SLVUCC6 March 2022 TPS629203-Q1

5 Test Results

This section provides the test results of the TPS629203-Q1EVM.

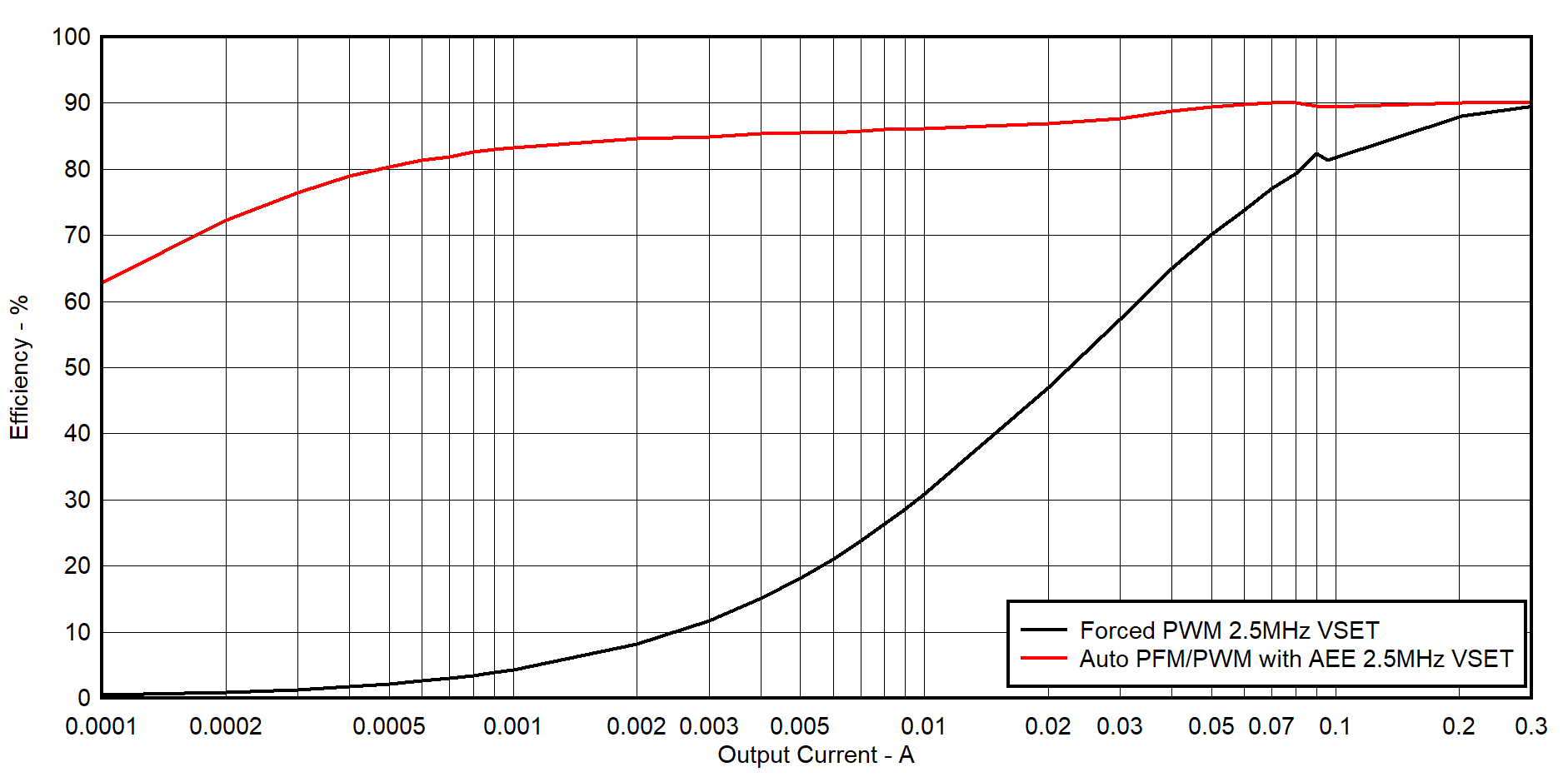

Figure 5-1 Efficiency, VIN = 12 V,

VOUT = 3.3 V, FSW = 2.5 MHz

Figure 5-1 Efficiency, VIN = 12 V,

