SBAA538A March 2022 – May 2024 TMAG5170 , TMAG5273

1

Introduction

Robotic mechanisms require a programmed response to setup and control behavior to accomplish a specific task. These tasks vary from mobile transport to stability controls or manufacturing and assembly jobs. The motion of the robot in every case is controlled through a motorized mechanism which can be driven directly or coupled to the system by some other means such as a gear box, belt, screw, or rack and pinion.

Figure 1 Robotics Mechanisms

Figure 1 Robotics MechanismsIn all cases, the spinning of the motor shaft is coupled to the system. In any application, understanding how the motor shaft position relates to the overall system behavior is critical for a number of reasons.

- Reliable position control for consistent system control

- Reduced risk of damage or injury to the system, nearby objects, and people

- Improved synchronization and sequencing of functions for faster response

These factors impact how well an autonomous mobile robot can guide itself about a warehouse floor or the accuracy and repeatability of a six-axis robotic arm performing assembly tasks.

While position information can be derived incrementally from sensors used to commutate the motor, a higher degree of precision is often necessary to produce consistent behavior. Angle encoding is commonly used to track the position of the motor shaft to provide the required precision.

Angle Encoding Designs

To measure the absolute angle of the motor shaft, an encoder must perform measurements on the shaft itself. Most robotics applications require absolute position information which is commonly obtained using magnetic sensing or optical encoding. To perform reliably, optical encoders require bulky enclosures to protect the sensor from dirt, dust, or other contaminants. Additionally, these designs must be mechanically coupled to the motor shaft and can become limited in operating speed.

Magnetic and inductive sensing are both able to work around both of these challenges. With a magnet attached to the motor shaft, the angular position can be determined by measuring the magnetic field. More information on this measurement is found in the Absolute Angle Measurements for Rotational Motion Using Hall-Effect Sensors application brief.

Magnetic Sensing

Standard Hall-effect magnetic sensors are one dimensional by nature. The Hall-effect measures a voltage differential in a current-carrying element caused by the Lorentz force. By nature, the applied field, the current, and the voltage is mutually orthogonal. As a result only one component of the three-dimensional magnetic field can be measured by a single device.

Figure 2 Hall-Effect

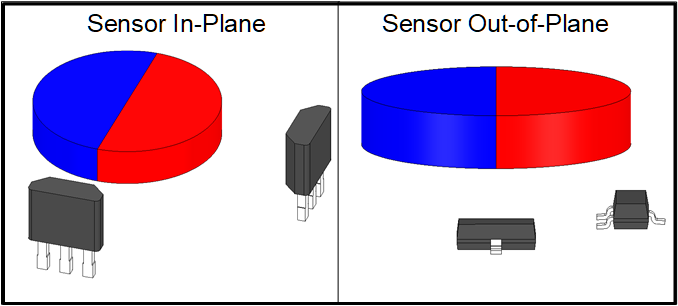

Figure 2 Hall-EffectTo effectively measure angle for a full 360 degree rotation with the arctangent function, two sensing elements separated by 90 degrees are required. The resulting arrangement using standard one-dimensional sensors is shown in One Dimensional Hall-Effect Sensor Placement

Figure 3 One Dimensional Hall-Effect Sensor Placement

Figure 3 One Dimensional Hall-Effect Sensor PlacementWhile this method to sense the position of the magnet does provide the required inputs, it requires physical separation of the two sensors about the rotating magnet. Each sensor must be carefully aligned to the magnet to achieve the highest quality input. Overcoming this challenge often requires careful assembly. Surface mount devices can potentially rotate as they self-align during solder reflow and through-hole components require a jig or spacers during assembly to ensure both consistent height and alignment. Even if ideal alignment is achieved during soldering, applied force to the device can bend the leads and produce a non-ideal alignment.

For these reasons, a monolithic 3D Hall-effect sensor, such as TMAG5170 , TMAG5273 and TMAG5173-Q1, are excellent options for robotics position encoders. This type of device is capable of measuring and reporting each of the individual components of the B-field vector, see Figure 4.

Figure 4 B-Field Vector

Figure 4 B-Field VectorWhen monitoring each component, the rotating magnet naturally provides inputs to the sensor with a phase difference of 90 degrees.

Figure 5 Example 3D Magnetic Input

Figure 5 Example 3D Magnetic InputWhen using a 3D Hall-effect sensor, the Hall elements used to measure the magnetic field are mutually orthogonal within the same die. As a result, small soldering mis-alignments are more forgiving when finding angular positions because the sensing elements always remain aligned to one another. Sensitivity matching is also improved when using sensors integrated into a single die as they experience similar conditions during manufacturing.

