SLOA319 October 2021 TAS5828M , TPA3116D2

1 Application Brief

This application brief assists in the transition from an analog input audio amplifier to a digital input audio amplifier. The document addresses factors to consider before switching, the differences between two such devices, and how to make the switch. Texas Instruments’ (TI) TPA3116D2 (analog input) and TAS5828M (digital input) are used as examples.

Factors to Consider Before Switching

Before deciding to make the switch, it is necessary to understand the system and its requirements. Items to note are the possible audio inputs needed to interface with the audio amplifier, such as an output from the system on the chip (SoC) or connections to other audio connections, such as an audio jack.

Switching to a digital-input device could help save board space, increase efficiency, and provide additional features not found in its analog counterpart. For instance, the TAS5828M, a 50-W stereo high-performance closed-loop Class-D amplifier, eliminates the need for a digital-to-analog converter (DAC), supports digital signal processing (DSP) up to 192 kHz, and has Class-H modulation for efficiency improvements.

When discussing the system, an SoC with an internal DSP system may not need the capabilities inside the digital input device. However, if the goal is to reduce external components, extend battery life, the system is noise sensitive, or any combination of these, then a digital input device may be more suitable. Note that the TAS5828M requires the SoC to have I2C communication to use its software mode(1). The hardware mode(1) of the TAS5825M allows the device to be loaded in a default configuration which can be useful in cases where processing is handled upstream in the SoC. I2C is still required for more advanced processing features.

Other important requirements to consider include the compatibility of the heat sink and the desired electrical characteristics.

While the TPA3116D2 and TAS5828M are used as examples in this document, Texas Instruments offers the How to Choose a Class-D Audio Amplifier white paper to assist in device selection based on customer needs.

The Difference Between Analog and Digital Input Devices

At a high level, analog input devices are simpler and do not have integrated DSP. Digital input devices are typically integrated solutions that remove the need of an external DAC and can have signal processing or other additional software capabilities and features.

When comparing two of TI’s solutions, Table 1-1 summarizes the key features and differences between the TPA3116D2 and the TAS5828M. The paragraphs following Table 1-1 differentiate the two devices in terms of the full solution size, Class-H control capabilities, and the PWM modulation.

| Feature | TPA3116D2 | TAS5828M |

|---|---|---|

| Class-H Control | Not supported | Supports Class-H control (boost converter FB pin) |

| DSP Processing | Not supported | Supported |

| DSP Sample Rate | Not applicable | Up to 192 kHz |

| Low EMI Mode | Not supported | Spread Spectrum, PWM de-phase |

| PVDD Sense ADC | Not supported | Supported (prevents clipping and creates even PVDD drops) |

| PWM Modulation | BD, 1 SPW | BD, 1 SPW, Hybrid |

| SDOUT | Not supported | Supported |

| Thermal Management | Not supported | 4-level thermal warning with thermal foldback |

| Solution Size | 4 sub-sytems (requires external DAC) | 2 sub-systems (internal DAC) |

Solution Size

Typically, the TPA3116D2 has four sub-systems in its solution (see Figure 1-1 for details). The SoC signal must first be converted to an analog signal before it is used by the TPA3116D2 device. The conventional configuration for this solution requires additional external components: a quad-channel op-amp, 13 resistors, six capacitors, and a MOSFET.

Figure 1-1 Typical Analog Audio Amplifier Configuration

The TAS5828M reduces the amount of external hardware used (see Figure 1-2 for details). This device provides a two sub-system solution, removing the need of an external DAC and filtering because it is a part of the integrated solution. Additionally, this solution reduces the external components to three resistors and two capacitors.

Figure 1-2 Typical Digital Audio Amplifier Configuration

Class-H Control and Hybrid-Pro Algorithm

As previously discussed, the TAS5828M includes more features and increases overall efficiency. More importantly in battery-powered speakers, the TAS5828M can utilize the Class-H control and Hybrid-Pro algorithm to increase power efficiency. This increase in efficiency allows designers to increase the battery life of the existing cell, or use a smaller cell to maintain the same battery life while reducing cost.

The Class-H Control is one of the most powerful features of the TAS5828M device, which is not available in analog input devices. The Class-H control induces switching of the supply voltage to increase the overall efficiency and performance of the system. TI utilizes the Hybrid-Pro algorithm audio signal tracking and a maximum 4-ms delay buffer to avoid clipping of the audio signal.

Figure 1-3 shows the Hybrid-Pro algorithm detecting the upcoming audio peak and indicating the PVDD value to be adjusted. If the audio peak increases or decreases, the DC-DC converter adjusts the output power. As the audio signal changes, the Hybrid-Pro algorithm detects the audio peak and adjusts the output voltage accordingly. Refer to How to extend battery life and reduce power consumption with Class-D audio amplifiers for additional information on Class-H control and the Hybrid-Pro algorithm.

