During SEL characterization, the device was heated

using forced hot air, maintaining device temperature at 125°C. A FLIR (FLIR ONE Pro

LT) thermal camera was used to validate die temperature to make sure the device was

being accurately heated (see Figure 3-5). The species used for SEL testing was a

Xenon (129Xe) ion at a linac energy of 25 MeV / µ with an

angle-of-incidence of 0° for an LETEFF of 43 MeV-cm2 / mg. A

fluence of approximately 1 × 107 ions / cm2 were used for the

runs.

The three devices were powered up and exposed to

the heavy-ions using the maximum recommended supply voltage of 5.5 V with a National

Instruments PXI Chassis PXIe-1085 and a 5-V, 1 MHz square wave input using a

Tektronix AFG3102 function generator. The run duration to achieve this fluence was

approximately two minutes. As listed in Table 5-1, no SEL events were observed during the nine runs, which indicates that the

SN54SC245-SEP is SEL-free. Figure 5-1, Figure 5-2 , and Figure 5-3 show the plot of current versus time for runs one, four, and seven,

respectively.

Table 5-1 Summary of SN54SC245-SEP Test Conditions and Results| Run Number | Unit Number | Distance (mm) | Temperature

(°C) | Ion | Angle | FLUX

(ions × cm2 / mg) | Fluence

(Number of ions) | LETEFF

(MeV × cm2 / mg) | Did an SEL event occur? |

|---|

| 1 | 1 | 70 | 121 | Xe | 0° | 1.00E + 05 | 1.00E + 07 | 43 | No |

| 2 | 1 | 70 | 121 | Xe | 0° | 1.00E + 05 | 1.00E + 07 | 43 | No |

| 3 | 1 | 70 | 121 | Xe | 0° | 1.00E + 05 | 1.00E + 07 | 43 | No |

| 4 | 2 | 70 | 124 | Xe | 0° | 1.00E + 05 | 1.00E + 07 | 43 | No |

| 5 | 2 | 70 | 124 | Xe | 0° | 1.00E + 05 | 1.00E + 07 | 43 | No |

| 6 | 2 | 70 | 124 | Xe | 0° | 1.00E + 05 | 1.00E + 07 | 43 | No |

| 7 | 3 | 70 | 126 | Xe | 0° | 1.00E + 05 | 1.00E + 07 | 43 | No |

| 8 | 3 | 70 | 126 | Xe | 0° | 1.00E + 05 | 1.00E + 07 | 43 | No |

| 9 | 3 | 70 | 126 | Xe | 0° | 1.00E + 05 | 1.00E + 07 | 43 | No |

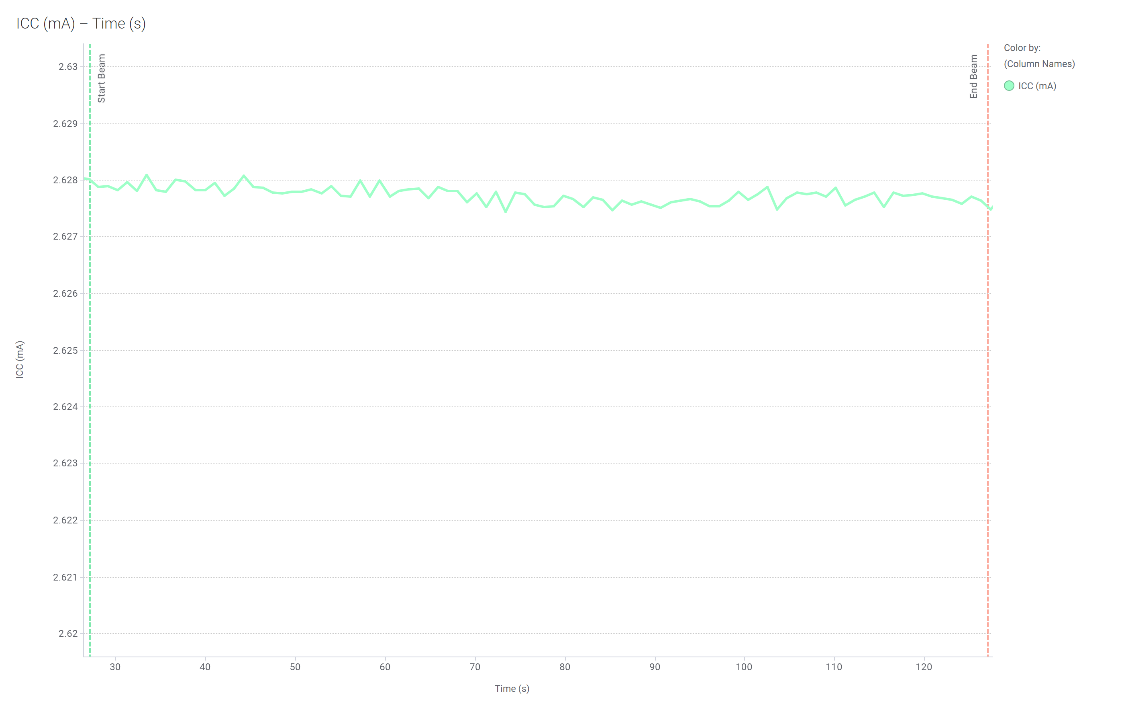

Figure 5-1 Current versus Time for Run

Number 1 of the SN54SC245-SEP at T = 125°C

Figure 5-1 Current versus Time for Run

Number 1 of the SN54SC245-SEP at T = 125°C

No SEL events were observed, which indicates that

the SN54SC245-SEP is SEL-immune at LETEFF = 43 MeV-cm2 / mg

and T = 125°C. Using the MFTF method described in

SN54SC245-SEP Single-Event Latch-Up (SEL) Radiation Report

SN54SC245-SEP Single-Event Latch-Up (SEL) Radiation Report

SN54SC245-SEP Single-Event Latch-Up (SEL) Radiation Report

SN54SC245-SEP Single-Event Latch-Up (SEL) Radiation Report

SN54SC245-SEP Single-Event Latch-Up (SEL) Radiation Report

Table of Contents

Table of Contents

Trademarks

Trademarks

Overview

Overview

Single-Event Effects (SEE) Mechanisms

Single-Event Effects (SEE) Mechanisms

Test Device and Test Board Information

Test Device and Test Board Information

Irradiation Facility and Setup

Irradiation Facility and Setup

Results

Results

SEL Results

SEL Results

Event Rate Calculations

Event Rate Calculations

Summary

Summary

References

References

IMPORTANT NOTICE AND DISCLAIMER

IMPORTANT NOTICE AND DISCLAIMER

SN54SC245-SEP Single-Event Latch-Up (SEL) Radiation Report

SN54SC245-SEP Single-Event Latch-Up (SEL) Radiation Report

SN54SC245-SEP Single-Event Latch-Up (SEL) Radiation Report

The purpose of this study is to characterize the

effects of heavy-ion irradiation on the single-event latch-up (SEL) performance

of the SN54SC245-SEP, 1.2 V to 5.5 V octal bus transceiver. Heavy-ions with an

LETEFF of 43 MeV-cm2 / mg were used to irradiate three

production devices with a fluence of 1 × 107 ions / cm2.

The results demonstrate that the SN54SC245-SEP is SEL-free up to

LETEFF = 43 MeV-cm2 / mg as 125°C.

SN54SC245-SEP Single-Event Latch-Up (SEL) Radiation Report

The purpose of this study is to characterize the

effects of heavy-ion irradiation on the single-event latch-up (SEL) performance

of the SN54SC245-SEP, 1.2 V to 5.5 V octal bus transceiver. Heavy-ions with an

LETEFF of 43 MeV-cm2 / mg were used to irradiate three

production devices with a fluence of 1 × 107 ions / cm2.

The results demonstrate that the SN54SC245-SEP is SEL-free up to

LETEFF = 43 MeV-cm2 / mg as 125°C.

The purpose of this study is to characterize the

effects of heavy-ion irradiation on the single-event latch-up (SEL) performance

of the SN54SC245-SEP, 1.2 V to 5.5 V octal bus transceiver. Heavy-ions with an

LETEFF of 43 MeV-cm2 / mg were used to irradiate three

production devices with a fluence of 1 × 107 ions / cm2.

The results demonstrate that the SN54SC245-SEP is SEL-free up to

LETEFF = 43 MeV-cm2 / mg as 125°C.

The purpose of this study is to characterize the

effects of heavy-ion irradiation on the single-event latch-up (SEL) performance

of the SN54SC245-SEP, 1.2 V to 5.5 V octal bus transceiver. Heavy-ions with an

LETEFF of 43 MeV-cm2 / mg were used to irradiate three

production devices with a fluence of 1 × 107 ions / cm2.

The results demonstrate that the SN54SC245-SEP is SEL-free up to

LETEFF = 43 MeV-cm2 / mg as 125°C.

The purpose of this study is to characterize the

effects of heavy-ion irradiation on the single-event latch-up (SEL) performance

of the SN54SC245-SEP, 1.2 V to 5.5 V octal bus transceiver. Heavy-ions with an

LETEFF of 43 MeV-cm2 / mg were used to irradiate three

production devices with a fluence of 1 × 107 ions / cm2.