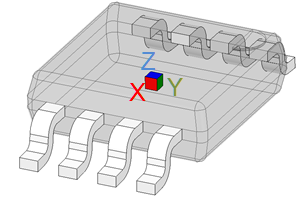

Figure 6 3D Hall-Effect Sensor

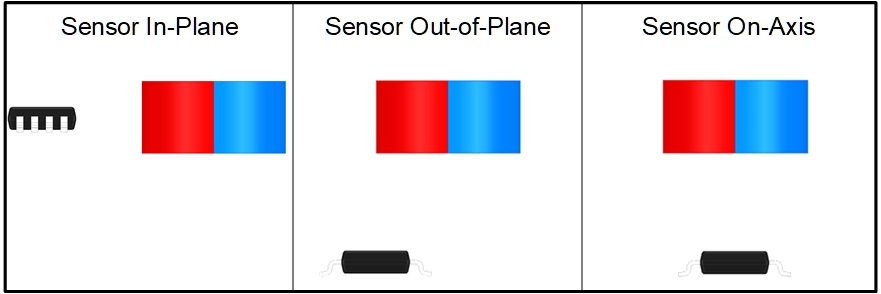

Figure 6 3D Hall-Effect SensorNow with only one package to align, the placement about the magnet is more flexible. Either a ring magnet mounted on the shaft through-hole or end of a standard cylindrical magnet can be used. The sensor is able to be placed conveniently for a compact encoding design anywhere within range of the magnet that is accessible.

Figure 7 3D Hall-Effect Sensor Placement

Figure 7 3D Hall-Effect Sensor PlacementAnother great benefit of this family of devices is the ability to send data back to the microcontroller over a digital interface. Interfering electrical noise is of less concern when transmitting over wire as the digital data is more difficult to corrupt. Cyclic redundancy check (CRC) provides confidence in signal integrity for all read operations. This allows for remote placement of the microcontroller as well, which offers improved versatility in mechanical design.

TMAG5170 also is capable of running self diagnostics during normal operation. These include checks for internal memory, VCC status, internal LDO status, output pin voltages, temperature, and other device functionality verifications. This feature provides real-time information regarding the state of the device to help guide system actions that can impact reliability or safety.

| Data Sheet | Characteristics | Design Considerations |

|---|---|---|

| DRV5055 Ratiometric Linear Hall Effect Sensor (DRV5055-Q1 Automotive Ratiometric Linear Hall Effect Sensor) | Commercial (Automotive) single axis bipolar linear Hall-effect sensor with analog output available in SOT-23 and TO-92 packages | One dimensional analog outputs are subject to electrical noise and calculations require microcontroller computations. Alignment is more difficult because two sensors are required. |

| TMAG5170 High-Precision 3D Linear Hall-Effect Sensor With SPI (TMAG5170-Q1 High-Precision 3D Linear Hall-Effect Sensor With SPI) | Commercial (Automotive) grade linear 3D Hall-effect position sensor with SPI available in 8-pin DGK package | Complete magnetic vector sensitivity. This device is able to track a wide range of magnet positions, though careful planning is still required to make sure all input conditions map to a unique position. |

| TMAG5273 Low-Power Linear 3D Hall-Effect Sensor With I2C Interface | Linear 3D Hall-effect position sensor with I2C interface available in 6 pin SOT-23 package | TMAG5170 has a tighter sensitivity tolerance and TMAG5273 operates over I2C |

TMAG5173-Q1 Automotive, high-precision, linear 3D Hall-effect sensor with I²C interface | Automotive, high-precision, linear 3D Hall-effect sensor with I²C interface available in 6 pin SOT-23 package | The TMAG5173-Q1 is a low-power linear 3D Hall-effect sensor With Systematic capability up to ASIL D and Hardware integrity up to ASIL B or SIL 2 |

| Name | Description |

|---|---|

| Angle Measurement with Multi-Axis Hall-Effect Sensors | Application note detailing angle measurements using TMAG5170 |

| Absolute Angle Measurements for Rotational Motion Using Hall-Effect Sensors | Application brief introducing angle measurement using Hall-effect magnetic sensors |

| TIDA-060040 | Reference design and test results demonstrating angular accuracy and calibration in various alignment configurations using both 1D and 3D Hall-effect sensors. |

| TMAG5170UEVM | GUI and attachments incorporate angle measurement using a precise three dimensional linear Hall-effect sensor |

| TMAG5273EVM | GUI and attachments incorporate angle measurement using a three dimensional linear Hall-effect sensor |

| DRV5055EVM | EVM incorporates a digital display with various sensitivities aligned linearly along a ruler face. |

| TI Precision Labs - Magnetic Sensors | A helpful video series describing the Hall effect and how the Hall effect is used in various applications |

| TMAG5173EVM | Easy-to-use platform to evaluate the main features and performance of the TMAG5173-Q1 device, which is a linear 3D Hall-effect sensor. EVM incorporate one magnet and a TMAG5173-Q1 daughter board. |