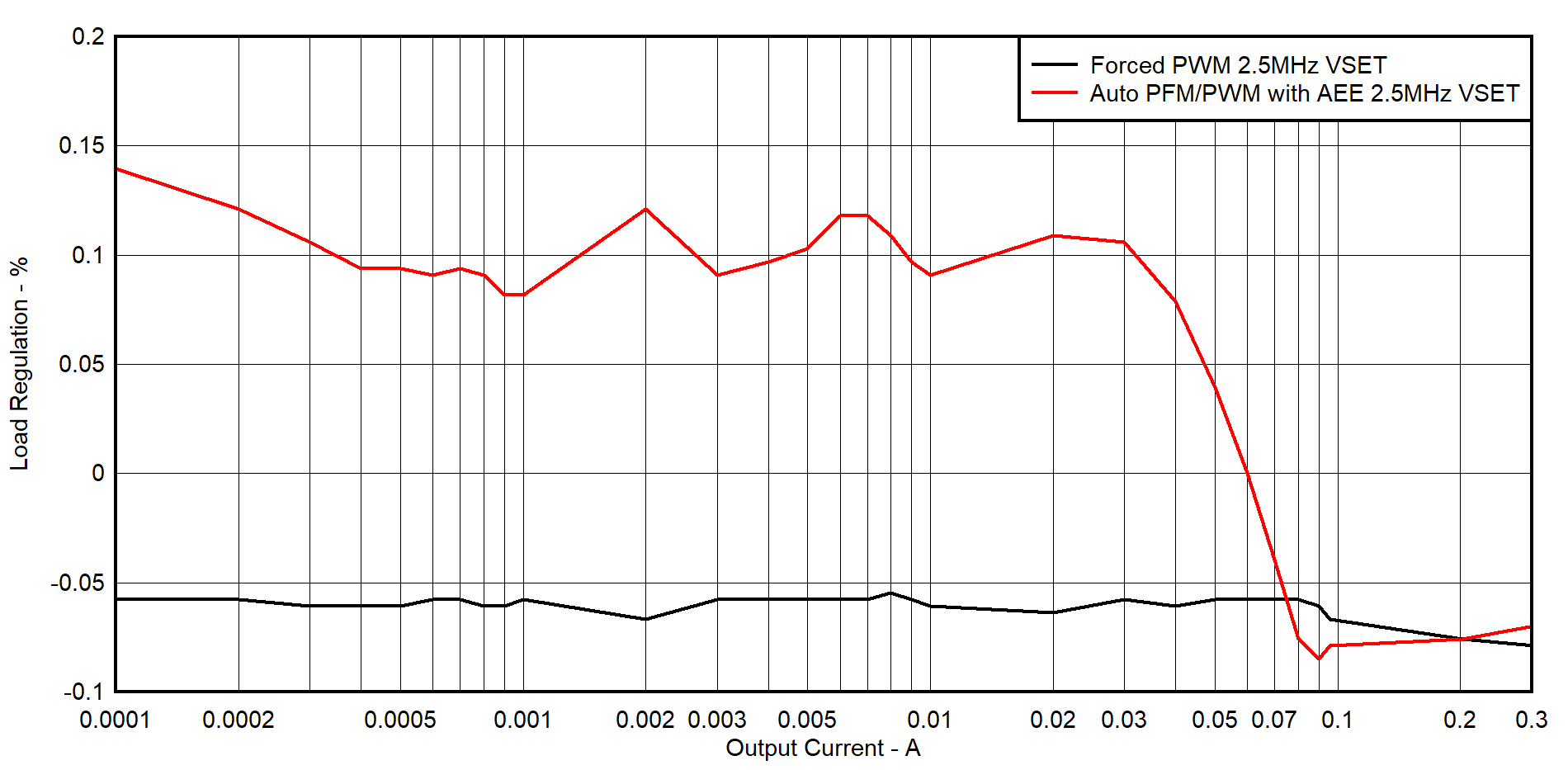

VOUT = 3.3 V, FSW = 2.5 MHz  Figure 5-2 Load Regulation, VIN = 12 V,

VOUT = 3.3 V, FSW = 2.5 MHz

Figure 5-2 Load Regulation, VIN = 12 V,

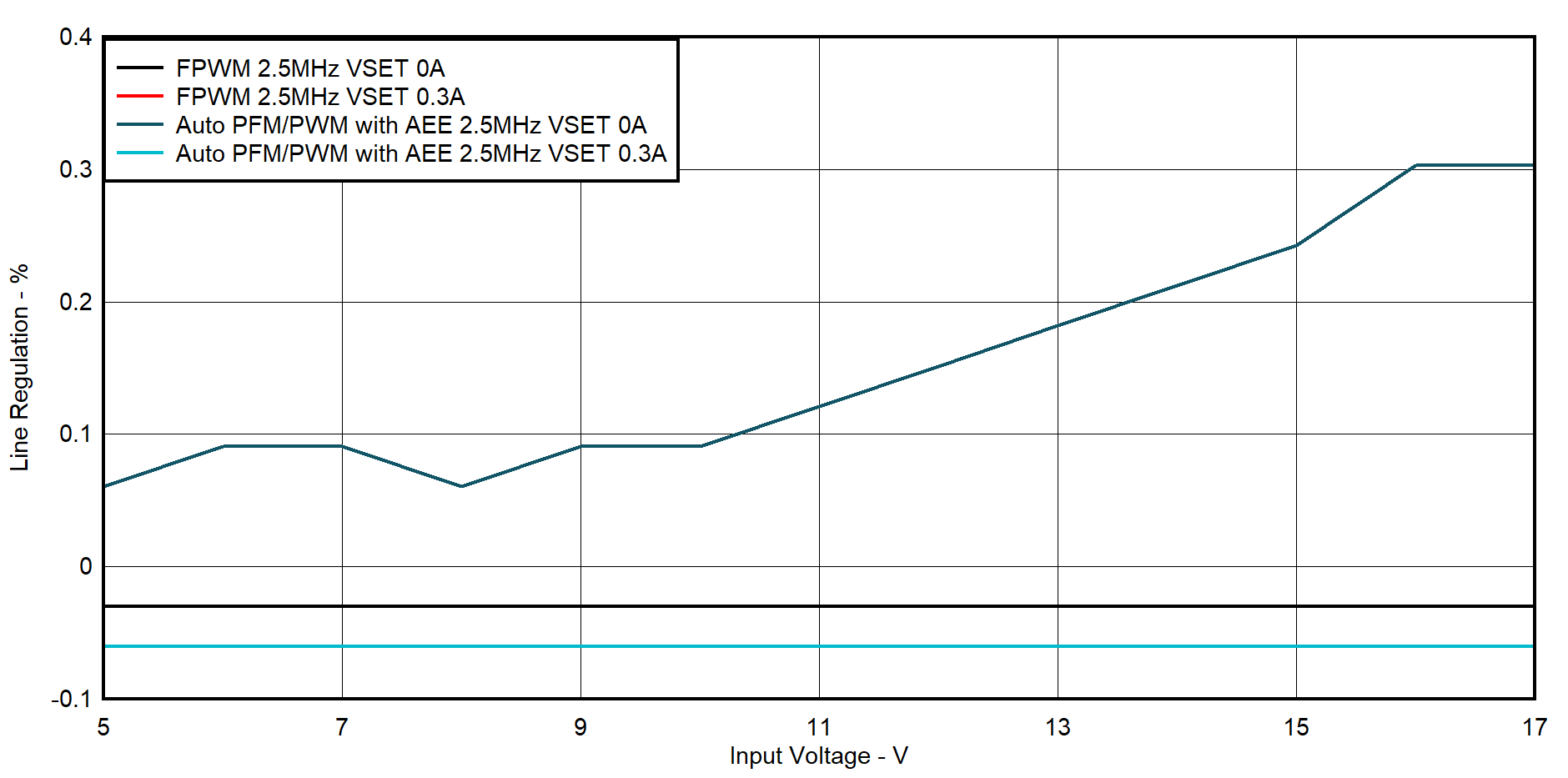