The results demonstrate that the SN54SC245-SEP is SEL-free up to

LETEFF = 43 MeV-cm2 / mg as 125°C.EFF272EFF2

Table of Contents

yes

yes

yes

Table of Contents

yes

yes

yes

yes

yes

yes

yesyesyes

Trademarks

Trademarks

Overview

The SN54SC245-SEP is a radiation-tolerant, 1.2 V

to 5.5 V, octal bus transceivers with tri-state outputs. All eight channels are

controlled by the direction (DIR) pin and output enable (OE)

pin. The output enable (OE) controls all outputs in the device.

When the OE pin is in the low state, the appropriate outputs

are enabled as determined by the direction (DIR) pin . When the

OE pin is in the high state, all outputs of the device are

disabled. All disabled outputs are placed into the high-impedance

state.

See the SN54SC245-SEP product

page for more details. Overview Information lists device information.

Overview Information

Description

Device

Information

TI part number

SN54SC245-SEP

MLS number

SN54SC245MPWTSEP

Device function

Radiation-tolerant, 1.2-V to 5.5-V, octal bus

transceivers with tri-state outputs

Technology

LBC9

Exposure facility

Facility for Rare Isotope Beams (FRIB) at Michigan

State University (FRIB Single Event Effects [FSEE] Facility)

Heavy ion fluence per

run

1 × 107

ions / cm2

Irradiation temperature

125°C (for SEL testing)

Overview

The SN54SC245-SEP is a radiation-tolerant, 1.2 V

to 5.5 V, octal bus transceivers with tri-state outputs. All eight channels are

controlled by the direction (DIR) pin and output enable (OE)

pin. The output enable (OE) controls all outputs in the device.

When the OE pin is in the low state, the appropriate outputs

are enabled as determined by the direction (DIR) pin . When the

OE pin is in the high state, all outputs of the device are

disabled. All disabled outputs are placed into the high-impedance

state.

See the SN54SC245-SEP product

page for more details. Overview Information lists device information.

Overview Information

Description

Device

Information

TI part number

SN54SC245-SEP

MLS number

SN54SC245MPWTSEP

Device function

Radiation-tolerant, 1.2-V to 5.5-V, octal bus

transceivers with tri-state outputs

Technology

LBC9

Exposure facility

Facility for Rare Isotope Beams (FRIB) at Michigan

State University (FRIB Single Event Effects [FSEE] Facility)

Heavy ion fluence per

run

1 × 107

ions / cm2

Irradiation temperature

125°C (for SEL testing)

The SN54SC245-SEP is a radiation-tolerant, 1.2 V

to 5.5 V, octal bus transceivers with tri-state outputs. All eight channels are

controlled by the direction (DIR) pin and output enable (OE)

pin. The output enable (OE) controls all outputs in the device.

When the OE pin is in the low state, the appropriate outputs

are enabled as determined by the direction (DIR) pin . When the

OE pin is in the high state, all outputs of the device are

disabled. All disabled outputs are placed into the high-impedance

state.

See the SN54SC245-SEP product

page for more details. Overview Information lists device information.

Overview Information

Description

Device

Information

TI part number

SN54SC245-SEP

MLS number

SN54SC245MPWTSEP

Device function

Radiation-tolerant, 1.2-V to 5.5-V, octal bus

transceivers with tri-state outputs

Technology

LBC9

Exposure facility

Facility for Rare Isotope Beams (FRIB) at Michigan

State University (FRIB Single Event Effects [FSEE] Facility)

Heavy ion fluence per

run

1 × 107

ions / cm2

Irradiation temperature

125°C (for SEL testing)

The SN54SC245-SEP is a radiation-tolerant, 1.2 V

to 5.5 V, octal bus transceivers with tri-state outputs. All eight channels are

controlled by the direction (DIR) pin and output enable (OE)

pin. The output enable (OE) controls all outputs in the device.

When the OE pin is in the low state, the appropriate outputs

are enabled as determined by the direction (DIR) pin . When the

OE pin is in the high state, all outputs of the device are

disabled. All disabled outputs are placed into the high-impedance

state.OEOEOEOESee the SN54SC245-SEP product

page for more details. Overview Information lists device information.product

pageOverview Information

Overview Information

Description

Device

Information

TI part number

SN54SC245-SEP

MLS number

SN54SC245MPWTSEP

Device function

Radiation-tolerant, 1.2-V to 5.5-V, octal bus

transceivers with tri-state outputs

Technology

LBC9

Exposure facility

Facility for Rare Isotope Beams (FRIB) at Michigan

State University (FRIB Single Event Effects [FSEE] Facility)

Heavy ion fluence per

run

1 × 107

ions / cm2

Irradiation temperature

125°C (for SEL testing)

Overview Information

Description

Device

Information

TI part number

SN54SC245-SEP

MLS number

SN54SC245MPWTSEP

Device function

Radiation-tolerant, 1.2-V to 5.5-V, octal bus

transceivers with tri-state outputs

Technology

LBC9

Exposure facility

Facility for Rare Isotope Beams (FRIB) at Michigan

State University (FRIB Single Event Effects [FSEE] Facility)

Heavy ion fluence per

run

1 × 107

ions / cm2

Irradiation temperature

125°C (for SEL testing)

Description

Device

Information

Description

Device

Information

DescriptionDevice

Information

TI part number

SN54SC245-SEP

MLS number

SN54SC245MPWTSEP

Device function

Radiation-tolerant, 1.2-V to 5.5-V, octal bus

transceivers with tri-state outputs

Technology

LBC9

Exposure facility

Facility for Rare Isotope Beams (FRIB) at Michigan

State University (FRIB Single Event Effects [FSEE] Facility)

Heavy ion fluence per

run

1 × 107

ions / cm2

Irradiation temperature

125°C (for SEL testing)

TI part number

SN54SC245-SEP

TI part numberSN54SC245-SEP

MLS number

SN54SC245MPWTSEP

MLS numberSN54SC245MPWTSEP

Device function

Radiation-tolerant, 1.2-V to 5.5-V, octal bus

transceivers with tri-state outputs

Device functionRadiation-tolerant, 1.2-V to 5.5-V, octal bus

transceivers with tri-state outputs

Technology

LBC9

TechnologyLBC9

Exposure facility

Facility for Rare Isotope Beams (FRIB) at Michigan

State University (FRIB Single Event Effects [FSEE] Facility)

Exposure facilityFacility for Rare Isotope Beams (FRIB) at Michigan

State University (FRIB Single Event Effects [FSEE] Facility)

Heavy ion fluence per

run

1 × 107

ions / cm2

Heavy ion fluence per

run1 × 107

ions / cm2

72

Irradiation temperature

125°C (for SEL testing)

Irradiation temperature125°C (for SEL testing)

Single-Event Effects (SEE) Mechanisms

The primary single-event effect

(SEE) event of interest in the SN54SC245-SEP is the destructive single-event latch-up.

From a risk or impact perspective, the occurrence of an SEL is potentially the most

destructive SEE event and the biggest concern for space applications. In mixed

technologies such as the Linear BiCMOS (LBC9) process used for SN54SC245-SEP, the CMOS

circuitry introduces a potential SEL susceptibility. SEL can occur if excess current

injection caused by the passage of an energetic ion is high enough to trigger the

formation of a parasitic cross-coupled PNP and NPN bipolar structure (formed between the

p-substrate and n-well and n+ and p+ contacts). The parasitic bipolar structure

initiated by a single-event creates a high-conductance path (inducing a steady-state

current that is typically orders-of-magnitude higher than the normal operating current)

between power and ground that persists (is latched) until power is removed or until the

device is destroyed by the high-current state. The process modifications applied for

SEL-mitigation were sufficient, as the SN54SC245-SEP did not exhibit SEL with heavy-ions

up to an LETEFF of 43 MeV-cm2 / mg at a fluence of 1 ×

107 ions / cm2 and a chip temperature of 125°C.

Functional Block Diagram of

the SN54SC245-SEP

Single-Event Effects (SEE) Mechanisms

The primary single-event effect

(SEE) event of interest in the SN54SC245-SEP is the destructive single-event latch-up.

From a risk or impact perspective, the occurrence of an SEL is potentially the most

destructive SEE event and the biggest concern for space applications. In mixed

technologies such as the Linear BiCMOS (LBC9) process used for SN54SC245-SEP, the CMOS

circuitry introduces a potential SEL susceptibility. SEL can occur if excess current

injection caused by the passage of an energetic ion is high enough to trigger the

formation of a parasitic cross-coupled PNP and NPN bipolar structure (formed between the

p-substrate and n-well and n+ and p+ contacts). The parasitic bipolar structure

initiated by a single-event creates a high-conductance path (inducing a steady-state

current that is typically orders-of-magnitude higher than the normal operating current)

between power and ground that persists (is latched) until power is removed or until the

device is destroyed by the high-current state. The process modifications applied for

SEL-mitigation were sufficient, as the SN54SC245-SEP did not exhibit SEL with heavy-ions

up to an LETEFF of 43 MeV-cm2 / mg at a fluence of 1 ×

107 ions / cm2 and a chip temperature of 125°C.

Functional Block Diagram of

the SN54SC245-SEP

The primary single-event effect

(SEE) event of interest in the SN54SC245-SEP is the destructive single-event latch-up.

