-

Designing the Elevators of the Future

Designing the Elevators of the Future

Kelvin Le THS

According to the United Nations Department of Economic and Social Affairs, two-thirds of the world’s population will live in cities by 2050. With a fast-growing trend toward urbanization, smart people-sensing technologies in buildings such as artificial intelligence, computer vision and people counting can help improve mobility, reduce inefficiency and potentially increase building values. In this blog post, I’ll explore how smart people-sensing technologies in elevator systems can help improve the passenger experience by reducing destination time.

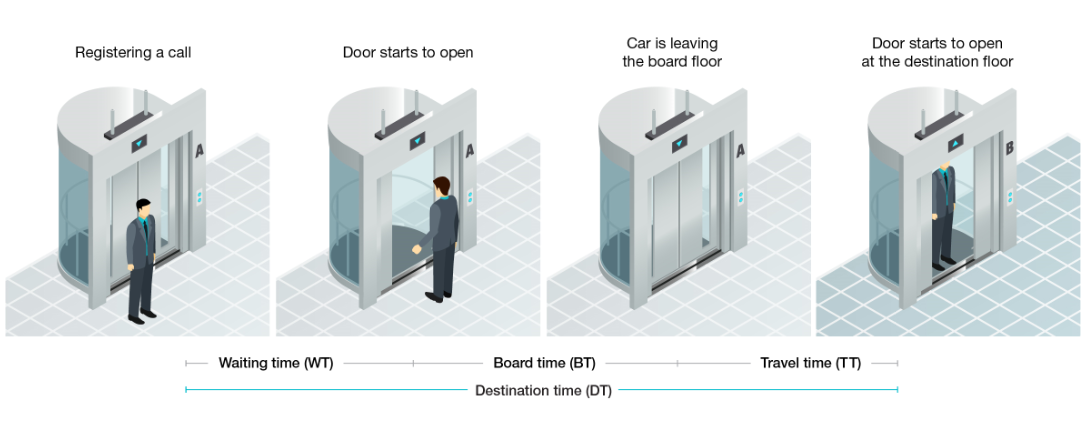

Figure 1 shows the three distinct time segments that make up destination time: wait time, board time and travel time.

Figure 1 Time segments of elevator

destination time

Figure 1 Time segments of elevator

destination timeOne of the key goals when designing modern elevator systems is to reduce the average destination time for all passengers. In a 16-floor commercial office building, for example, the average destination time is around 70 s and the average wait time is around 25 s – but that time will fluctuate based on time of day. During lunch, the destination time in office buildings tends to be longer than morning, since the traffic is going both ways as people enter and leave a building.

Modern elevator systems strive to reduce passenger destination time and increase the efficiency of how people move throughout a building. Smart elevator group control algorithms can help predict and manage people flow during rush hours, such as in the morning and during lunch. A full elevator stopping at a floor to pick up more passengers is not an efficient operation – for those both inside and outside the elevator. In another example, sending an elevator to an empty floor (when someone requests an elevator but walks away) is also not efficient.

| People tracking and, counting, and motion detection using mmWave sensors | |

|

Get started on your design today |

One way to address these challenges is by counting both those inside the elevator and those waiting outside the elevator in real time, which can enable efficient and dynamic group control algorithms. The ability to distinguish people waiting outside versus people just passing by the elevator is also important, as it will provide more accurate data for an elevator queue. Having smart people-detection capabilities (people counting and movement distinctions) enables the elevator group controller to prioritize elevator dispatch more efficiently, improving the passenger experience and lowering energy usage and operating costs.

TI’s industrial mmWave sensors for building automation enable the detection and tracking of people indoors up to 14 m away. TI mmWave sensors can be used for high-accuracy occupancy detection, where the position and velocity of people can trigger elevator systems upon a person entering an area of interest or moving in a particular direction. In addition, the elevator door operations can be augmented with mmWave sensors (keeping door open or closing during boarding time). TI mmWave sensors use onboard processing to reduce false detection by ignoring signatures of static objects that are not of concern (such as tables and boxes) and even dynamic objects such as plants and fans. The sensors can operate in challenging environments such as dazzling sunlight; nighttime; and low-visibility cases like smoke, fog and dust. With no camera or optical lenses, mmWave technology is also suitable for privacy-conscience applications.

There are many mmWave sensor examples, training videos and reference designs available from TI.

Additional Resources

- Learn more about designs for the elevator main control panel and elevator door operator drive control.

- Download these reference designs:

- Watch the TI Training video, “Automated doors with mmWave”