 Test Procedure

- 4.6 Performance Data and Results

- 5Hardware Design Files

- 6Additional Information

- 7References

- 8Revision History

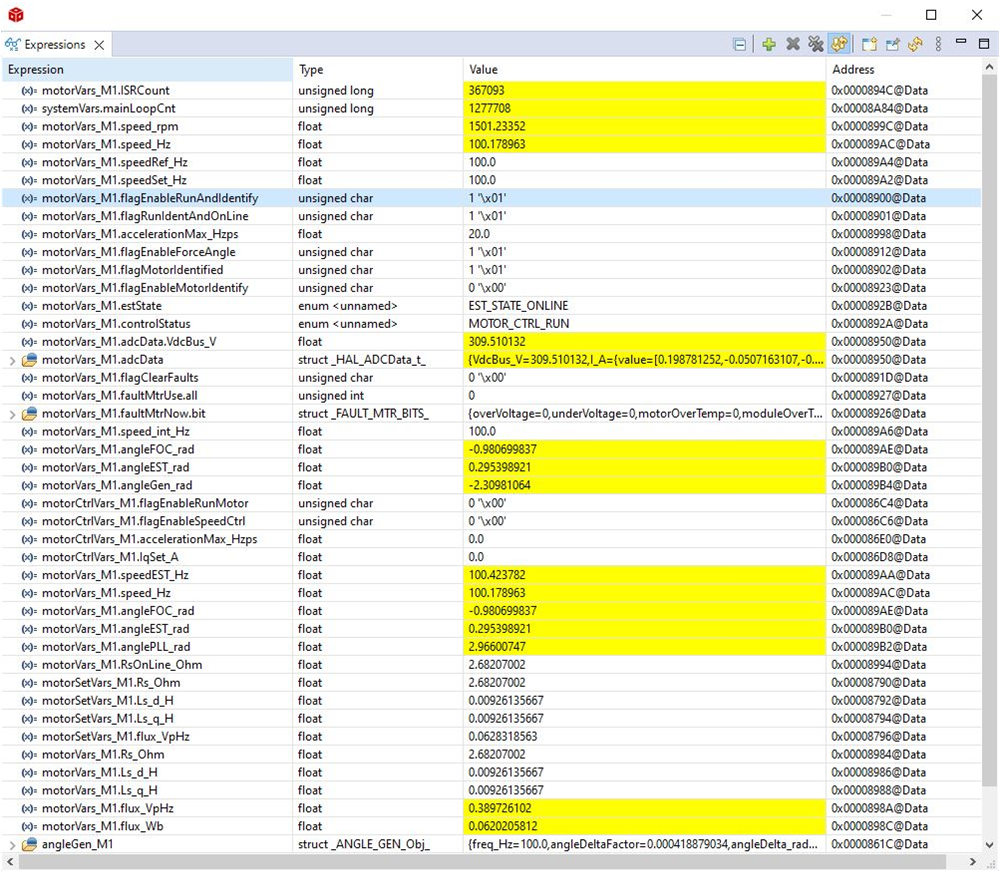

4.5.4.4 Build Level 4 Test Procedure

- Ensure initial steps listed in Section 4.5.4 have been completed.

- If the motor identification

routine is being utilized, as described in Section 4.5.2, the

motor identification routine begins execution immediately upon setting

motorVars_M1.flagEnableRunAndIdentify to "1" in the

Expressions window. This process takes about 150 seconds.

- Once

motorVars_M1.flagEnableRunAndIdentify is equal to "0",

the motor parameters have been identified. Record the watch window

values with the newly-defined motor parameters in user_mtr1.h as

follows:

- USER_MOTOR1_Rs = motorVars_M1.Rs_Ohm’s value

- USER_MOTOR1_Ls_d = motorVars_M1.Ls_d_H’s value

- USER_MOTOR1_Ls_q = motorVars_M1.Ls_q_H’s value

- USER_MOTOR_RATED_FLUX = motorVars_M1.flux_VpHz’s value

- Set userParams_M1.flag_bypassMotorId to "true" after successfully identify the motors parameters, rebuild the project and load the code into the controller.

- Once

motorVars_M1.flagEnableRunAndIdentify is equal to "0",

the motor parameters have been identified. Record the watch window

values with the newly-defined motor parameters in user_mtr1.h as

follows:

- Set the variables motorVars_M1.speedRef_Hz to a different value and watch how the motor shaft speed follows.

- To change the acceleration, enter a different acceleration value for the variables motorVars_M1.accelerationMax_Hzps and motorVars_M1.accelerationMax_Hzps.

Figure 4-14 Build Level 4: Expressions

Window at Run Time

Figure 4-14 Build Level 4: Expressions

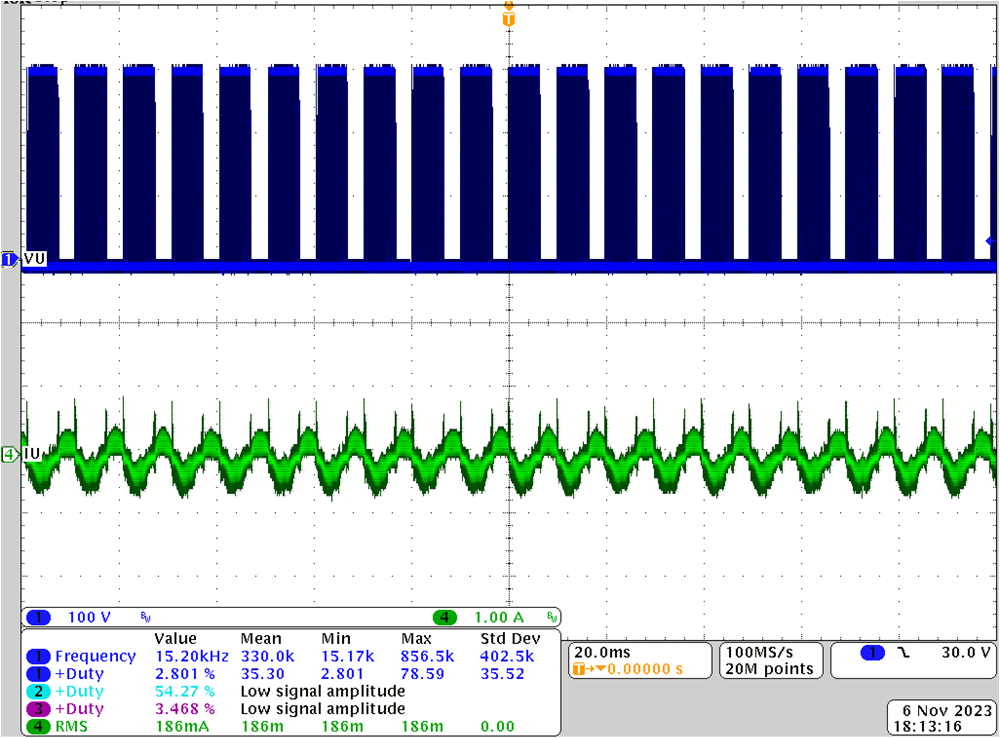

Window at Run Time Figure 4-15 Build Level 4: Rotor Angle,

Phase Current of Motor

Figure 4-15 Build Level 4: Rotor Angle,

Phase Current of MotorAfter these initial tests, Build Level 4 is also where any other test conditions and tuning are optionally performed.