From a risk or impact perspective, the occurrence of an SEL is potentially the most

destructive SEE event and the biggest concern for space applications. In mixed

technologies such as the Linear BiCMOS (LBC9) process used for SN54SC245-SEP, the CMOS

circuitry introduces a potential SEL susceptibility. SEL can occur if excess current

injection caused by the passage of an energetic ion is high enough to trigger the

formation of a parasitic cross-coupled PNP and NPN bipolar structure (formed between the

p-substrate and n-well and n+ and p+ contacts). The parasitic bipolar structure

initiated by a single-event creates a high-conductance path (inducing a steady-state

current that is typically orders-of-magnitude higher than the normal operating current)

between power and ground that persists (is latched) until power is removed or until the

device is destroyed by the high-current state. The process modifications applied for

SEL-mitigation were sufficient, as the SN54SC245-SEP did not exhibit SEL with heavy-ions

up to an LETEFF of 43 MeV-cm2 / mg at a fluence of 1 ×

107 ions / cm2 and a chip temperature of 125°C.

Functional Block Diagram of

the SN54SC245-SEP

EFF272

Functional Block Diagram of

the SN54SC245-SEP

Functional Block Diagram of

the SN54SC245-SEP

Test Device and Test Board Information

The SN54SC245-SEP is a packaged 20-pin, TSSOP

plastic package as shown in the pinout diagram in . shows the device with the package cap decapped to reveal the die for heavy ion

testing. shows the evaluation board used for radiation testing. shows the

bias diagram used for Single-Event Latch-up (SEL) testing.

SN54SC245-SEP Pinout

Diagram

SN54SC245-SEP with

Decapped Package

SN54SC245-SEP Evaluation

Board (Top View)

SN54SC245-SEP SEL Bias

Diagram

SN54SC245-SEP Thermal Image

for SEL

Test Device and Test Board Information

The SN54SC245-SEP is a packaged 20-pin, TSSOP

plastic package as shown in the pinout diagram in . shows the device with the package cap decapped to reveal the die for heavy ion

testing. shows the evaluation board used for radiation testing. shows the

bias diagram used for Single-Event Latch-up (SEL) testing.

SN54SC245-SEP Pinout

Diagram

SN54SC245-SEP with

Decapped Package

SN54SC245-SEP Evaluation

Board (Top View)

SN54SC245-SEP SEL Bias

Diagram

SN54SC245-SEP Thermal Image

for SEL

The SN54SC245-SEP is a packaged 20-pin, TSSOP

plastic package as shown in the pinout diagram in . shows the device with the package cap decapped to reveal the die for heavy ion

testing. shows the evaluation board used for radiation testing. shows the

bias diagram used for Single-Event Latch-up (SEL) testing.

SN54SC245-SEP Pinout

Diagram

SN54SC245-SEP with

Decapped Package

SN54SC245-SEP Evaluation

Board (Top View)

SN54SC245-SEP SEL Bias

Diagram

SN54SC245-SEP Thermal Image

for SEL

The SN54SC245-SEP is a packaged 20-pin, TSSOP

plastic package as shown in the pinout diagram in . shows the device with the package cap decapped to reveal the die for heavy ion

testing. shows the evaluation board used for radiation testing. shows the

bias diagram used for Single-Event Latch-up (SEL) testing.

SN54SC245-SEP Pinout

Diagram

SN54SC245-SEP with

Decapped Package

SN54SC245-SEP Pinout

Diagram

SN54SC245-SEP Pinout

Diagram

SN54SC245-SEP with

Decapped Package

SN54SC245-SEP with

Decapped Package

SN54SC245-SEP Evaluation

Board (Top View)

SN54SC245-SEP SEL Bias

Diagram

SN54SC245-SEP Evaluation

Board (Top View)

SN54SC245-SEP Evaluation

Board (Top View)

SN54SC245-SEP SEL Bias

Diagram

SN54SC245-SEP SEL Bias

Diagram

SN54SC245-SEP Thermal Image

for SEL

SN54SC245-SEP Thermal Image

for SEL

Irradiation Facility and Setup

The heavy ion species used for the SEE studies on

this product were provided and delivered by the Facility for Rare Isotope Beams

(FRIB) at Michigan State University – FRIB Single Event Effects (FSEE) Facility’s

linear accelerator. The FSEE Facility has a dedicated beamline built on the FRIB

linac infrastructure with a user experimental station at the end of the FSEE

beamline. Ion beams are delivered with high uniformity over a 1-inch diameter

exposure area using a thin vacuum window. For this study, ion flux of 105

ions / s-cm2 was used to provide heavy ion fluence of 1 × 107

ions / cm2 using 129Xe ion at a linac energy of 25 MeV / µ.

Ion beam non-uniformity for all tests was 6.7%.

shows one of the three SN54SC245-SEP test board used for experiments at the MSU

FSEE facility. The in-air gap between the device and the ion beam port window was

maintained at 70 mm for all runs.

SN54SC245-SEP Evaluation Board

at the MSU FRIB Facility

Irradiation Facility and Setup

The heavy ion species used for the SEE studies on

this product were provided and delivered by the Facility for Rare Isotope Beams

(FRIB) at Michigan State University – FRIB Single Event Effects (FSEE) Facility’s

linear accelerator. The FSEE Facility has a dedicated beamline built on the FRIB

linac infrastructure with a user experimental station at the end of the FSEE

beamline. Ion beams are delivered with high uniformity over a 1-inch diameter

exposure area using a thin vacuum window. For this study, ion flux of 105

ions / s-cm2 was used to provide heavy ion fluence of 1 × 107

ions / cm2 using 129Xe ion at a linac energy of 25 MeV / µ.

Ion beam non-uniformity for all tests was 6.7%.

shows one of the three SN54SC245-SEP test board used for experiments at the MSU

FSEE facility. The in-air gap between the device and the ion beam port window was

maintained at 70 mm for all runs.

SN54SC245-SEP Evaluation Board

at the MSU FRIB Facility

The heavy ion species used for the SEE studies on

this product were provided and delivered by the Facility for Rare Isotope Beams

(FRIB) at Michigan State University – FRIB Single Event Effects (FSEE) Facility’s

linear accelerator. The FSEE Facility has a dedicated beamline built on the FRIB

linac infrastructure with a user experimental station at the end of the FSEE

beamline. Ion beams are delivered with high uniformity over a 1-inch diameter

exposure area using a thin vacuum window. For this study, ion flux of 105

ions / s-cm2 was used to provide heavy ion fluence of 1 × 107

ions / cm2 using 129Xe ion at a linac energy of 25 MeV / µ.

Ion beam non-uniformity for all tests was 6.7%.

shows one of the three SN54SC245-SEP test board used for experiments at the MSU

FSEE facility. The in-air gap between the device and the ion beam port window was

maintained at 70 mm for all runs.

SN54SC245-SEP Evaluation Board

at the MSU FRIB Facility

The heavy ion species used for the SEE studies on

this product were provided and delivered by the Facility for Rare Isotope Beams

(FRIB) at Michigan State University – FRIB Single Event Effects (FSEE) Facility’s

linear accelerator. The FSEE Facility has a dedicated beamline built on the FRIB

linac infrastructure with a user experimental station at the end of the FSEE

beamline. Ion beams are delivered with high uniformity over a 1-inch diameter

exposure area using a thin vacuum window. For this study, ion flux of 105

ions / s-cm2 was used to provide heavy ion fluence of 1 × 107

ions / cm2 using 129Xe ion at a linac energy of 25 MeV / µ.

Ion beam non-uniformity for all tests was 6.7%.5272129

shows one of the three SN54SC245-SEP test board used for experiments at the MSU

FSEE facility. The in-air gap between the device and the ion beam port window was

maintained at 70 mm for all runs.

SN54SC245-SEP Evaluation Board

at the MSU FRIB Facility

SN54SC245-SEP Evaluation Board

at the MSU FRIB Facility

Results

SEL Results

During SEL characterization, the device was heated

using forced hot air, maintaining device temperature at 125°C. A FLIR (FLIR ONE Pro

LT) thermal camera was used to validate die temperature to make sure the device was

being accurately heated (see Figure 3-5). The species used for SEL testing was a

Xenon (129Xe) ion at a linac energy of 25 MeV / µ with an

angle-of-incidence of 0° for an LETEFF of 43 MeV-cm2 / mg. A

fluence of approximately 1 × 107 ions / cm2 were used for the

runs.

The three devices were powered up and exposed to

the heavy-ions using the maximum recommended supply voltage of 5.5 V with a National

Instruments PXI Chassis PXIe-1085 and a 5-V, 1 MHz square wave input using a

Tektronix AFG3102 function generator. The run duration to achieve this fluence was

approximately two minutes. As listed in , no SEL events were observed during the nine runs, which indicates that the

SN54SC245-SEP is SEL-free. , , and show the plot of current versus time for runs one, four, and seven,

respectively.

Summary of SN54SC245-SEP Test Conditions and Results

Run Number

Unit Number

Distance (mm)

Temperature (°C)

Ion

Angle

FLUX (ions × cm2 / mg)

Fluence (Number of ions)

LETEFF

(MeV × cm2 / mg)

Did an SEL event occur?

