-

Eight Things to Consider When Choosing Haptic Feedback – Part 1

Eight Things to Consider When Choosing Haptic Feedback – Part 1

Kelly Griffin

As integrated electronics begin to peak, the haptics industry is still in an early age of development. Many people interact with electronics and never think about the feedback transferred from the virtual world of electronics to their tactile senses. We tend to interact more often with electronics through sound. But this interaction is changing, and people want more discreet notifications over distracting ring tones. The vibrate setting on phones or wearable devices enables haptic feedback, but not all haptic feedback is the same.

To provide the most realistic experience, the haptic team at TI created an innovative generation of integrated haptic drivers including the DRV262x family. I will use the DRV2624 and DRV2625 devices as examples when explaining the features you should focus on when selecting your own haptic device. To provide the most realistic feedback using eccentric rotating masses (ERMs) or linear resonance actuators (LRAs), you will need a device that implements advanced haptic effects.

Overdrive, Auto-braking, and Sine and Square Outputs

Overdrive and auto-braking significantly improve the haptic experience. For those unfamiliar with these terms, overdrive overcomes the initial inertia required to quickly start an actuator by applying a voltage beyond the rated voltage but limited to a certain “overdrive clamp” voltage. Auto-braking reverses the phase or applies a negative drive voltage to an actuator while monitoring the back electromotive force (EMF) to quickly stop the motor.

When choosing a device, a designer of a mobile application would be interested in sharp braking using open-loop operation. Sharp braking would allow a designer to provide crisp feedback. The DRV262x family enables closed-loop auto-braking out of open-loop mode. This means if you decided to use the open-loop functionality, but still wanted fast braking, devices like the DRV2625 and DRV2624 enable quick braking by detecting a “stop bit” – switching to closed-loop mode quickly and implementing the auto-braking feature.

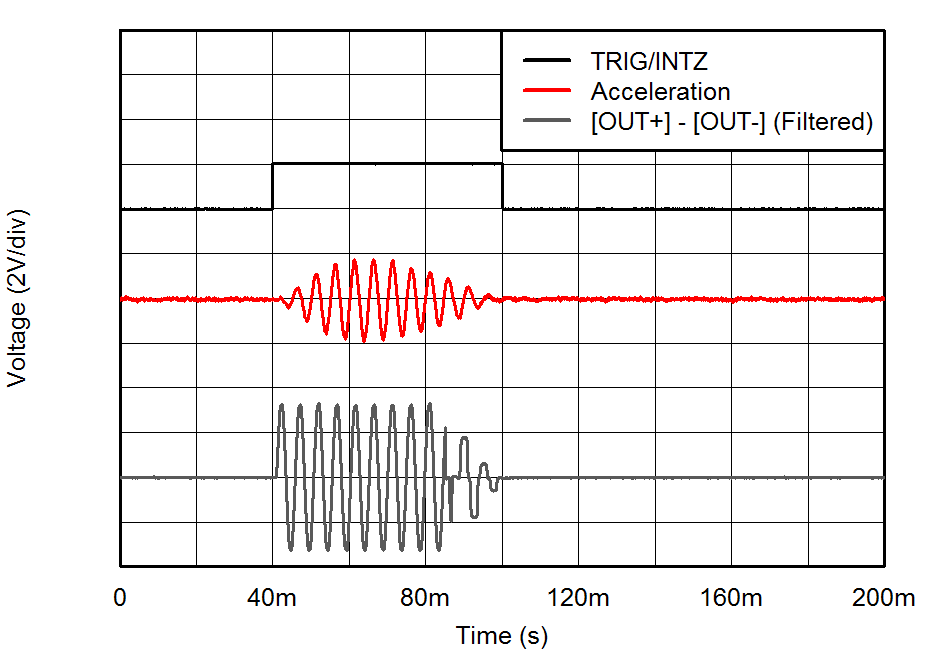

The newest generation of haptic drivers can switch between sine- and square-wave outputs in open-loop operation. Sometimes actuators respond better to either sine-wave outputs or square-wave outputs over other types of drive signals. You can test both types of signals on the actuator and select the most effective output, an examples is shown in Figure 1 and Figure 2. Flexibility is a key component of selecting a good haptic driver.

Figure 1 Example Square-wave

Output

Figure 1 Example Square-wave

Output Figure 2 Example Sine-wave

Output

Figure 2 Example Sine-wave

OutputOne-wire Interface

Developers often have to decide between implementing parts based on the number of pins available on their microcontroller unit (MCU). This is why we provide solutions based on one wire. There are two ways to implement the scheme. The first involves tying the NRST and TRIG pins together. Driving both of these pins high at the same time will almost instantly start an LRA (within 1ms). Likewise, pulling both pins low will put the part into shutdown. The second implementation ties the NRST, TRIG and VDD pins together, keeping in mind that the general purpose input/output (GPIO) you use will have to be able to supply the necessary current for operation. Pulling all three lines high at the same time will turn the DRV2624 or DRV2625 haptic driver on and start a haptic effect in less than 2ms. This allows you to implement a world-class haptic driver with a single GPIO.

Solution Size

All of these features sound great, but the chip must be large to integrate all of these features, right? Wrong! All of these advanced features are squeezed into one of the smallest packages of any haptic driver on the market. Both the DRV2624 and DRV2625 packages have a total surface area is 2.04mm2, which enables implementation into the mobile space as well as wearable devices.

These first five features are only a few of the recent advancements made in haptic drivers. Next week, I will discuss the final three things you should consider when making your haptic selection. In the meantime, log in and subscribe to Analog Wire to receive alerts through sound or vibration, your choice, when my colleagues and I post a blog. You’ll want to know when part two of this series posts.

Additional Resources

- Visit the haptic portal for more information.

- Read more blog posts on haptics.

- Learn more about haptics in automotive, industrial, mobile and other applications from TI’s solution guides.

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated