SLAU927A March 2024 – June 2024 MSPM0G3507

- 1

- Abstract

- Trademarks

- 1Introduction

-

2Hardware Setup

- 2.1 EVM Hardware Setup

- 2.2 Pin Configurations for IPD Usage

- 2.3 Pin Configurations for PWM Outputs

- 2.4 Pin Configurations for ADC Currents

- 2.5 Pin Configurations for ADC Voltages

- 2.6 Pin Configurations for Faults

- 2.7 Pin Configurations for GPIO Output Functions

- 2.8 Pin Configurations for SPI Communication

- 2.9 Pin Configurations for UART Communication

- 2.10 External Connections for Evaluation Boards

- 3Software Setup

- 4GUI Setup

- 5Register Map

- 6Basic Tuning

-

7Advanced Tuning

- 7.1

Control Configurations Tuning

- 7.1.1 Initial Speed Detection of the Motor for Reliable Motor Resynchronization

- 7.1.2 Unidirectional Motor Drive Detecting Backward Spin

- 7.1.3 Preventing Back Spin of Rotor During Startup

- 7.1.4 Gradual and Smooth Start up Motion

- 7.1.5 Faster Startup Timing

- 7.1.6 Stopping Motor Quickly

- 7.1.7 Flux Weakening : Operating Motor at Speeds Higher than Rated Speed

- 7.1.8 Maximum Torque Per Ampere : Improve Efficiency of IPMSM Motors

- 7.1.9 Preventing Supply Voltage Overshoot During Motor Stop.

- 7.1.10 Protecting the Power Supply

- 7.1.11 FOC Bandwidth Selection

- 7.1

Control Configurations Tuning

- 8Hardware Configurations

- 9Revision History

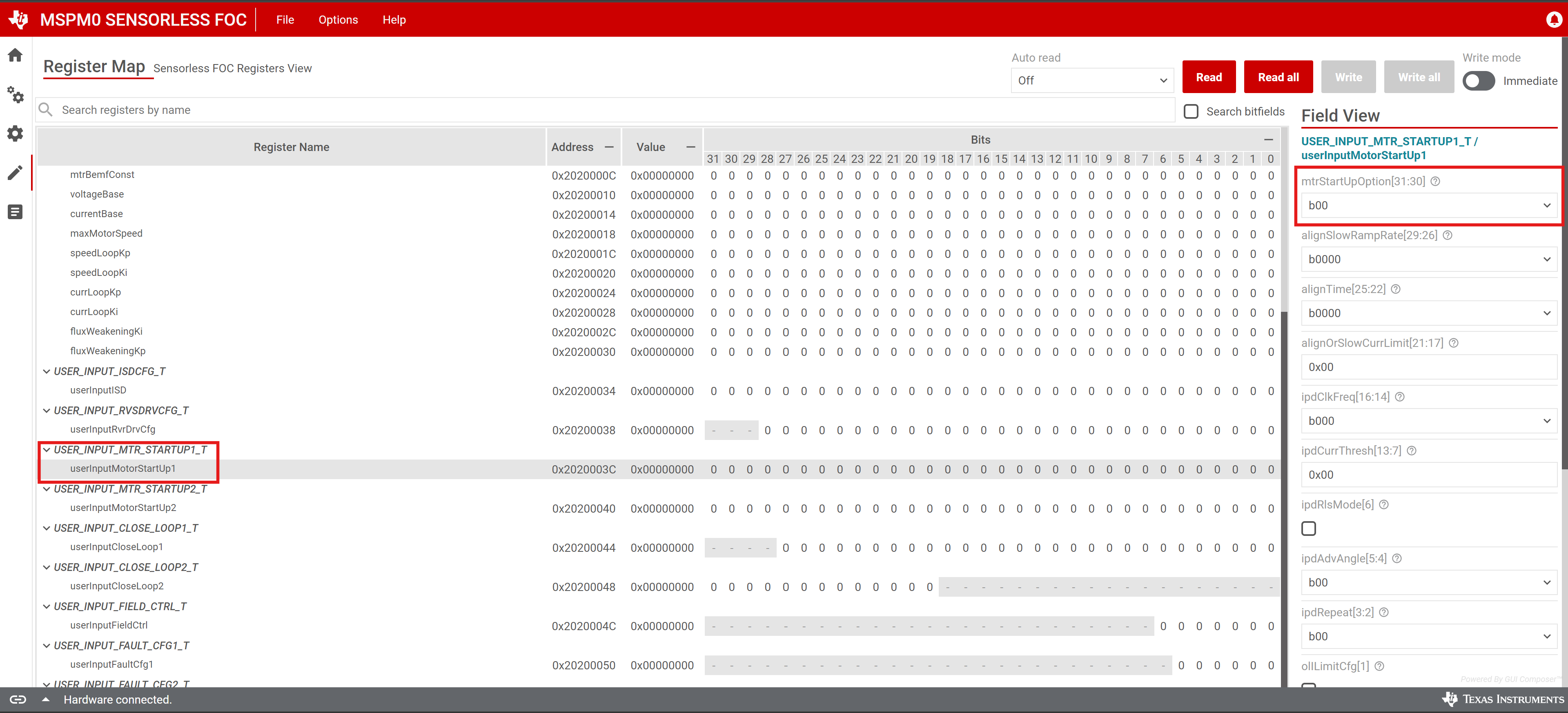

6.2.1.2 Motor Start Option - Align

When the motor is ramping up from standstill, the Motor Align startup algorithm forces the rotor to align to a fixed ALIGN_ANGLE with a defined current limit acting as a torque reference for a predefined ALIGN_TIME. By default, the motor startup option is set as Align (mtrStartUpOption = 0b) in the MTR_STARTUP of MOTOR_STARTUP1 configuration. For basic spinning, use the default parameters which works for most of the motors.

If the motor fails to align for the given load setup, increase the alignOrSlowCurrentLimit parameter on the Register Map page. For fine tuning the Motor Align configuration, refer to Section 7.

Figure 6-6 Motor Startup in GUI