SBOA598 June 2024 OPT3007 , OPT4001 , OPT4001-Q1

Introduction

Texas Instruments introduced the first IC in a wafer chip scale package, coined PicoStar, in 2009. PicoStar has led to numerous different products being released to fit into space constrained environments while maintaining the high level of performance customers are used to. With this proprietary packaging technology being offered company-wide, Texas Instruments released the first ambient light sensor with a PicoStar option in 2016 with the OPT3006, followed with the release of OPT3007 and OPT4001. There are many reasons to incorporate a light sensor with these small dimensions into your industrial, automotive, and commercial products. This application brief discusses the advantages and use cases of using a TI light sensor in the PicoStar package.

Market Trend

In addition to the move towards sleeker displays in the personal electronics and industrial markets, the automotive industry has seen a spike in the number of displays incorporated across the vehicle, including the head unit, center information display, passenger display, and rear seat entertainment. Utilizing an automotive grade light sensor in the PicoStar package from TI allows for more flexibility when designing modern dashboards and infotainment systems. In modern vehicles, there has been a trend of having multiple displays across the dash or one continuous display that stretches from the driver to the passenger. With displays such as these, having a localized sensor is crucial for the user experience making TI's automotive grade light sensors in the PicoStar package an excellent choice for a design.

Small Size

The most obvious advantage when utilizing a PicoStar device is the small size in both the XY and Z dimensions. The YMF package (OPT3006, OPT3007) measures 0.856mm x 0.946mm and the YMN package (OPT4001) measures 1.05mm x 0.84mm length by width, both providing flexibility for small areas. This is extremely important with light sensors due to the tight layout constraints of modern day displays. Most modern monitors, phones, tablets, and laptops have extremely thin or nonexistent bezels,limiting where a light sensor can be placed. For these applications, light sensors are quite important and the PicoStar package is able to fit in between the thin gaps between adjacent displays.

The height of the package is another important dimension that must not be overlooked. The PicoStar package comes at a height of 0.22mm, making this package the thinnest light sensor in the industry. In addition to XY space on a board, the height is important due to volumetric space constraints near the display due to illumination boards for the LCD panel. Light sensors that come in the PicoStar package require bottom facing implementation to be placed on a flex PCB, allowing for the device to be placed closer to the display and fit into small spaces.

Bottom Facing Assembly

Another advantage to highlight is a part of the unique assembly that this device requires. TI’s PicoStar light sensors have a bottom facing light sensitive area as opposed to the traditional top facing. The sensor is the only bottom facing light sensor in production as of publication. This feature allows the flex PCB to be directly attached to the cover glass, maintaing high base level performance. Additionally, this helps avoid the extra cost of adding optical shields and shrouds, reducing the overall system level cost.

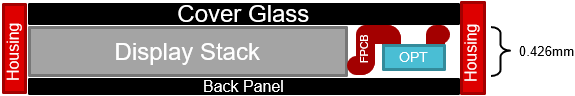

Figure 1 and Figure 2 illustrate how the PicoStar package looks when placed in a system, showing both the side view and the top view.

Figure 1 shows (not to scale) how TI's PicoStar package light sensor (OPT) is placed in relation to the cover glass, display stack, back panel, and housing. The sensor is connected to the display stack using a flex PCB (FPCB) with a hole cut to expose the sensor area. The height of the flex PCB and the sensor combine to approximately 0.426mm.

Figure 1 PicoStar Side View

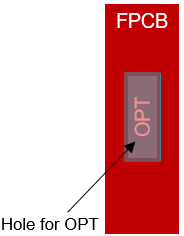

Figure 1 PicoStar Side ViewFigure 2 shows how the OPT sensor looks from the top view when attached to the bottom of the flex PCB. There must be a cut out in the flex PCB so that light can fall directly on the sensor area through the cover glass. The hole in the flex PCB can be either circular, rectangular (as shown), or cross shaped, depending on your system needs.

Figure 2 PicoStar Top View

Figure 2 PicoStar Top ViewImproved Resolution

TI’s OPT4001 in the PicoStar package offers better resolution than the SOT and QFN counterparts, with sensitivity as low as 312.5µLux compared to 400µLux for the other packages. This low sensitivity enables the device to better measure the light in the environment while being placed under darker cover glass. In addition to the resolution, overall performance of the device is better due to having up to 10x lower power and 4 to 12 more bits of dynamic range, optimized for stringent requirements. The table below details the differences between TI’s package offerings for the OPT4001:

| DNP | DTS | YMN (PicoStar) | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | 2mm x 2mm x 0.65mm | 2.1mm x 1.9mm x 0.6mm | 0.84mm x 1.05mm x 0.226mm | ||||||||||||||||||

| Pin Count | 6 | 8 | 4 | ||||||||||||||||||

| Sensor Area | Top | Top | Bottom | ||||||||||||||||||

| Resolution |

|

|

|

||||||||||||||||||

| Dynamic Range | 107kLux Saturation | 117kLux Saturation | 83kLux Saturation | ||||||||||||||||||

| Temperature Range | -40C to 105C | -40C to 105C | -40C to 125C |

Conclusion

In summary, Texas Instruments PicoStar packaged light sensors offer some advantages for space constrained system designs across industrial, automotive, and commercial applications. The PicoStar package is currently offered for the OPT3007, OPT4001, and OPT4001-Q1 with more releases expected soon. TI offers more information about our Light Sensors and the PicoStar package in the TI Precision Labs video series. Data sheets, application notes, and more about TI’s light sensing portfolio can be found on the light sensors home page.