-

Advanced Power-Converter Features for Reducing EMI SLUP408 February 2022 LM25149-Q1 , LM61460-Q1 , LM61495-Q1 , LMQ61460-Q1

-

Advanced Power-Converter Features for Reducing EMI

- 1 Introduction

- 2 Defining EMI

- 3 What Causes EMI in a Switched-Mode DC/DC Regulator?

- 4 Existing Passive EMI Filtering Techniques

- 5 Passive Filter Limitations

- 6 AEF

- 7 Spread Spectrum

- 8 DRSS

- 9 True Slew-Rate Control

- 10HotRod™ Package Technology

- 11Optimized Package and Pinout

- 12Integrated Capacitors

- 13Conclusions

- 14References

- 15Important Notice

- IMPORTANT NOTICE

Advanced Power-Converter Features for Reducing EMI

1 Introduction

The electrification of everything has introduced electronics to many applications in the world around us. Communications, transportation, factory automation and control, personal electronics, and health care are the most recognizable examples of electronics integration, while software innovation relies on the underlying hardware infrastructure.

With more electronic and computer systems used in smaller and tighter spaces, EMI becomes an increasing focus for system design. Switched-mode power supplies (SMPSs) are the most efficient way to power electronic systems, but they generate a significant amount of EMI. Increased switching speeds and switching frequencies result in higher power density but also tend to make EMI worse.

2 Defining EMI

EMI occurs when electric or magnetic fields couple and interfere between two or more electronic devices or systems. In an electronic system, voltage ripple can result in conducted noise propagating from one circuit to another, especially when there are shared connections such as power-supply rails.

In a simple example, imagine hearing audible noise in a radio system that goes away when removing or replacing a faulty device. That device could have been generating ripple, causing interference within the audible range and coupling to the audio output.

In a broader sense, EMI is not limited to audible noise and can interfere with power, system inputs, processing and system outputs. International EMI standards such as Comité International Spécial des Perturbations Radioélectriques (CISPR) 25 specify EMI amplitude limits for different frequencies [1]. In Figure 2-1, conducted noise amplitude is represented on the Y axis in decibel microvolts; frequency is represented on the X axis in megahertz. The graph plots CISPR 25 noise-limit lines with peak-level detector limits in red and average levels in blue. Noise detected using a specific test setup and equipment specified by the CISPR standard must remain below these limit lines.

Figure 2-1 Conducted EMI plot with CISPR

25 limits.

Figure 2-1 Conducted EMI plot with CISPR

25 limits.3 What Causes EMI in a Switched-Mode DC/DC Regulator?

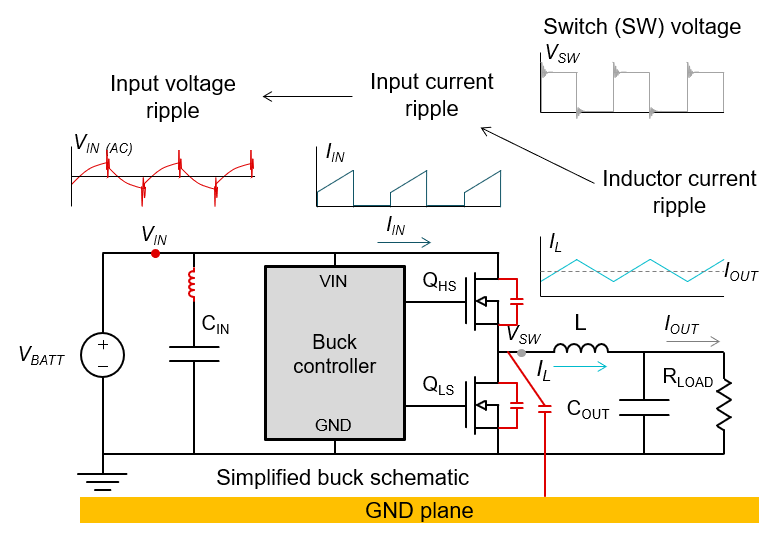

In battery-powered systems (see Figure 3-1), a switched-mode power supply like a buck converter commutates a switch node between a low voltage (GND) and an input voltage. Filtering the switch-node voltage generates an average DC output voltage, which is between the input voltage and GND in the case of a buck converter. The switching causes input ripple at the fundamental switching frequency, and the square edges result in higher-frequency harmonics. Sharper edges with faster slew rates generate higher-frequency harmonic energy. The trapezoidal input current ripple is discontinuous and exhibits the same high-frequency components in the current ripple.

Parasitic capacitances and inductances are nonideal properties of components in the circuit. These parasitics interact negatively with the voltage and current and generate very-high-frequency spikes and ringing noise. On the other hand, jitter and dithering (spread spectrum) can create low-frequency oscillation and noise. Figure 3-2 shows common frequency ranges where noise occurs from these sources.

Figure 3-1 Simplified buck controller

schematic and operating waveforms.

Figure 3-1 Simplified buck controller

schematic and operating waveforms. Figure 3-2 EMI frequency ranges for

spread spectrum and jitter, switching frequency and harmonics, and switch

ringing.

Figure 3-2 EMI frequency ranges for

spread spectrum and jitter, switching frequency and harmonics, and switch

ringing.This document discusses advanced power-converter features that improve upon existing methods to further reduce EMI. The five features entail the use of:

- An active EMI filter (AEF) to improve passive EMI filter performance.

- Dual-random spread spectrum (DRSS) to improve triangular and random spread spectrum.

- True slew-rate control to improve the series boot resistor technique.

- HotRod™ package technology to improve standard wire-bond connections.

- Integrated capacitors to improve external decoupling capacitor performance.