SLVAFW2 July 2024 TDA4VM-Q1

Robotic system designers are faced with growing design complexity as they strive to meet the demand for robots with higher levels of automation. This increased complexity is especially prevalent in robots that closely collaborate with humans like collaborative robots (cobots) and autonomous mobile robots (AMR), shown in Figure 1. To ensure reliable operation with and near humans, these robots require even more electronic components. As a result, the embedded processors in these robots are becoming more complex, having to analyze and respond to a growing amount of data within the system for capabilities like perception, navigation, and motion control.

Figure 1 Autonomous Mobile Robot in a

Warehouse Environment

Figure 1 Autonomous Mobile Robot in a

Warehouse EnvironmentWhen it comes to working with these embedded processors, some companies don’t have the in-house resources and expertise required to develop hardware and software to fully support the processors in their system from the ground up. On the other end of the spectrum, companies that have more in-house resources and expertise, there is a major time investment required to develop hardware and software resources that could be better spent on further research and development of new products.

In order to reduce design costs and complexity, designers can work with Texas Instruments and its extensive ecosystem of third-party partners that specialize in “ready-to-deploy” hardware components. TI also provides software and design resources that help further streamline development of robotic applications including software development kits and easy-to-use, cloud-based tools for developing, benchmarking, and deploying artificial intelligence (AI) models.

This article explores how robotic system designers can streamline their development processes and get to market faster with TI’s extensive, cultivated third-party network as well as available design resources and easy-to-use software from TI.

While many robotic systems benefit from “ready-to-deploy” hardware resources, especially those for motor control, communications, and functional safety, this article will primarily focus on resources for vision processing applications, highlighting a few of TI’s hardware partners. Visit the TI Partner Directory to learn more about TI’s partner ecosystem.

Simplifying Robotic Designs With Third-Party Hardware Modules for TI Application Processors

Cobots and AMR continue to grow in popularity as modern manufacturing and global supply chains require enhanced productivity and control. In manufacturing environments in particular, these robots can enhance operational efficiency by enabling greater collaboration with humans and other robots while also allowing humans to focus on higher-priority tasks.

While the benefits of these robots may be straightforward, their design can be complex – especially when implementing vision processing systems that use analytics capabilities and deep learning at the network edge. Developing camera modules and then testing and deploying AI models in cobots and AMRs can be time intensive and requires specific programming expertise and specialized software.

To expedite development of vision processing in Arm®-based designs with space constraints, designers can use modules from TI’s third-party hardware partners like the TechNexion ROVY-4VM system on module (SoM), the smart mobility architecture (SMARC) module, conga-STDA4, from Congatec, the BeagleBone AI-64® and the Arducam V3Link™ Camera kit.The TechNexion, Congatec and BeagleBone modules are based on the TDA4VM processor, which features a heterogenous architecture with dual Arm Cortex®-A72, DSP, and accelerators for deep learning in vision-based applications.

TechNexion ROVY-4VM

Using a SoM like the TechNexion ROVY-4VM, designers can develop their AMR product around a module that simplifies the design process. The ROVY-4VM integrates the processor, power management ICs (PMICs), and memory (DDR, UFS, SPI NOR Flash) on a single PCB that is fully tested and production-ready, with all the remaining peripherals of the processor conveniently routed to board-to-board high density interconnects (HDI). While the designer is free to design a carrier board from scratch with their selected features, TechNexion created the ROVY-4VM-EVK, which is a complete AMR-focused kit for the ROVY-4VM (as shown in the AMR demo in Figure 2). This kit can be used as a reference design to quickly enable features like adding up to 8x plug-and-play cameras using FPD-Link™ III technology (TECHN-3P-VLS3-X-SL), adding a display (also with FPDLink III), expanding Ethernet ports with standard or single-pair ethernet, and easy-to-access standard USB3/Gb Ethernet ports for rapid prototyping and development.

Figure 2 TechNexion “Rovybot” AMR Demo,

ROVY-4VM-EVK With Chassis

Figure 2 TechNexion “Rovybot” AMR Demo,

ROVY-4VM-EVK With ChassisCongatec conga-STDA4

Using the conga-STDA4, designers can leverage the open-standard SMARC module form factor and pinout from SGeT to enhance features like functional safety and add native analytics with ARM-based processors and Linux-based software. Many Industrial applications used in factory automation today are based on SMARC modules. As an open standard supported by a large community of developers, the SMARC form factor is easy to design with and scalable across designs since aspects of existing carrier boards can be reused such as carrier board routing and peripheral sets used for DIN-rail mounted IPCs, often only needing a simple module exchange. This allows enhanced ease of use, helping designers more easily update existing designs, reducing total system cost and size while also leveraging the advanced feature set of TDA4VM processors.