1

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

2

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

3

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

4

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

5

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

6

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

7

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

8

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

9

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

Current versus Time for Run

Number 1 of the SN54SC245-SEP at T = 125°C

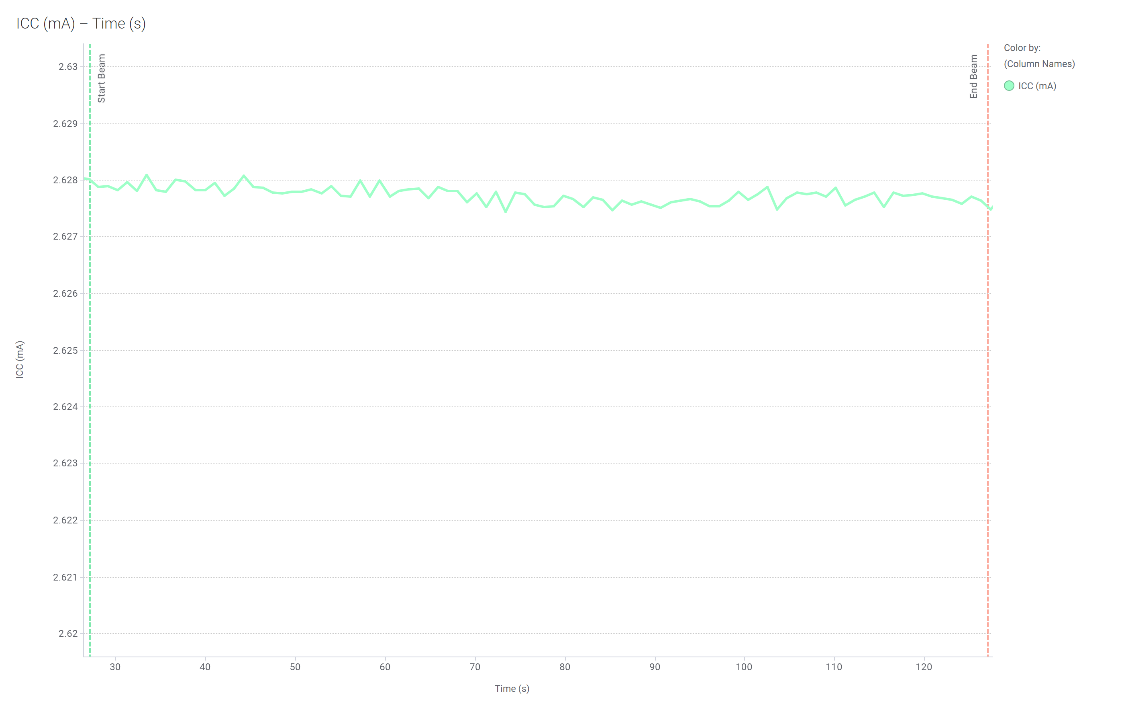

Current versus Time for Run

Number 4 of the SN54SC245-SEP at T = 125°C

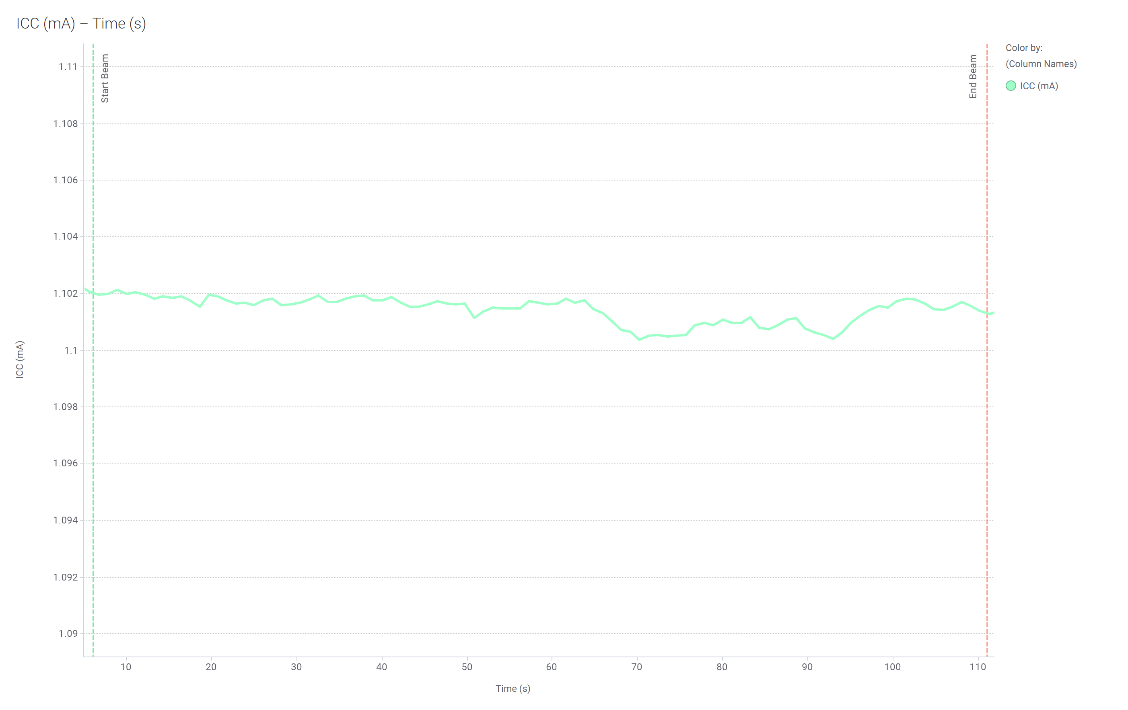

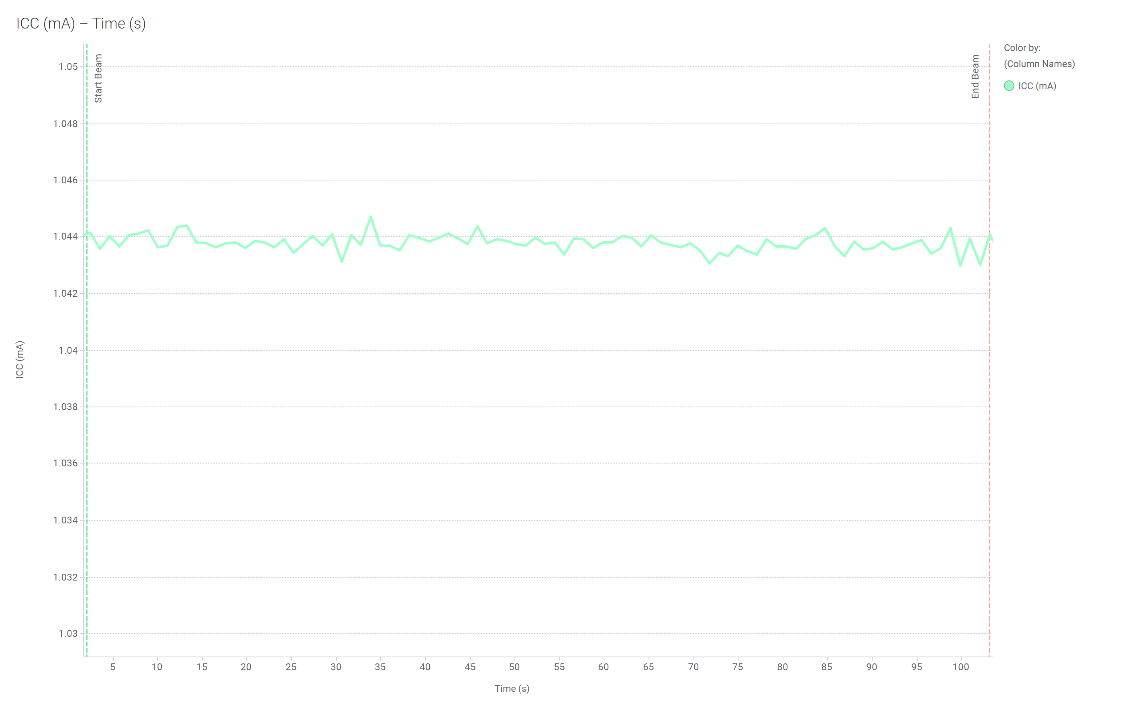

Current versus Time for Run

Number 7 of the SN54SC245-SEP at T = 125°C

No SEL events were observed, which indicates that

the SN54SC245-SEP is SEL-immune at LETEFF = 43 MeV-cm2 / mg

and T = 125°C. Using the MFTF method described in , the upper-bound

cross-section (using a 95% confidence level) is calculated as:

σSEL ≤ 1.23 × 10–7

cm2/ device for LETEFF = 43 MeV-cm2 / mg and T

= 125°C.

Event Rate Calculations

Event rates were calculated for LEO

(ISS) and GEO environments by combining CREME96 orbital integral flux estimations and

simplified SEE cross-sections according to methods described in

Heavy Ion Orbital

Environment Single-Event Effects Estimations

. A minimum shielding

configuration of 100 mils (2.54 mm) of aluminum and worst-week solar activity is

assumed. (This is similar to a 99% upper bound for the environment). #GUID-6B4B416D-3628-4DC4-A94C-86085585677E/SLAK0081309 lists the event rate calculations using the 95% upper-bounds for the SEL. It is

important to note that this number is for reference since no SEL events were

observed.

SEL Event Rate Calculations

for Worst-Week LEO and GEO Orbits

Orbit Type

Onset LET (MeV–cm2 / mg)

CREME96 Integral Flux ( / day–cm2)

σSAT (cm2)

Event Rate ( / day)

Event Rate (FIT)

MTBE (years)

LEO(ISS)

43

6.40 × 10-4

1.23 × 10-7

7.87 × 10-11

3.28 × 10-3

3.48 × 107

GEO

2.17 × 10-3

2.67 × 10-10

1.11 × 10-2

1.03 × 107

MTBE is the

mean-time-between-events in years at the given event rates. These rates clearly

demonstrate the SEE robustness of the SN54SC245-SEP in two harshly conservative

space environments. Customers using the SN54SC245-SEP must only use the above

estimations as a rough guide and TI recommends performing event rate calculations

based on specific mission orbital and shielding parameters to determine if the

product satisfies the reliability requirements for the specific

mission.

