SSZTAP8 october 2016

Today’s 3D printing industry is more robust than ever -- and continues to expand. By some estimates, the global 3D printing market will grow from $6 billion in 2015 to an estimated $20 billion by 2020.

There are many reasons fueling this growth. While many developers continue to use 3D printing for rapid prototyping, it is also helping to create final products that cannot be produced with traditional manufacturing techniques such as injection molding.

Getting started with 3D printing can seem like a daunting task but it doesn’t have to be difficult. Once you understand a few basics about the technology, many 3D printers are available at various price points to help reshape your manufacturing capabilities.

One of the biggest considerations with 3D printing is choosing the type of printer technology. The industry is dominated by two types: Fused Deposition Modeling (FDM) and Stereolithography (SLA). SLA requires the ability to precisely control light over a wide variety of wavelengths at high resolution.

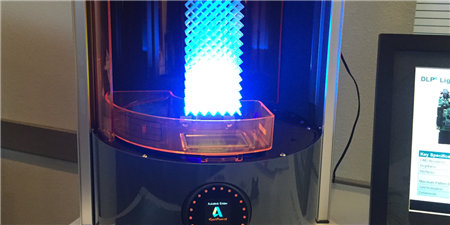

In general, SLA printing uses one light source, typically an ultraviolet (UV) LED or a high power laser, to create a print one layer at a time by curing a liquid resin, thereby creating a solid object. The object being printed starts as a computer-aided design (CAD) model which is converted into a series of cross-sectional slices, representing individual print layers. 3D printers using DLP® technology for SLA allow an entire cross-sectional slice to be exposed in a single shot by projecting a high resolution 2D light pattern. This technique allows the system to be independent of layer complexity, which enables faster build times compared to laser based point-to-point exposure systems.

The reliable digital micromirror device (DMD) at the heart of all DLP Products offers printing precision down to sub-50 micron resolution. It’s also compatible with a wide range of polymers and resins due to the many different types of light sources compatible with DLP technology.

With that said, here are five key tips and tricks to ensure your 3D printing experience is a smooth one.

- Select the right resin for your design. It may seem basic, but you’ll need resin to actually make something – it’s the material that is the basis for your 3D printed parts or objects. There are a variety of resin colors and mixtures available depending on your project needs.

- Choose something to print. Unless you have already created your own models in a CAD program from scratch, you’ll want to visit an online resource to download some pre-made models. Websites like Thingiverse are a good starting point.

- Start Simple. When you first start printing with an SLA printer, choose something with a solid base to ensure greater success. Your resin color choice can also be a factor. For example, clear resins can be easier to begin with because they generally require shorter exposure times which reduce the time it takes to get your first print.

- Prepare for clean up duty. Resin is sticky and can quickly make a mess, so have some isopropyl alcohol, a putty scraper, and gloves at the ready for the inevitable cleanup. A putty scraper is very effective at removing your models from the build head.

- Experiment and have fun! The possibilities with 3D printers are limited only by your imagination. Once you become familiar with your equipment, you’ll be able to make informed adjustments to settings like layer exposure time and number of burn-in layers to increase your build success rate. You may be surprised what a few small adjustments can do for your builds.

This is just the tip of the veritable 3D-printed-iceberg in terms of what it takes to have a successful printing experience. For more details, I encourage you to check out some of the great solutions and resources we have at TI, including 3D printing reference designs, training and videos, and technical documents. You can also read about how Autodesk created their Ember 3D printer and the types of questions they asked when first starting out.