VOUT = 3.3 V, FSW = 2.5 MHz  Figure 5-3 Line Regulation, VIN = 5 V–17

V, VOUT = 3.3 V, IOUT = 0 A and 300 mA, FSW = 2.5

MHz

Figure 5-3 Line Regulation, VIN = 5 V–17

V, VOUT = 3.3 V, IOUT = 0 A and 300 mA, FSW = 2.5

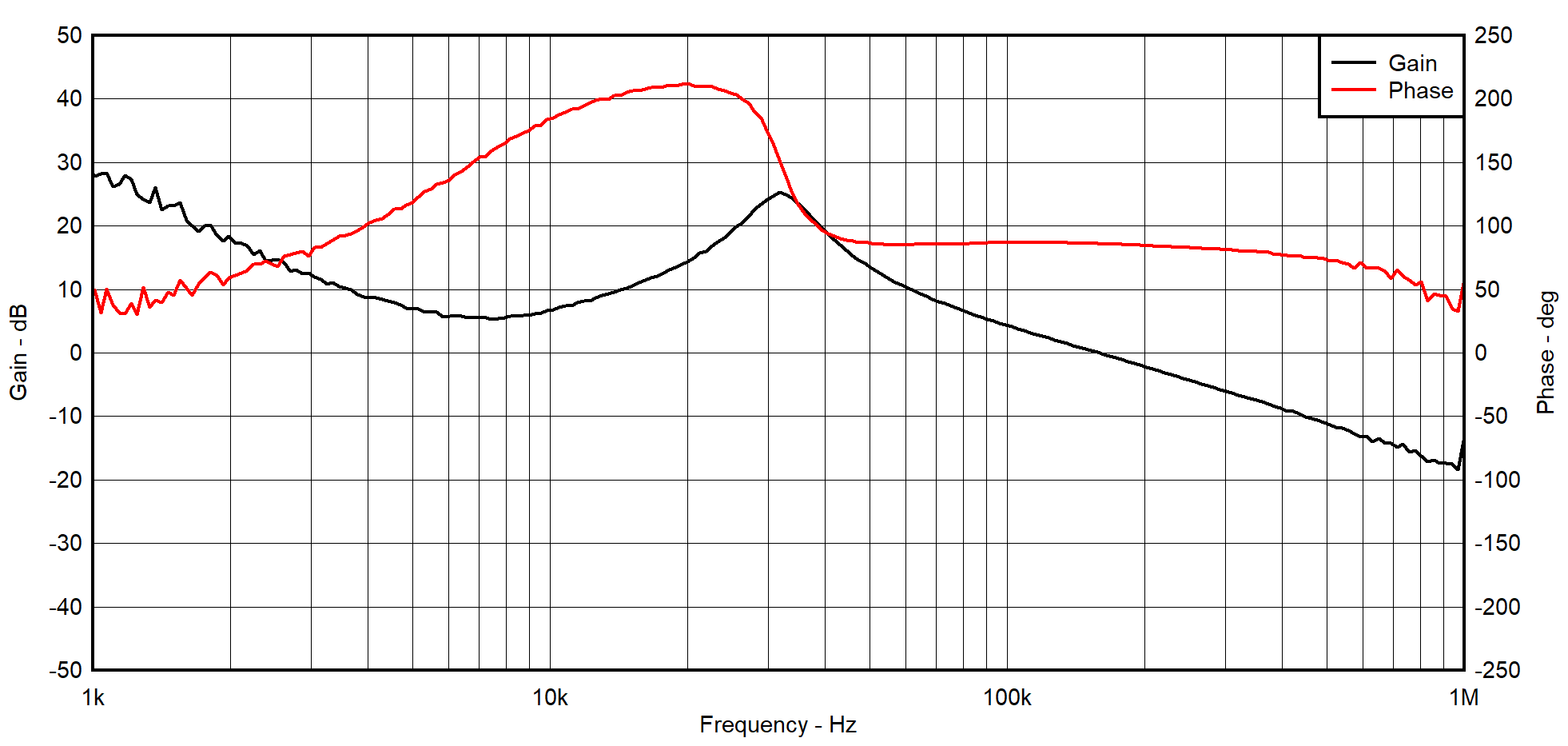

MHz Figure 5-4 Loop Response, Forced PWM VSET,

VIN = 12 V, VOUT = 3.3 V, IOUT = 300 mA

Figure 5-4 Loop Response, Forced PWM VSET,

VIN = 12 V, VOUT = 3.3 V, IOUT = 300 mA Figure 5-5 Output Voltage Ripple, Auto PFM/PWM,