Results

SEL Results

During SEL characterization, the device was heated

using forced hot air, maintaining device temperature at 125°C. A FLIR (FLIR ONE Pro

LT) thermal camera was used to validate die temperature to make sure the device was

being accurately heated (see Figure 3-5). The species used for SEL testing was a

Xenon (129Xe) ion at a linac energy of 25 MeV / µ with an

angle-of-incidence of 0° for an LETEFF of 43 MeV-cm2 / mg. A

fluence of approximately 1 × 107 ions / cm2 were used for the

runs.

The three devices were powered up and exposed to

the heavy-ions using the maximum recommended supply voltage of 5.5 V with a National

Instruments PXI Chassis PXIe-1085 and a 5-V, 1 MHz square wave input using a

Tektronix AFG3102 function generator. The run duration to achieve this fluence was

approximately two minutes. As listed in , no SEL events were observed during the nine runs, which indicates that the

SN54SC245-SEP is SEL-free. , , and show the plot of current versus time for runs one, four, and seven,

respectively.

Summary of SN54SC245-SEP Test Conditions and Results

Run Number

Unit Number

Distance (mm)

Temperature (°C)

Ion

Angle

FLUX (ions × cm2 / mg)

Fluence (Number of ions)

LETEFF

(MeV × cm2 / mg)

Did an SEL event occur?

1

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

2

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

3

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

4

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

5

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

6

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

7

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

8

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

9

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

Current versus Time for Run

Number 1 of the SN54SC245-SEP at T = 125°C

Current versus Time for Run

Number 4 of the SN54SC245-SEP at T = 125°C

Current versus Time for Run

Number 7 of the SN54SC245-SEP at T = 125°C

No SEL events were observed, which indicates that

the SN54SC245-SEP is SEL-immune at LETEFF = 43 MeV-cm2 / mg

and T = 125°C. Using the MFTF method described in , the upper-bound

cross-section (using a 95% confidence level) is calculated as:

σSEL ≤ 1.23 × 10–7

cm2/ device for LETEFF = 43 MeV-cm2 / mg and T

= 125°C.

SEL Results

During SEL characterization, the device was heated

using forced hot air, maintaining device temperature at 125°C. A FLIR (FLIR ONE Pro

LT) thermal camera was used to validate die temperature to make sure the device was

being accurately heated (see Figure 3-5). The species used for SEL testing was a

Xenon (129Xe) ion at a linac energy of 25 MeV / µ with an

angle-of-incidence of 0° for an LETEFF of 43 MeV-cm2 / mg. A

fluence of approximately 1 × 107 ions / cm2 were used for the

runs.

The three devices were powered up and exposed to

the heavy-ions using the maximum recommended supply voltage of 5.5 V with a National

Instruments PXI Chassis PXIe-1085 and a 5-V, 1 MHz square wave input using a

Tektronix AFG3102 function generator. The run duration to achieve this fluence was

approximately two minutes. As listed in , no SEL events were observed during the nine runs, which indicates that the

SN54SC245-SEP is SEL-free. , , and show the plot of current versus time for runs one, four, and seven,

respectively.

Summary of SN54SC245-SEP Test Conditions and Results

Run Number

Unit Number

Distance (mm)

Temperature (°C)

Ion

Angle

FLUX (ions × cm2 / mg)

Fluence (Number of ions)

LETEFF

(MeV × cm2 / mg)

Did an SEL event occur?

1

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

2

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

3

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

4

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

5

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

6

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

7

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

8

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

9

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

Current versus Time for Run

Number 1 of the SN54SC245-SEP at T = 125°C

Current versus Time for Run

Number 4 of the SN54SC245-SEP at T = 125°C

Current versus Time for Run

Number 7 of the SN54SC245-SEP at T = 125°C

No SEL events were observed, which indicates that

the SN54SC245-SEP is SEL-immune at LETEFF = 43 MeV-cm2 / mg

and T = 125°C. Using the MFTF method described in , the upper-bound

cross-section (using a 95% confidence level) is calculated as:

σSEL ≤ 1.23 × 10–7

cm2/ device for LETEFF = 43 MeV-cm2 / mg and T

= 125°C.

During SEL characterization, the device was heated

using forced hot air, maintaining device temperature at 125°C. A FLIR (FLIR ONE Pro

LT) thermal camera was used to validate die temperature to make sure the device was

being accurately heated (see Figure 3-5). The species used for SEL testing was a

Xenon (129Xe) ion at a linac energy of 25 MeV / µ with an

angle-of-incidence of 0° for an LETEFF of 43 MeV-cm2 / mg. A

fluence of approximately 1 × 107 ions / cm2 were used for the

runs.

The three devices were powered up and exposed to

the heavy-ions using the maximum recommended supply voltage of 5.5 V with a National

Instruments PXI Chassis PXIe-1085 and a 5-V, 1 MHz square wave input using a

Tektronix AFG3102 function generator. The run duration to achieve this fluence was

approximately two minutes. As listed in , no SEL events were observed during the nine runs, which indicates that the

SN54SC245-SEP is SEL-free. , , and show the plot of current versus time for runs one, four, and seven,

respectively.

Summary of SN54SC245-SEP Test Conditions and Results

Run Number

Unit Number

Distance (mm)

Temperature (°C)

Ion

Angle

FLUX (ions × cm2 / mg)

Fluence (Number of ions)

LETEFF

(MeV × cm2 / mg)

Did an SEL event occur?

1

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

2

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

3

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

4

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

5

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

6

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

7

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

8

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

9

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

Current versus Time for Run

Number 1 of the SN54SC245-SEP at T = 125°C

Current versus Time for Run

Number 4 of the SN54SC245-SEP at T = 125°C

Current versus Time for Run

Number 7 of the SN54SC245-SEP at T = 125°C

No SEL events were observed, which indicates that

the SN54SC245-SEP is SEL-immune at LETEFF = 43 MeV-cm2 / mg

and T = 125°C. Using the MFTF method described in , the upper-bound

cross-section (using a 95% confidence level) is calculated as:

σSEL ≤ 1.23 × 10–7

cm2/ device for LETEFF = 43 MeV-cm2 / mg and T

= 125°C.

During SEL characterization, the device was heated

using forced hot air, maintaining device temperature at 125°C. A FLIR (FLIR ONE Pro

LT) thermal camera was used to validate die temperature to make sure the device was

being accurately heated (see Figure 3-5). The species used for SEL testing was a

Xenon (129Xe) ion at a linac energy of 25 MeV / µ with an

angle-of-incidence of 0° for an LETEFF of 43 MeV-cm2 / mg. A

fluence of approximately 1 × 107 ions / cm2 were used for the

runs.129EFF272The three devices were powered up and exposed to

the heavy-ions using the maximum recommended supply voltage of 5.5 V with a National

Instruments PXI Chassis PXIe-1085 and a 5-V, 1 MHz square wave input using a

Tektronix AFG3102 function generator. The run duration to achieve this fluence was

approximately two minutes. As listed in , no SEL events were observed during the nine runs, which indicates that the

SN54SC245-SEP is SEL-free. , , and show the plot of current versus time for runs one, four, and seven,

respectively.

Summary of SN54SC245-SEP Test Conditions and Results

Run Number

Unit Number

Distance (mm)

Temperature (°C)

Ion

Angle

FLUX (ions × cm2 / mg)

Fluence (Number of ions)

LETEFF

(MeV × cm2 / mg)

Did an SEL event occur?

1

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

2

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

3

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

4

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

5

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

6

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

7

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

8

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

9

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

Summary of SN54SC245-SEP Test Conditions and Results

Run Number

Unit Number

Distance (mm)

Temperature (°C)

Ion

Angle

FLUX (ions × cm2 / mg)

Fluence (Number of ions)

LETEFF

(MeV × cm2 / mg)

Did an SEL event occur?

1

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

2

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

3

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

4

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

5

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

6

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

7

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

8

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

9

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

Run Number

Unit Number

Distance (mm)

Temperature (°C)

Ion

Angle

FLUX (ions × cm2 / mg)

Fluence (Number of ions)

LETEFF

(MeV × cm2 / mg)

Did an SEL event occur?

Run Number

Unit Number

Distance (mm)

Temperature (°C)

Ion

Angle

FLUX (ions × cm2 / mg)

Fluence (Number of ions)

LETEFF

(MeV × cm2 / mg)

Did an SEL event occur?

Run NumberUnit NumberDistance (mm)Temperature (°C)IonAngleFLUX (ions × cm2 / mg)2Fluence (Number of ions)LETEFF

(MeV × cm2 / mg)EFF2Did an SEL event occur?

