SLVAFU8 July 2024 TPSI2072-Q1 , TPSI2140-Q1 , TPSI3050 , TPSI3050-Q1 , TPSI3052 , TPSI3052-Q1 , TPSI3100 , TPSI3100-Q1

4.1.2.2 Package Size

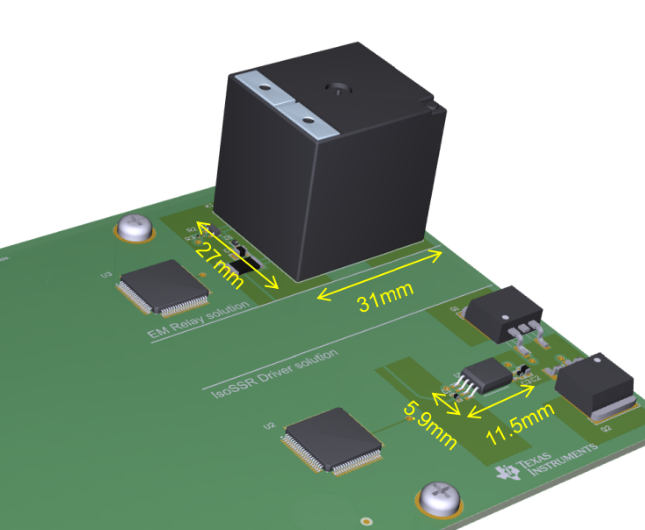

Electromechanical relays usually have larger heights than solid-state relays. This is because the the package needs to accommodate space for all of the parts within the device, such as the metal contacts, coil, and spring.

Figure 4-2 compares the package size of an electromechanical relay and an isolated switch driver.

Figure 4-2 Electromechanical Relay's

Package Size

Figure 4-2 Electromechanical Relay's

Package Size