VIN = 12 V, VOUT = 3.3 V, IOUT = 0 A

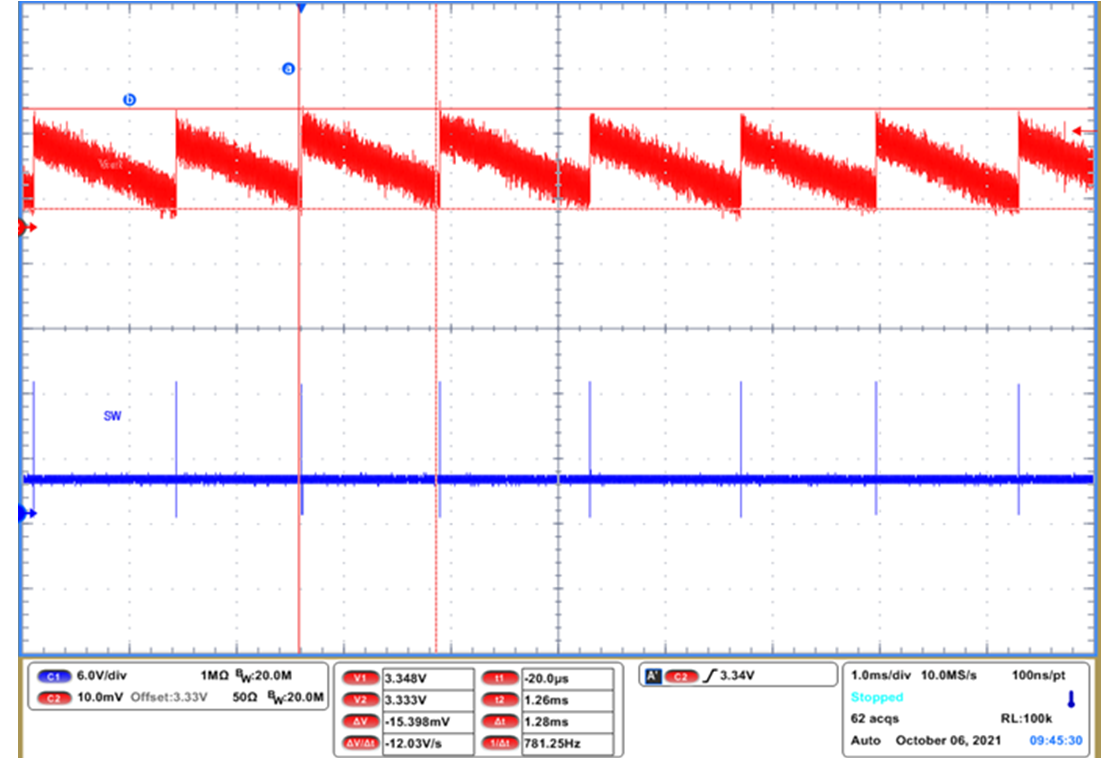

Figure 5-5 Output Voltage Ripple, Auto PFM/PWM,

VIN = 12 V, VOUT = 3.3 V, IOUT = 0 A Figure 5-6 Output Voltage Ripple, Forced PWM,

VIN = 12 V, VOUT = 3.3 V, IOUT = 300 mA

