-

TAS2781 and TAS2783 Hybrid-Pro Boost Controller

TAS2781 and TAS2783 Hybrid-Pro Boost Controller

Abstract

The TAS2781 and TAS2783 devices are mono, digital input class-D audio amplifiers optimized for efficiently driving high peak power into small loudspeakers with integrated voltage and current sense. An on-chip digital-signal processor (DSP) supports Texas Instruments' SmartAmp speaker protection algorithm. The TAS2781 operates using time division multiplex (TDM), I2S, and I2C (or serial peripheral interface (SPI)) interfaces. The TAS2783 provides a flexible SoundWire 1.2 compatible peripheral interface for control and data, an I2C peripheral interface, and an I2S interface for digital audio data communication. The TAS2781 and TAS2783 have an extensive set of features that include the following:

- Integrated DSP for audio processing

- 23-V supply for class-D output stage

- Y-bridge multilevel supply architecture

- Hybrid-Pro external boost control algorithm

- Ultrasonic output support up to 40 kHz

This document provides guidelines for using the Hybrid-Pro feature in the TAS2781 and TAS2783 by giving an overview of the internal algorithm, external interface architecture, PurePath™ Console 3 (PPC3) software, and performance results. The high-efficiency class-D operation with Hybrid-Pro provides approximately 50% longer battery life, essential for portable speaker applications, compared to fixed-supply voltage designs.

Trademarks

PurePath™ is a trademark of Texas Instruments.

All trademarks are the property of their respective owners.

1 Introduction

Traditional audio amplifier systems consist of an audio amplifier and a boost converter with a constant output voltage to achieve the maximum power to be delivered to the speaker load.

Modern audio amplifiers with class-D architecture provide efficiencies higher than 90%. Higher efficiency results in lower power consumption and longer battery-life. This allows class-D amplifiers to be used for compact system designs across various applications like home theater, portable speaker, soundbar, car-audio, and so forth.

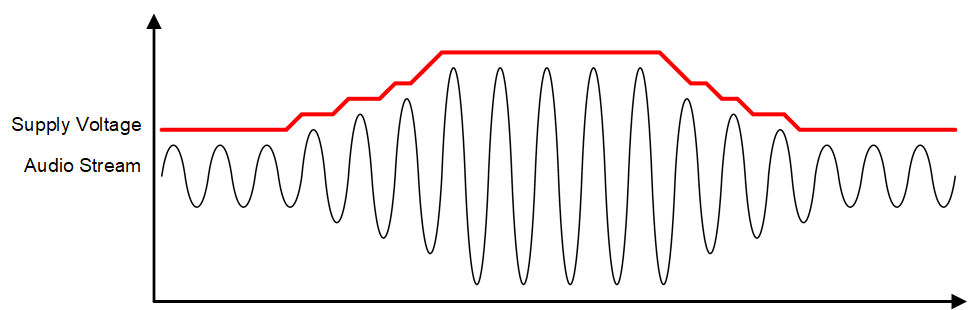

The dynamic nature of music, typically, needs maximum voltage for short moments, and only when the listener sets the system to maximum volume. Hence a fixed-voltage power supply is inefficient in most use cases due to larger inductors, MOSFETs, and copper area on the PCB to handle the increased thermal load. These system challenges can be solved with an envelope-tracking power-supply system. The audio signal is analyzed to determine the optimum power supply voltage for a given audio input. The power-supply voltage is adjusted by dynamically controlling the output voltage of the boost converter. The entire system operates to directly match the needs of the audio signal at all times instead of only maintaining the voltage required at the maximum power use-case. Power losses in the system are reduced and power efficiency and thermals improve significantly.

Figure 1-1 Envelope Tracking

Figure 1-1 Envelope TrackingIn a class-G system, the supply voltage for the class–D output is boosted when needed. The audio amplifier is able to monitor the input audio stream and determine the corresponding optimum output voltage for the amplifier. If the output voltage exceeds a certain threshold then the boost is enabled to provide additional headroom. In class-H amplifiers, the output voltage level of the boost converter for the amplifier has a more granular level. With this implementation there can be several possible supply voltages as shown in Figure 1-3. This enables the output to operate with just enough headroom to maintain low distortion while achieving higher output efficiency.

The integrated class-H controller, usually known as the Hybrid-Pro boost controller, of the TAS2781 and TAS2783 can track the envelope of the incoming audio stream and control the boost converter to adjust the power supply voltage for the audio amplifier. This envelope tracking algorithm looks ahead into the audio signal to detect a peak and prepare the boost converter to switch to a higher supply voltage. The Hybrid-Pro boost controller sends out a pulse-width modulation (PWM) signal, with duty cycle proportional to the peak, to the boost converter. The output from the audio amplifier has a programmable delay to allow the boost converter to settle to the voltage level. When the audio signal starts falling, the tracker holds the peak for a certain duration to prevent rapid voltage fluctuations. Finally, the Hybrid-Pro boost controller follows the falling audio signal using a decay envelope to enable the boost converter to switch to a lower headroom. Monitoring of the audio signal or external control of the boost converter from a microcontroller is not necessary.

2 Hybrid-Pro Boost Controller

The TAS2781 and TAS2783 (hereafter termed TAS278x when interchangeable in this application note) have an internal Hybrid-Pro algorithm allowing users to optimize the efficiency in the system by controlling the external power supply with just enough margin to provide high dynamic range with low distortion.

Features of Hybrid-Pro control:

- Hybrid-Pro control waveform is configurable as either 8 or 16 output voltage steps with 384-kHz or 192-kHz PWM, respectively, for external boost converter

- Configurable maximum 4-ms look-ahead audio signal delay for various bandwidth and load capacitance combinations of external boost converters in the system

- Low distortion output with optimum programmable peak hold time up to 8 ms

- Balances efficiency with envelope tracking by dynamically adjusting the audio signal trigger level and the output voltage step size of the external boost converter

The Hybrid-Pro boost controller generates a PWM signal at the PWM_CTRL pin with a duty cycle proportional to the peak voltage at the speaker. The signal is converted to an analog voltage to control boost converter feedback (FB) input using an external low-pass filter as shown in Figure 2-1 (see Section 3.1 for details).

By default, the PWM_CTRL pin is configured in an open drain. This configuration allows an easy implementation of a multichannel control loop using a common low-pass filter (LPF). Multiple TAS278x devices can be connected to the same LPF. One pullup resistor is needed between the common connection of the pins and IOVDD rail (see Figure 2-2).

When only one amplifier is driving the LPF, program the PWM_CTRL pin as a push-pull driver. This helps to improve efficiency and reduce one of the external components.