Figure 1-3 TAS5828M Hybrid-Pro Envelope Tracking

PWM Modulation

The internal PWM modulation capability inside both the TPA3116D2 and the TAS5828M improves sound clarity and reduces the signal-to-noise ratio (SNR). However, the TAS5828M PWM modulation has a lower idle current, lower SNR, and reduces the pop-and-click noise to under 30 dB compared to its analog counterpart.

Transitioning from Analog to Digital

Once the decision has been made to transition from an analog input device to a digital input, the user must identify what needs to interface from the SoC to the digital audio amp, instead of the external DAC found in conventional analog configurations.

When specifically transitioning from the TPA3116D2 to the TAS5828M, the user must determine which device control mode to use. Both devices contain a hardware mode with fixed configurations, but only the TAS5828M contains a software mode for greater customization. If software mode is being used, the user needs an I2C interface to select a configuration and modify device control and process flow registers, allowing for use of features such as Class-H control, DSP processing, tuning, and so forth.

Evaluation of these features and the resulting register configurations can be done using PurePath Console 3 (PPC3), TI’s tool for getting started on audio products. Once the evaluation module (EVM) is configured, the PPC3 GUI allows for an easy transition. PPC3 allows customization and testing of the DSP processing system, the Class-H control, and other configuration options.

Download the TAS5828M EVM application (Figure 1-4), select the configuration (Figure 1-5), and begin customizing the device. For additional information on PPC3, refer to the training videos on PPC3, and for tuning guidance see the General Tuning Guide for TAS58xx Family application report, all found on TI.com.

Figure 1-4 PurePath Console 3 TAS5828M EVM Application

Figure 1-5 Speaker Configuration and Tuning

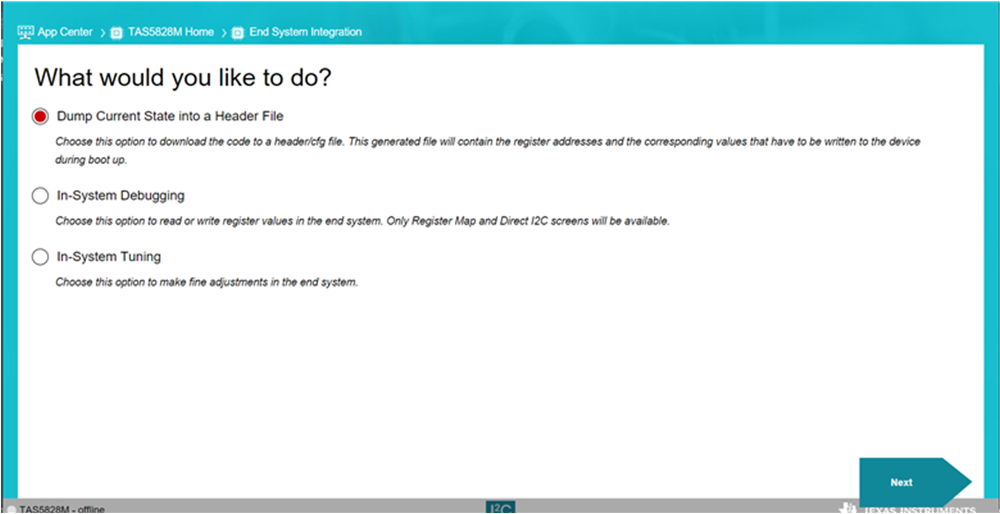

Once the configurations are set, the user can download a header file that contains all the data about the state of the device, using the End System Integration module in PPC3 shown in Figure 1-6 and Figure 1-7.

Figure 1-6 TAS5828M EVM Application Home Screen

Figure 1-7 Saving the Header File

The user then needs to initialize the file in their program, and it is ready to use. Unlike the TPA3116D2, the TAS5828M utilizes PPC3 for a simple method to test and configure the EVM. The ease of use of the PPC3 is one of the many tools TI offers to make the switch quick and easy.

In summary, understanding the system and the differences between the devices is the first step in transitioning from analog to digital input for any system. While it may not be well-suited for all systems, the TAS5828M provides higher efficiency, reduces the number of external components, and utilizes PurePath Console 3 to simplify the testing and configuration process. Regardless of which input signal is selected, the TPA3116D2 and the TAS5828M, or other audio amplifiers in TI’s portfolio, are all great options for your system.

Software mode allows the user to configure the device using I2C. This allows the user to modify both device configuration registers and process flow registers to set up the device for the desired application.

Hardware mode sets the device for default register configurations and bypasses the audio processing for a fixed implementation of the device.