BeagleBone AI-64 and ArduCam

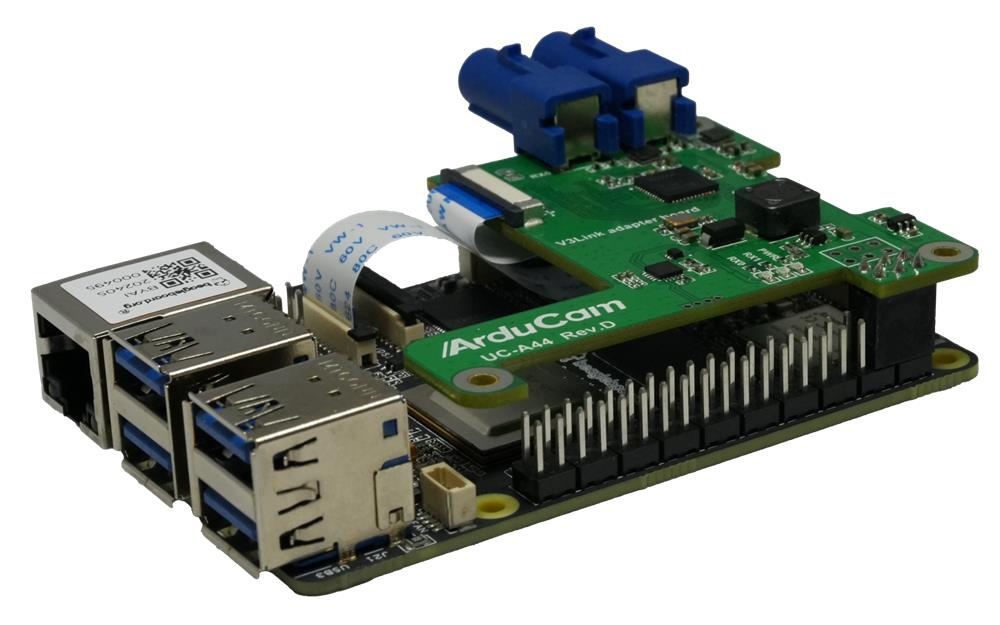

The BeagleBone AI-64 from the BeagleBoard.org Foundation is another option for early development of vision processing in robotics systems. Based on the TDA4VM, the BEAGL-BONE-AI-64 is a complete system that can use the Debian OS and can be combined with a ARDCM-3P-V3LINK-CAM V3Link Camera kit from ArduCam, as shown in Figure 3, to simplify vision processing designs and help designers learn how to control robots. For users coming from the Raspberry Pi ecosystem, Beagle AI® (based on the AM67A processor) may be more familiar and is also compatible with the ArduCam kit to quickly develop and test multi-camera vision processing for their specific application.

Figure 3 ArduCam V3Link

Camera Kit

Figure 3 ArduCam V3Link

Camera KitSimplifying Robotic Vision Processing With Intuitive Software and Development Resources

Along with “ready-to-deploy” hardware, robot system designers also need intuitive, user-friendly software to streamline development. This software enables more efficient control, coordination, and execution of tasks. The more intuitive the software, the easier it is for engineers to design, program, and troubleshoot robotic systems.

User-friendly software reduces the learning curve, allowing engineers to focus more on the application's functionality rather than grappling with complex software interfaces or taking additional training. When using TI processors for vision processing designs, robotic system designers have access to a full suite of software and web-based tools and development resources including:

- Software development kit (SDK) for the

TDA4VM

The SDK for the TDA4VM is a unified software platform that scales across different system-on-chip (SoC) devices for easier implementation and code reuse. The SDK provides a flexible software platform that can help simplify and accelerate the development of robotics applications that feature AI-powered vision processing and real-time processing capabilities. The SDK comes with extensive documentation and a comprehensive set of software, including drivers, middleware, and application examples, which can significantly accelerate the development of robotics applications.

- TI Robotics software development kit (SDK)

for TDA4VM and AM6xA application processors

The TI Robotics SDK is designed to support the development of robotics applications on TDA4VM and AM6xA application processors. It features software components, libraries, and tools to facilitate the development of robotics applications, including real-time control, 3D graphics, image, and video processing. It also includes examples and documentation to help developers get started.

- Edge AI Studio

Edge AI Studio is a collection of web-based tools designed to simplify and accelerate the creation of edge AI applications. It provides a user-friendly interface for developing, training, and deploying machine learning models on TI processors. The Model Composer, Model Analyzer, and Model Maker tools in Edge AI Studio are beneficial for designers and developers working on AI applications that require real-time processing at the network edge.

Edge AI Studio is useful for designers who may not have extensive experience in developing machine learning models, as it provides a simplified, graphical interface for developing AI applications using remote TI hardware. It also includes pre-trained models and allows for the customization of these models.

Conclusion

Innovations in embedded processors and the third-party hardware that supports them will continue to push the boundaries of what's possible in robots. While we’re already seeing some of these capabilities in a variety of industries, the ability to process and analyze vast amounts of visual data in real-time with advanced vision processing components will help robots more reliably and safely react to split-second decisions and adapt to dynamic situations. From collaborative robots working even closer with humans in factories and warehouses, to autonomous vehicles and drones that can safely navigate city streets and deliver goods, robots will continue to transform the way our world works.