1

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

2

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

3

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

4

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

5

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

6

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

7

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

8

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

9

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

1

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

1170121Xe0°1.00E + 051.00E + 0743No

2

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

2170121Xe0°1.00E + 051.00E + 0743No

3

1

70

121

Xe

0°

1.00E + 05

1.00E + 07

43

No

3170121Xe0°1.00E + 051.00E + 0743No

4

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

4270124Xe0°1.00E + 051.00E + 0743No

5

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

5270124Xe0°1.00E + 051.00E + 0743No

6

2

70

124

Xe

0°

1.00E + 05

1.00E + 07

43

No

6270124Xe0°1.00E + 051.00E + 0743No

7

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

7370126Xe0°1.00E + 051.00E + 0743No

8

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

8370126Xe0°1.00E + 051.00E + 0743No

9

3

70

126

Xe

0°

1.00E + 05

1.00E + 07

43

No

9370126Xe0°1.00E + 051.00E + 0743No

Current versus Time for Run

Number 1 of the SN54SC245-SEP at T = 125°C

Current versus Time for Run

Number 1 of the SN54SC245-SEP at T = 125°C

Current versus Time for Run

Number 4 of the SN54SC245-SEP at T = 125°C

Current versus Time for Run

Number 4 of the SN54SC245-SEP at T = 125°C

Current versus Time for Run

Number 7 of the SN54SC245-SEP at T = 125°C

Current versus Time for Run

Number 7 of the SN54SC245-SEP at T = 125°CNo SEL events were observed, which indicates that

the SN54SC245-SEP is SEL-immune at LETEFF = 43 MeV-cm2 / mg

and T = 125°C. Using the MFTF method described in , the upper-bound

cross-section (using a 95% confidence level) is calculated as:EFF2σSEL ≤ 1.23 × 10–7

cm2/ device for LETEFF = 43 MeV-cm2 / mg and T

= 125°C.SEL–72EFF2

Event Rate Calculations

Event rates were calculated for LEO

(ISS) and GEO environments by combining CREME96 orbital integral flux estimations and

simplified SEE cross-sections according to methods described in

Heavy Ion Orbital

Environment Single-Event Effects Estimations

. A minimum shielding

configuration of 100 mils (2.54 mm) of aluminum and worst-week solar activity is

assumed. (This is similar to a 99% upper bound for the environment). #GUID-6B4B416D-3628-4DC4-A94C-86085585677E/SLAK0081309 lists the event rate calculations using the 95% upper-bounds for the SEL. It is

important to note that this number is for reference since no SEL events were

observed.

SEL Event Rate Calculations

for Worst-Week LEO and GEO Orbits

Orbit Type

Onset LET (MeV–cm2 / mg)

CREME96 Integral Flux ( / day–cm2)

σSAT (cm2)

Event Rate ( / day)

Event Rate (FIT)

MTBE (years)

LEO(ISS)

43

6.40 × 10-4

1.23 × 10-7

7.87 × 10-11

3.28 × 10-3

3.48 × 107

GEO

2.17 × 10-3

2.67 × 10-10

1.11 × 10-2

1.03 × 107

MTBE is the

mean-time-between-events in years at the given event rates. These rates clearly

demonstrate the SEE robustness of the SN54SC245-SEP in two harshly conservative

space environments. Customers using the SN54SC245-SEP must only use the above

estimations as a rough guide and TI recommends performing event rate calculations

based on specific mission orbital and shielding parameters to determine if the

product satisfies the reliability requirements for the specific

mission.

Event Rate Calculations

Event rates were calculated for LEO

(ISS) and GEO environments by combining CREME96 orbital integral flux estimations and

simplified SEE cross-sections according to methods described in

Heavy Ion Orbital

Environment Single-Event Effects Estimations

. A minimum shielding

configuration of 100 mils (2.54 mm) of aluminum and worst-week solar activity is

assumed. (This is similar to a 99% upper bound for the environment). #GUID-6B4B416D-3628-4DC4-A94C-86085585677E/SLAK0081309 lists the event rate calculations using the 95% upper-bounds for the SEL. It is

important to note that this number is for reference since no SEL events were

observed.

SEL Event Rate Calculations

for Worst-Week LEO and GEO Orbits

Orbit Type

Onset LET (MeV–cm2 / mg)

CREME96 Integral Flux ( / day–cm2)

σSAT (cm2)

Event Rate ( / day)

Event Rate (FIT)

MTBE (years)

LEO(ISS)

43

6.40 × 10-4

1.23 × 10-7

7.87 × 10-11

3.28 × 10-3

3.48 × 107

GEO

2.17 × 10-3

2.67 × 10-10

1.11 × 10-2

1.03 × 107

MTBE is the

mean-time-between-events in years at the given event rates. These rates clearly

demonstrate the SEE robustness of the SN54SC245-SEP in two harshly conservative

space environments. Customers using the SN54SC245-SEP must only use the above

estimations as a rough guide and TI recommends performing event rate calculations

based on specific mission orbital and shielding parameters to determine if the

product satisfies the reliability requirements for the specific

mission.

Event rates were calculated for LEO

(ISS) and GEO environments by combining CREME96 orbital integral flux estimations and

simplified SEE cross-sections according to methods described in

Heavy Ion Orbital

Environment Single-Event Effects Estimations

. A minimum shielding

configuration of 100 mils (2.54 mm) of aluminum and worst-week solar activity is

assumed. (This is similar to a 99% upper bound for the environment). #GUID-6B4B416D-3628-4DC4-A94C-86085585677E/SLAK0081309 lists the event rate calculations using the 95% upper-bounds for the SEL. It is

important to note that this number is for reference since no SEL events were

observed.

SEL Event Rate Calculations

for Worst-Week LEO and GEO Orbits

Orbit Type

Onset LET (MeV–cm2 / mg)

CREME96 Integral Flux ( / day–cm2)

σSAT (cm2)

Event Rate ( / day)

Event Rate (FIT)

MTBE (years)

LEO(ISS)

43

6.40 × 10-4

1.23 × 10-7

7.87 × 10-11

3.28 × 10-3

3.48 × 107

GEO

2.17 × 10-3

2.67 × 10-10

1.11 × 10-2

1.03 × 107

MTBE is the

mean-time-between-events in years at the given event rates. These rates clearly

demonstrate the SEE robustness of the SN54SC245-SEP in two harshly conservative

space environments. Customers using the SN54SC245-SEP must only use the above

estimations as a rough guide and TI recommends performing event rate calculations

based on specific mission orbital and shielding parameters to determine if the

product satisfies the reliability requirements for the specific

mission.

Heavy Ion Orbital

Environment Single-Event Effects Estimations

Heavy Ion Orbital

Environment Single-Event Effects Estimations#GUID-6B4B416D-3628-4DC4-A94C-86085585677E/SLAK0081309

SEL Event Rate Calculations

for Worst-Week LEO and GEO Orbits

Orbit Type

Onset LET (MeV–cm2 / mg)

CREME96 Integral Flux ( / day–cm2)

σSAT (cm2)

Event Rate ( / day)

Event Rate (FIT)

MTBE (years)

LEO(ISS)

43

6.40 × 10-4

1.23 × 10-7

7.87 × 10-11

3.28 × 10-3

3.48 × 107

GEO

2.17 × 10-3

2.67 × 10-10

1.11 × 10-2

1.03 × 107

SEL Event Rate Calculations

for Worst-Week LEO and GEO Orbits

Orbit Type

Onset LET (MeV–cm2 / mg)

CREME96 Integral Flux ( / day–cm2)

σSAT (cm2)

Event Rate ( / day)

Event Rate (FIT)

MTBE (years)

LEO(ISS)

43

6.40 × 10-4

1.23 × 10-7

7.87 × 10-11

3.28 × 10-3

3.48 × 107

GEO

2.17 × 10-3

2.67 × 10-10

1.11 × 10-2

1.03 × 107

Orbit Type

Onset LET (MeV–cm2 / mg)

CREME96 Integral Flux ( / day–cm2)

σSAT (cm2)

Event Rate ( / day)

Event Rate (FIT)

MTBE (years)

Orbit Type

Onset LET (MeV–cm2 / mg)

CREME96 Integral Flux ( / day–cm2)

σSAT (cm2)

Event Rate ( / day)

Event Rate (FIT)

MTBE (years)

Orbit TypeOnset LET (MeV–cm2 / mg)2CREME96 Integral Flux ( / day–cm2)2σSAT (cm2)SAT2Event Rate ( / day)Event Rate (FIT)MTBE (years)

LEO(ISS)

43

6.40 × 10-4

1.23 × 10-7

7.87 × 10-11

3.28 × 10-3

3.48 × 107

GEO

2.17 × 10-3

2.67 × 10-10

1.11 × 10-2

1.03 × 107

LEO(ISS)

43

6.40 × 10-4

1.23 × 10-7

7.87 × 10-11

3.28 × 10-3

3.48 × 107

LEO(ISS)436.40 × 10-4

-41.23 × 10-7

-77.87 × 10-11

-113.28 × 10-3

-33.48 × 107

7

GEO

2.17 × 10-3

2.67 × 10-10

1.11 × 10-2

1.03 × 107

GEO2.17 × 10-3

-32.67 × 10-10

-101.11 × 10-2

-21.03 × 107

7MTBE is the

mean-time-between-events in years at the given event rates. These rates clearly

demonstrate the SEE robustness of the SN54SC245-SEP in two harshly conservative

space environments. Customers using the SN54SC245-SEP must only use the above

estimations as a rough guide and TI recommends performing event rate calculations

based on specific mission orbital and shielding parameters to determine if the

product satisfies the reliability requirements for the specific

mission.

