-

Using Dynamic Headroom Control for Industrial Lighting Applications

Using Dynamic Headroom Control for Industrial Lighting Applications

LED signage and lighting applications such as industrial stack lights you might know from industrial machinery or big LED displays that are used in stadiums have a common problem of limited possibilities for power dissipation. It’s important in industrial environments that these lights and signage are able to dissipate the heat that is generated, to maximize the lifetime of the LEDs. When applications are using linear LED drivers it is required that you minimize the voltage drop in the linear LED driver, which in turn requires regulation of the voltage of the supplying regulator based on the LED forward voltage. This technique is called dynamic headroom control.

As long as you always have the same current, the voltage drop of the LEDs will remain constant over temperature and process variations. For example, you could calculate the feedback network of an adjustable regulator to have a residue voltage of 0.5V, which is just a bit above the minimal value. It is necessary to have enough of a voltage drop so the linear regulator can work, even over temperature variation and component tolerances, but it also has to be low voltage to minimize the power dissipation.

In all cases, you should consider the variation of the forward voltage mentioned in the data sheet. For a green LED, this could be between 2.7V and 3.4V at 10mA, so you should set your voltage regulator to at least 3.4V + 0.5V = 3.9V. It is better not to go too close to the minimum value, as you always have tolerances in the reference of the voltage regulator and the resistors.

For one LED the power dissipation will be about 12mW, which is in most cases nothing to worry about. But many applications don’t have just one LED, and you might want to increase the current.

Let’s look at the TLC5971 red-green-blue (RGB) LED driver with one voltage regulator. The blue LED has the highest forward voltage: 3.8V. Thus, you have to design the voltage regulator for 4.3V, maybe with some more headroom for higher current. The device has four RGB channels, so the power dissipation will be up to 4 × ((4.2 – 3) + (4.2 – 2.7) + (4.2 – 2.1)) × 0.01 = 192mW. If you go as high as 20mA and use only one regulator for all colors of 5V (which is available as fixed output voltage) the power dissipation is even higher.

How Can the Power Dissipation Be Reduced?

One way to reduce power dissipation is to use one regulator for each color, or at least one voltage for the red string and another voltage the green and blue strings. The voltage of green and blue is close to another, but the voltage of the red LED string is lower than green and blue.

Figure 1 LED forward voltage of

different colored LEDs

Figure 1 LED forward voltage of

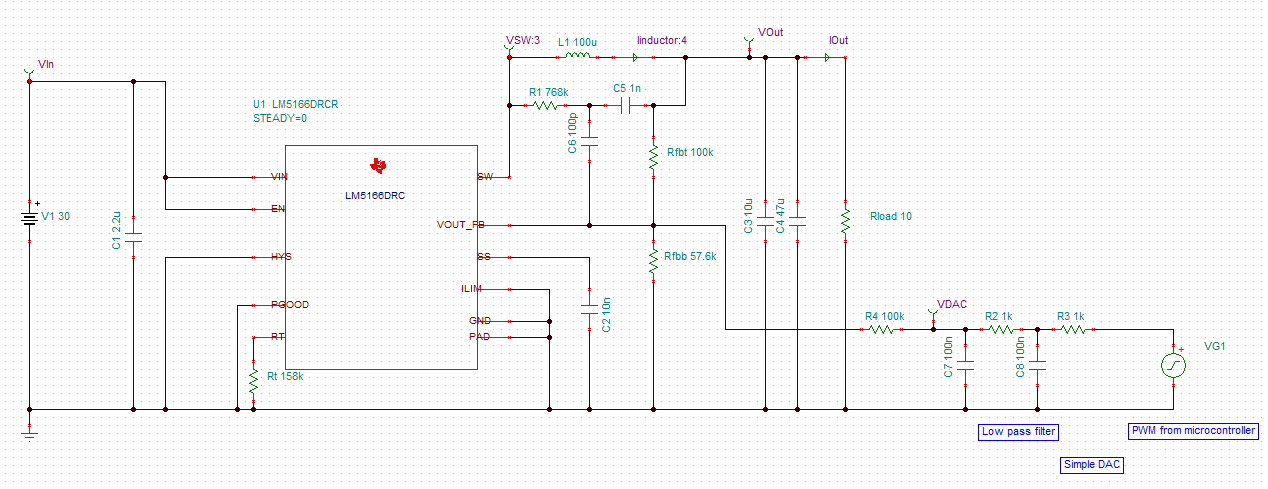

different colored LEDsIt's also possible to achieve a further reduction by adjusting the voltage of each regulator; one easy way is to inject a voltage in the feedback network of a regulator. You could use a digital-to-analog converter (DAC) or build your own DAC by using a pulse-width modulation (PWM) and a low-pass filter. Figure 1 shows a simulation for a controlled voltage regulator. On the right is a PWM signal coming from a microcontroller (MCU), low pass-filtered and injected into the feedback network.

Figure 2 Simulation of a PWM for

controlling a voltage regulator

Figure 2 Simulation of a PWM for

controlling a voltage regulatorAs in most systems where a MCU is present, the MCU can measure the voltage drop of the LED driver and set the PWM for voltage regulator control. This control loop does not have to be fast or very precise, since it does not have a visible effect other than higher power dissipation. You can simulate the whole power supply, including the PWM from the MCU. In the simulation shown in Figure 1, the PWM is generated by a voltage generator configured to generate a 20kHz PWM, with an increasing duty cycle from 0 to 100% within 1s.

The simulation does takes a long time, so you might want to simulate the DAC after changing parameters to verify that it is working. By simulating the two main parts separately, it will speed up the entire simulation. A PWM duty cycle sweep should look like Figure 2.

Figure 3 Resulting DAC voltage on

varying PWM duty cycle

Figure 3 Resulting DAC voltage on

varying PWM duty cycleInjecting a positive voltage into the feedback network will reduce the output voltage depending on the voltage and the resistors. When injecting 0V, the output voltage is at its maximum. Figure 3 shows the effect of the injection on the output voltage.

Figure 4 Simulation results

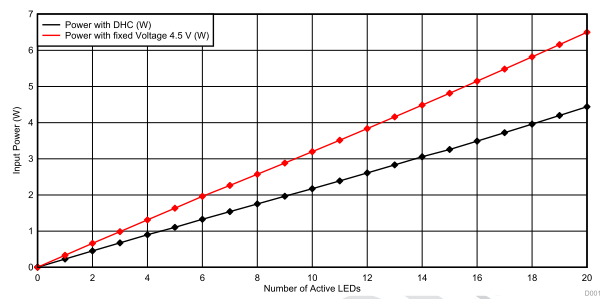

Figure 4 Simulation resultsEffect of DHC on Total Power Consumption

TI implemented dynamic headroom control by injecting voltage in the feedback network in the RGB Signal Light with IO-Link Interface Reference Design for a stack light with 20 RGB LEDs and five TLC5971 LED drivers. As shown in Figure 4, you end up at 6.5W of total system power consumption, with a fixed 4.5V for the LED driver and 20mA current per LED. Enabling the regulation of the voltage to a voltage drop of 0.5V at the LED driver decreases the total power dissipation to 4.5W.

Figure 5 Power dissipation comparison

with and without dynamic headroom control

Figure 5 Power dissipation comparison

with and without dynamic headroom controlThe dynamic headroom control technique can help reduce the high power dissipation of LED signage and lighting applications using LED drivers. The technique enables significant power reductions by giving you the ability to regulate your voltage regulator.

Additional Resources:

- Learn how to light up your design with TI’s LED driver integrated circuits.

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated