SLUUD32 June 2024 BQ41Z50

- 1

- Description

- Features

- 4

- 1Evaluation Module Overview

- 2BQ41Z50EVM Quick Start Guide

- 3Hardware

- 4Software

- 5Hardware Design Files

- 6Additional Information

- 7Related Documentation from Texas Instruments

2.3 EVM Connections

This section covers the hardware connections for the EVM. See Figure 3-1.

Figure 2-1 BQ41Z50 Circuit Module Connection to Cells and System Load or Charger

Figure 2-1 BQ41Z50 Circuit Module Connection to Cells and System Load or Charger- Direct connection to the cells: 1N (BAT–), 1P, 2P, 3P, 4P (BAT+)

Attach the cells as shown above in Figure 3-1. A specific cell connection sequence is not required; although, a good practice is to start with lowest cell in the stack (cell 1), then attach cells 2 through 4 in sequence. The U1 and U4 devices must not be damaged by other cell connection sequences, but there is a possibility that the BQ296103(U1) can blow the fuse. Attaching cells starting with cell 1 eliminates this risk. A short must be placed across unused voltage sense inputs. See Figure 3-2.

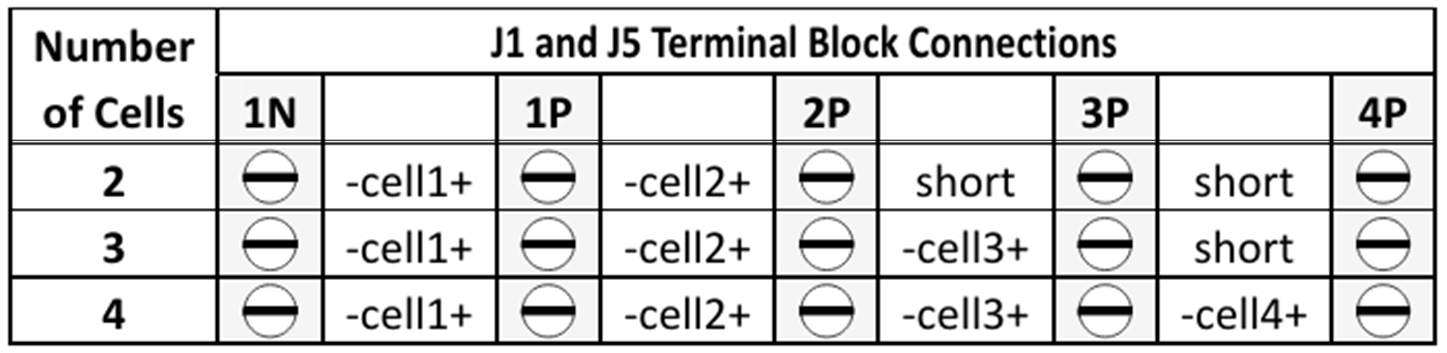

Figure 2-2 Cell Connection Configuration

Figure 2-2 Cell Connection ConfigurationA resistor cell simulator can be used instead of battery cells. Connect a resistor between each of the contacts on the J4 Jumper. For example, from 1N to 1P, from 1P to 2P, and so forth, until the desired number of cells has been achieved. A power supply can provide power to the cell simulator. Set the power supply to the desired cell voltage × the number of cells and attach the ground wire to 1N and the positive wire to 4P. For example, for a 3S configuration with a 3.6V cell voltage, set the power supply to 3 × 3.6 = 10.8V.

- Serial communications port (SMBC, SMBD)

Attach the communications interface adapter cable to J3 and to the SMB port on the EV2400.

- System load and charger connections across PACK+ and PACK–

Attach the load or power supply to the J1 terminal block. The positive load or power supply wire must be connected to at least one of the first two terminal block positions labeled PACK+. The ground wire for the load or power supply must be connected to the last terminal block positions labeled PACK–. See Figure 3-1

- System-present pin

(PRES/SHUTDN)

To start charge or discharge test, connect the PRES/SHUTDN position on the J 1 terminal block to PACK–. The PRES/SHUTDN can be left open if the non-removable (NR) bit is set to 1 in the Settings:Configuration:DA Configuration register. To test sleep mode, disconnect the PRES/SHUTDN pin.

- Wake-up the device up from shutdown (WAKE)

Press the Wake pushbutton switch to temporarily connect Bat+ to Pack+. This applies voltage to the PACK pin on the BQ41Z50 to power-up the regulators and start the initialization sequence.

- Parameter setup

The default data flash settings configure the device for 3-series Li-Ion cells. The user must change the Settings:Configuration:DA Configuration register to set up the number of series cells to match the physical pack configuration. This provides basic functionality to the setup. Other data flash parameters must also be updated to fine tune the gauge to the pack. For help with setting the parameters, see BQ41Z50 Technical Reference Manual.