Summary

The purpose of this study was to characterize the

effects of heavy-ion irradiation on the single-event latch-up (SEL) performance of

the SN54SC245-SEP, a radiation-tolerant 1.2-V to 5.5-V octal bus transceivers with

tri-state outputs. Heavy-ions with an LETEFF of 43 MeV-cm2 /

mg were used for the SEE characterization. The SEE results demonstrated that the

SN54SC245-SEP is SEL-free up to LETEFF = 43 MeV × cm2 / mg

and across the full electrical specifications. CREME96-based worst-week event-rate

calculations for LEO (ISS) and GEO orbits for the DSEE are shown for reference.

Summary

The purpose of this study was to characterize the

effects of heavy-ion irradiation on the single-event latch-up (SEL) performance of

the SN54SC245-SEP, a radiation-tolerant 1.2-V to 5.5-V octal bus transceivers with

tri-state outputs. Heavy-ions with an LETEFF of 43 MeV-cm2 /

mg were used for the SEE characterization. The SEE results demonstrated that the

SN54SC245-SEP is SEL-free up to LETEFF = 43 MeV × cm2 / mg

and across the full electrical specifications. CREME96-based worst-week event-rate

calculations for LEO (ISS) and GEO orbits for the DSEE are shown for reference.

The purpose of this study was to characterize the

effects of heavy-ion irradiation on the single-event latch-up (SEL) performance of

the SN54SC245-SEP, a radiation-tolerant 1.2-V to 5.5-V octal bus transceivers with

tri-state outputs. Heavy-ions with an LETEFF of 43 MeV-cm2 /

mg were used for the SEE characterization. The SEE results demonstrated that the

SN54SC245-SEP is SEL-free up to LETEFF = 43 MeV × cm2 / mg

and across the full electrical specifications. CREME96-based worst-week event-rate

calculations for LEO (ISS) and GEO orbits for the DSEE are shown for reference.

The purpose of this study was to characterize the

effects of heavy-ion irradiation on the single-event latch-up (SEL) performance of

the SN54SC245-SEP, a radiation-tolerant 1.2-V to 5.5-V octal bus transceivers with

tri-state outputs. Heavy-ions with an LETEFF of 43 MeV-cm2 /

mg were used for the SEE characterization. The SEE results demonstrated that the

SN54SC245-SEP is SEL-free up to LETEFF = 43 MeV × cm2 / mg

and across the full electrical specifications. CREME96-based worst-week event-rate

calculations for LEO (ISS) and GEO orbits for the DSEE are shown for reference.EFF2EFF2

References

M. Shoga and D. Binder, "Theory of

Single Event Latchup in Complementary Metal-Oxide Semiconductor Integrated

Circuits", IEEE Trans. Nucl. Sci., Vol. 33(6), Dec. 1986, pp.

1714-1717.

G. Bruguier and J. M. Palau,

"Single particle-induced latchup", IEEE Trans. Nucl. Sci., Vol. 43(2),

Mar. 1996, pp. 522-532.

Cyclotron Institute, Texas A&M

University,

Texas A&M University Cyclotron Institute Radiation

Effects Facility

, webpage.

James F. Ziegler,

"The Stopping and Range of Ions in Matter" software simulation

tool, webpage.

D. Kececioglu, “Reliability and

Life Testing Handbook”, Vol. 1, PTR Prentice Hall, New Jersey,1993, pp.

186-193.

Vanderbilt University,

ISDE CRÈME-MC

, webpage.

A. J. Tylka, J. H. Adams, P. R.

Boberg, et al.,"CREME96: A Revision of the Cosmic Ray Effects on

Micro-Electronics Code", IEEE Trans. on Nucl. Sci., Vol. 44(6), Dec.

1997, pp. 2150-2160.

A. J. Tylka, W. F. Dietrich, and P.

R. Boberg, "Probability distributions of high-energy solar-heavy-ion fluxes from

IMP-8: 1973-1996", IEEE Trans. on Nucl. Sci.,Vol. 44(6), Dec. 1997, pp.

2140-2149.

References

M. Shoga and D. Binder, "Theory of

Single Event Latchup in Complementary Metal-Oxide Semiconductor Integrated

Circuits", IEEE Trans. Nucl. Sci., Vol. 33(6), Dec. 1986, pp.

1714-1717.

G. Bruguier and J. M. Palau,

"Single particle-induced latchup", IEEE Trans. Nucl. Sci., Vol. 43(2),

Mar. 1996, pp. 522-532.

Cyclotron Institute, Texas A&M

University,

Texas A&M University Cyclotron Institute Radiation

Effects Facility

, webpage.

James F. Ziegler,

"The Stopping and Range of Ions in Matter" software simulation

tool, webpage.

D. Kececioglu, “Reliability and

Life Testing Handbook”, Vol. 1, PTR Prentice Hall, New Jersey,1993, pp.

186-193.

Vanderbilt University,

ISDE CRÈME-MC

, webpage.

A. J. Tylka, J. H. Adams, P. R.

Boberg, et al.,"CREME96: A Revision of the Cosmic Ray Effects on

Micro-Electronics Code", IEEE Trans. on Nucl. Sci., Vol. 44(6), Dec.

1997, pp. 2150-2160.

A. J. Tylka, W. F. Dietrich, and P.

R. Boberg, "Probability distributions of high-energy solar-heavy-ion fluxes from

IMP-8: 1973-1996", IEEE Trans. on Nucl. Sci.,Vol. 44(6), Dec. 1997, pp.

2140-2149.

M. Shoga and D. Binder, "Theory of

Single Event Latchup in Complementary Metal-Oxide Semiconductor Integrated

Circuits", IEEE Trans. Nucl. Sci., Vol. 33(6), Dec. 1986, pp.

1714-1717.

G. Bruguier and J. M. Palau,

"Single particle-induced latchup", IEEE Trans. Nucl. Sci., Vol. 43(2),

Mar. 1996, pp. 522-532.

Cyclotron Institute, Texas A&M

University,

Texas A&M University Cyclotron Institute Radiation

Effects Facility

, webpage.

James F. Ziegler,

"The Stopping and Range of Ions in Matter" software simulation

tool, webpage.

D. Kececioglu, “Reliability and

Life Testing Handbook”, Vol. 1, PTR Prentice Hall, New Jersey,1993, pp.

186-193.

Vanderbilt University,

ISDE CRÈME-MC

, webpage.

A. J. Tylka, J. H. Adams, P. R.

Boberg, et al.,"CREME96: A Revision of the Cosmic Ray Effects on

Micro-Electronics Code", IEEE Trans. on Nucl. Sci., Vol. 44(6), Dec.

1997, pp. 2150-2160.

A. J. Tylka, W. F. Dietrich, and P.

R. Boberg, "Probability distributions of high-energy solar-heavy-ion fluxes from

IMP-8: 1973-1996", IEEE Trans. on Nucl. Sci.,Vol. 44(6), Dec. 1997, pp.

2140-2149.

M. Shoga and D. Binder, "Theory of

Single Event Latchup in Complementary Metal-Oxide Semiconductor Integrated

Circuits", IEEE Trans. Nucl. Sci., Vol. 33(6), Dec. 1986, pp.

1714-1717.

G. Bruguier and J. M. Palau,

"Single particle-induced latchup", IEEE Trans. Nucl. Sci., Vol. 43(2),

Mar. 1996, pp. 522-532.

Cyclotron Institute, Texas A&M

University,

Texas A&M University Cyclotron Institute Radiation

Effects Facility

, webpage.

James F. Ziegler,

"The Stopping and Range of Ions in Matter" software simulation

tool, webpage.

D. Kececioglu, “Reliability and

Life Testing Handbook”, Vol. 1, PTR Prentice Hall, New Jersey,1993, pp.

186-193.

Vanderbilt University,

ISDE CRÈME-MC

, webpage.

A. J. Tylka, J. H. Adams, P. R.

Boberg, et al.,"CREME96: A Revision of the Cosmic Ray Effects on

Micro-Electronics Code", IEEE Trans. on Nucl. Sci., Vol. 44(6), Dec.

1997, pp. 2150-2160.

A. J. Tylka, W. F. Dietrich, and P.

R. Boberg, "Probability distributions of high-energy solar-heavy-ion fluxes from

IMP-8: 1973-1996", IEEE Trans. on Nucl. Sci.,Vol. 44(6), Dec. 1997, pp.

2140-2149.

M. Shoga and D. Binder, "Theory of

Single Event Latchup in Complementary Metal-Oxide Semiconductor Integrated

Circuits", IEEE Trans. Nucl. Sci., Vol. 33(6), Dec. 1986, pp.

1714-1717.IEEE Trans. Nucl. Sci., Vol. 33(6)G. Bruguier and J. M. Palau,

"Single particle-induced latchup", IEEE Trans. Nucl. Sci., Vol. 43(2),

Mar. 1996, pp. 522-532.IEEE Trans. Nucl. Sci., Vol. 43(2)Cyclotron Institute, Texas A&M

University,

Texas A&M University Cyclotron Institute Radiation

Effects Facility

, webpage.

Texas A&M University Cyclotron Institute Radiation

Effects Facility

Texas A&M University Cyclotron Institute Radiation

Effects Facility James F. Ziegler,

"The Stopping and Range of Ions in Matter" software simulation

tool, webpage.

"The Stopping and Range of Ions in Matter" software simulation

tool"The Stopping and Range of Ions in Matter"D. Kececioglu, “Reliability and

Life Testing Handbook”, Vol. 1, PTR Prentice Hall, New Jersey,1993, pp.

