SLAU948 October 2024 MSPM0G3507

- 1

- Abstract

- Trademarks

- 1Introduction

-

2Hardware Setup

- 2.1 EVM Hardware Setup

- 2.2 Pin Configurations for PWM Outputs

- 2.3 Pin Configurations for ADC Currents

- 2.4 Pin Configurations for ADC Voltages

- 2.5 Pin Configurations for Hall Sensor Inputs Through GPIO

- 2.6 Pin Configurations for Faults

- 2.7 Pin Configurations for GPIO Output Functions

- 2.8 Pin Configurations for SPI Communication

- 2.9 Pin Configurations for UART Communication

- 2.10 External Connections for Evaluation Boards

- 3Software Setup

- 4GUI Setup

-

5Register Map

- 5.1 Register Map Page in GUI

- 5.2

User Control Registers (Base Address = 0x20200400h)

- 5.2.1 Speed Control Register (Offset = 0h) [Reset = 00000000h]

- 5.2.2 Algo Debug Control 1 Register (Offset = 4h) [Reset = 00000000h]

- 5.2.3 Algo Debug Control 2 Register (Offset = 8h) [Reset = 00000000h]

- 5.2.4 Algo Debug Control 3 Register (Offset = Ch) [Reset = 00000000h]

- 5.2.5 DAC Configuration Register (Offset = 10h) [Reset = 00000000h]

- 5.3

User Input Registers (Base Address = 0x20200000h)

- 5.3.1 SYSTEM_PARAMETERS (Offset = 0h)

- 5.3.2 MOTOR_STARTUP1 Register (Offset = 3Ch) [Reset = 00000000h]

- 5.3.3 MOTOR_STARTUP2 Register (Offset = 40h) [Reset = 00000000h]

- 5.3.4 CLOSED_LOOP1 Register (Offset = 44h) [Reset = 00000000h]

- 5.3.5 CLOSED_LOOP2 Register (Offset = 48h) [Reset = 00000000h]

- 5.3.6 FIELD_CTRL Register (Offset = 4Ch) [Reset = 00000000h]

- 5.3.7 FAULT_CONFIG1 Register (Offset = 50h) [Reset = 00000000h]

- 5.3.8 FAULT_CONFIG2 Register (Offset = 54h) [Reset = 00000000h]

- 5.3.9 MISC_ALGO Register (Offset = 58h) [Reset = 00000000h]

- 5.3.10 PIN_CONFIG Register (Offset = 5Ch) [Reset = 00000000h]

- 5.3.11 PERI_CONFIG Register (Offset = 60h) [Reset = 00000000h]

- 5.4 User Status Registers (Base Address = 0x20200430h)

- 6Basic Tuning

-

7Advanced Tuning

- 7.1

Control Configurations Tuning

- 7.1.1 Control Mode of Operation

- 7.1.2 Closed Loop Torque Control Mode

- 7.1.3 Closed Loop Power Control Mode

- 7.1.4 Closed Loop Speed Control Mode

- 7.1.5 Voltage Control Mode

- 7.1.6 Stopping Motor Quickly

- 7.1.7 Flux Weakening: Operating Motor at Speeds Higher Than Rated Speed

- 7.1.8 Maximum Torque Per Ampere : Improve Efficiency of IPMSM Motors

- 7.1.9 Preventing Supply Voltage Overshoot During Motor Stop.

- 7.1.10 Protecting the Power Supply

- 7.1.11 FOC Bandwidth Selection

- 7.1

Control Configurations Tuning

- 8Hardware Configurations

2 Hardware Setup

The following items are required to use this tuning guide:

- LP-MSPM0G3507 board

- Supported DRV83xx motor driver

evaluation module (EVM)

- DRV8316REVM

- Jumper wires for pin table connections

- A computer with the MSPM0 Latest SDK software installed

- A BLDC motor with Hall Sensor to be tuned using this process. The motor data sheet is helpful but not mandatory.

- A DC power supply rated for the motor

- Basic lab equipment such as a digital multimeter (DMM), oscilloscope, current probe, and voltage probe

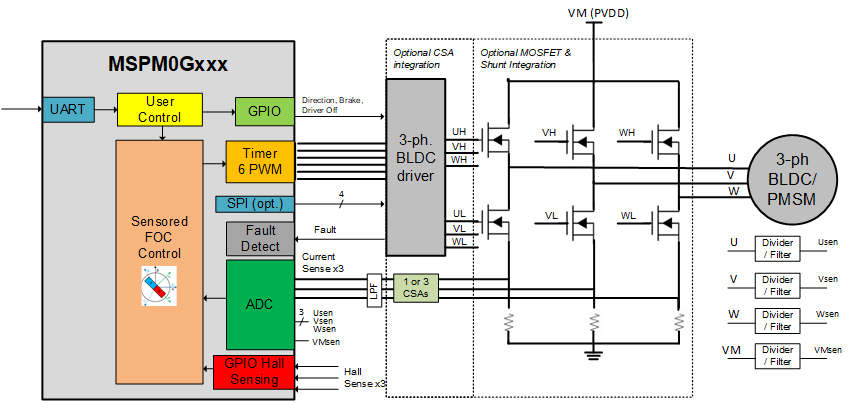

Figure 2-1 shows the block diagram connections for a Sensored FOC motor system. The system can be built using:

- TI-provided hardware (LP-MSPM0G3507 and DRV83xx EVM)

- Custom PCB hardware with an onboard MSPM0Gxxx MCU and a BLDC motor driver

The following sections describe how to configure the pins for each portion of the Sensored FOC block diagram.

Figure 2-1 MSPM0Gxxx + BLDC Motor Driver

- Sensored FOC Block Diagram

Figure 2-1 MSPM0Gxxx + BLDC Motor Driver

- Sensored FOC Block DiagramThe System Configuration tool (SysConfig) helps to configure the pins in a motor control system. The default pin configurations are provided for the EVM hardware setup to spin a motor, but pins can be remapped to other pins visually inside SysConfig. This is useful for reconfiguring different pins (such as PWM, ADC, or other control signals) on a custom PCB or for scaling to different packages across MSPM0 devices.