186-193.Vanderbilt University,

ISDE CRÈME-MC

, webpage.

ISDE CRÈME-MC

ISDE CRÈME-MC A. J. Tylka, J. H. Adams, P. R.

Boberg, et al.,"CREME96: A Revision of the Cosmic Ray Effects on

Micro-Electronics Code", IEEE Trans. on Nucl. Sci., Vol. 44(6), Dec.

1997, pp. 2150-2160.IEEE Trans. on Nucl. Sci., Vol. 44(6)A. J. Tylka, W. F. Dietrich, and P.

R. Boberg, "Probability distributions of high-energy solar-heavy-ion fluxes from

IMP-8: 1973-1996", IEEE Trans. on Nucl. Sci.,Vol. 44(6), Dec. 1997, pp.

2140-2149.IEEE Trans. on Nucl. Sci.,Vol. 44(6)

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING

DATA SHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION

OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER

RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES,

EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES

OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT

OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers

designing with TI products. You are solely responsible for (1) selecting

the appropriate TI products for your application, (2) designing,

validating and testing your application, and (3) ensuring your

application meets applicable standards, and any other safety, security, regulatory

or other requirements.

These resources are subject to change without

notice. TI grants you permission to use these resources only for

development of an application that uses the TI products described in the

resource. Other reproduction and display of these resources is

prohibited. No license is granted to any other TI intellectual property

right or to any third party intellectual property right. TI disclaims

responsibility for, and you will fully indemnify TI and its

representatives against, any claims, damages, costs, losses, and

liabilities arising out of your use of these resources.

TI’s products are provided subject to

TI’s Terms of Sale or other applicable

terms available either on ti.com or provided in conjunction with such

TI products. TI’s provision of these resources does not expand or

otherwise alter TI’s applicable warranties or warranty disclaimers for

TI products.

TI objects to and rejects any additional or different terms you may have proposed. IMPORTANT NOTICE

Mailing Address:

Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING

DATA SHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION

OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER

RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES,

EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES

OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT

OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers

designing with TI products. You are solely responsible for (1) selecting

the appropriate TI products for your application, (2) designing,

validating and testing your application, and (3) ensuring your

application meets applicable standards, and any other safety, security, regulatory

or other requirements.

These resources are subject to change without

notice. TI grants you permission to use these resources only for

development of an application that uses the TI products described in the

resource. Other reproduction and display of these resources is

prohibited. No license is granted to any other TI intellectual property

right or to any third party intellectual property right. TI disclaims

responsibility for, and you will fully indemnify TI and its

representatives against, any claims, damages, costs, losses, and

liabilities arising out of your use of these resources.

TI’s products are provided subject to

TI’s Terms of Sale or other applicable

terms available either on ti.com or provided in conjunction with such

TI products. TI’s provision of these resources does not expand or

otherwise alter TI’s applicable warranties or warranty disclaimers for

TI products.

TI objects to and rejects any additional or different terms you may have proposed. IMPORTANT NOTICE

Mailing Address:

Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING

DATA SHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION

OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER

RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES,

EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES

OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT

OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers

designing with TI products. You are solely responsible for (1) selecting

the appropriate TI products for your application, (2) designing,

validating and testing your application, and (3) ensuring your

application meets applicable standards, and any other safety, security, regulatory

or other requirements.

These resources are subject to change without

notice. TI grants you permission to use these resources only for

development of an application that uses the TI products described in the

resource. Other reproduction and display of these resources is

prohibited. No license is granted to any other TI intellectual property

right or to any third party intellectual property right. TI disclaims

responsibility for, and you will fully indemnify TI and its

representatives against, any claims, damages, costs, losses, and

liabilities arising out of your use of these resources.

TI’s products are provided subject to

TI’s Terms of Sale or other applicable

terms available either on ti.com or provided in conjunction with such

TI products. TI’s provision of these resources does not expand or

otherwise alter TI’s applicable warranties or warranty disclaimers for

TI products.

TI objects to and rejects any additional or different terms you may have proposed. IMPORTANT NOTICE

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING

DATA SHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION

OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER

RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES,

EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES

OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT

OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers

designing with TI products. You are solely responsible for (1) selecting

the appropriate TI products for your application, (2) designing,

validating and testing your application, and (3) ensuring your

application meets applicable standards, and any other safety, security, regulatory

or other requirements.

These resources are subject to change without

notice. TI grants you permission to use these resources only for

development of an application that uses the TI products described in the

resource. Other reproduction and display of these resources is

prohibited. No license is granted to any other TI intellectual property

right or to any third party intellectual property right. TI disclaims

responsibility for, and you will fully indemnify TI and its

representatives against, any claims, damages, costs, losses, and

liabilities arising out of your use of these resources.

TI’s products are provided subject to

TI’s Terms of Sale or other applicable

terms available either on ti.com or provided in conjunction with such

TI products. TI’s provision of these resources does not expand or

otherwise alter TI’s applicable warranties or warranty disclaimers for

TI products.

TI objects to and rejects any additional or different terms you may have proposed. IMPORTANT NOTICE

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING

DATA SHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION

OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER

RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES,

EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES

OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT

OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers

designing with TI products. You are solely responsible for (1) selecting

the appropriate TI products for your application, (2) designing,

validating and testing your application, and (3) ensuring your

application meets applicable standards, and any other safety, security, regulatory

or other requirements.

These resources are subject to change without

notice. TI grants you permission to use these resources only for

development of an application that uses the TI products described in the

resource. Other reproduction and display of these resources is

prohibited. No license is granted to any other TI intellectual property

right or to any third party intellectual property right. TI disclaims

responsibility for, and you will fully indemnify TI and its

representatives against, any claims, damages, costs, losses, and

liabilities arising out of your use of these resources.

TI’s products are provided subject to

TI’s Terms of Sale or other applicable

terms available either on ti.com or provided in conjunction with such

TI products. TI’s provision of these resources does not expand or

otherwise alter TI’s applicable warranties or warranty disclaimers for

TI products.

TI objects to and rejects any additional or different terms you may have proposed. IMPORTANT NOTICE

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING

DATA SHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION

OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER

RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES,

EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES

OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT

OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING

DATA SHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION

OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER

RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES,

EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES

OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT

OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers

designing with TI products. You are solely responsible for (1) selecting

the appropriate TI products for your application, (2) designing,

validating and testing your application, and (3) ensuring your

application meets applicable standards, and any other safety, security, regulatory

or other requirements.

These resources are intended for skilled developers

designing with TI products. You are solely responsible for (1) selecting

the appropriate TI products for your application, (2) designing,

validating and testing your application, and (3) ensuring your

application meets applicable standards, and any other safety, security, regulatory

or other requirements.

These resources are subject to change without

notice. TI grants you permission to use these resources only for

development of an application that uses the TI products described in the

resource. Other reproduction and display of these resources is

prohibited. No license is granted to any other TI intellectual property

right or to any third party intellectual property right. TI disclaims

responsibility for, and you will fully indemnify TI and its

representatives against, any claims, damages, costs, losses, and

liabilities arising out of your use of these resources.

These resources are subject to change without

notice. TI grants you permission to use these resources only for

development of an application that uses the TI products described in the

resource. Other reproduction and display of these resources is

prohibited. No license is granted to any other TI intellectual property

right or to any third party intellectual property right. TI disclaims

responsibility for, and you will fully indemnify TI and its

representatives against, any claims, damages, costs, losses, and

liabilities arising out of your use of these resources.

TI’s products are provided subject to

TI’s Terms of Sale or other applicable

terms available either on ti.com or provided in conjunction with such

TI products. TI’s provision of these resources does not expand or

otherwise alter TI’s applicable warranties or warranty disclaimers for

TI products.

TI’s products are provided subject to

TI’s Terms of Sale or other applicable

terms available either on ti.com or provided in conjunction with such

TI products. TI’s provision of these resources does not expand or

otherwise alter TI’s applicable warranties or warranty disclaimers for

TI products.TI’s Terms of Saleti.com

TI objects to and rejects any additional or different terms you may have proposed. IMPORTANT NOTICE

TI objects to and rejects any additional or different terms you may have proposed. IMPORTANT NOTICE

IMPORTANT NOTICE

Mailing Address:

Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated

Mailing Address:

Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated

Mailing Address:

Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated

Mailing Address:

Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated

Mailing Address:

Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2023, Texas Instruments Incorporated

Copyright © 2023, Texas Instruments Incorporated, the upper-bound

cross-section (using a 95% confidence level) is calculated as:

Equation 1. σSEL ≤ 1.23 × 10–7

cm2/ device for LETEFF = 43 MeV-cm2 / mg and T

= 125°C.

Figure 5-1 Current versus Time for Run

Number 1 of the SN54SC245-SEP at T = 125°C

Figure 5-1 Current versus Time for Run

Number 1 of the SN54SC245-SEP at T = 125°C Figure 5-2 Current versus Time for Run

Number 4 of the SN54SC245-SEP at T = 125°C

Figure 5-2 Current versus Time for Run

Number 4 of the SN54SC245-SEP at T = 125°C Figure 5-3 Current versus Time for Run

Number 7 of the SN54SC245-SEP at T = 125°C

Figure 5-3 Current versus Time for Run

Number 7 of the SN54SC245-SEP at T = 125°C