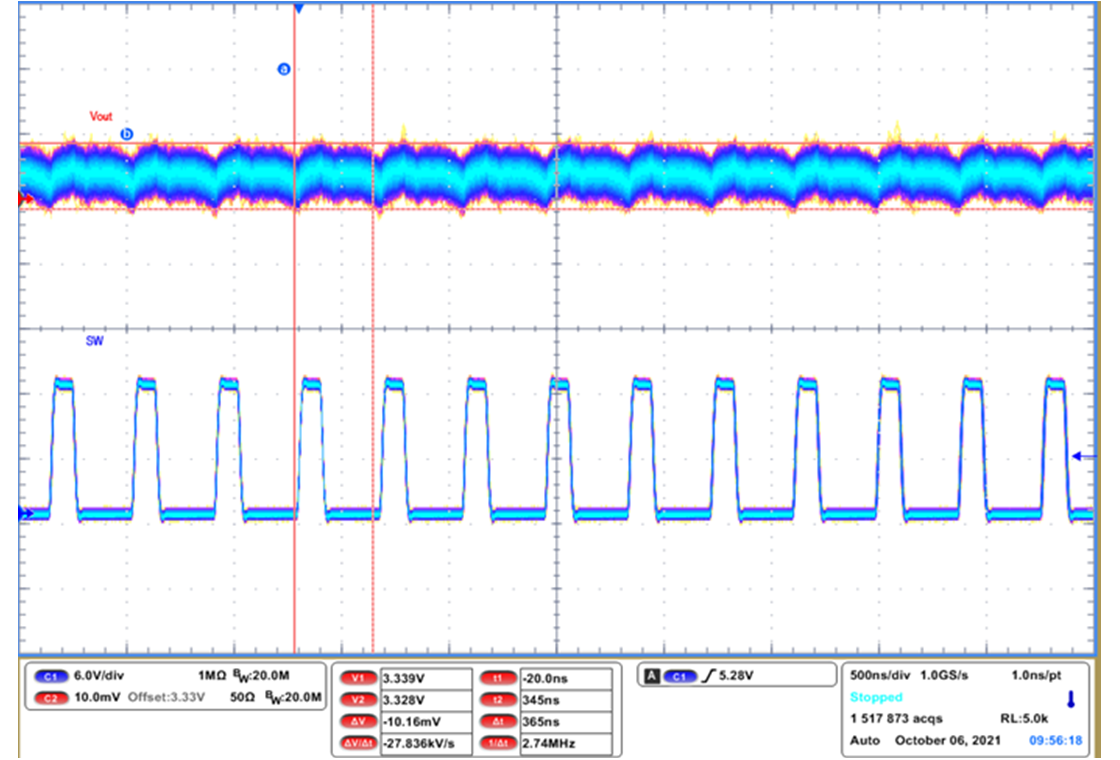

Figure 5-6 Output Voltage Ripple, Forced PWM,

VIN = 12 V, VOUT = 3.3 V, IOUT = 300 mA Figure 5-7 Input Voltage Ripple, Forced PWM,

VIN = 12 V, VOUT = 3.3 V, IOUT = 300 mA

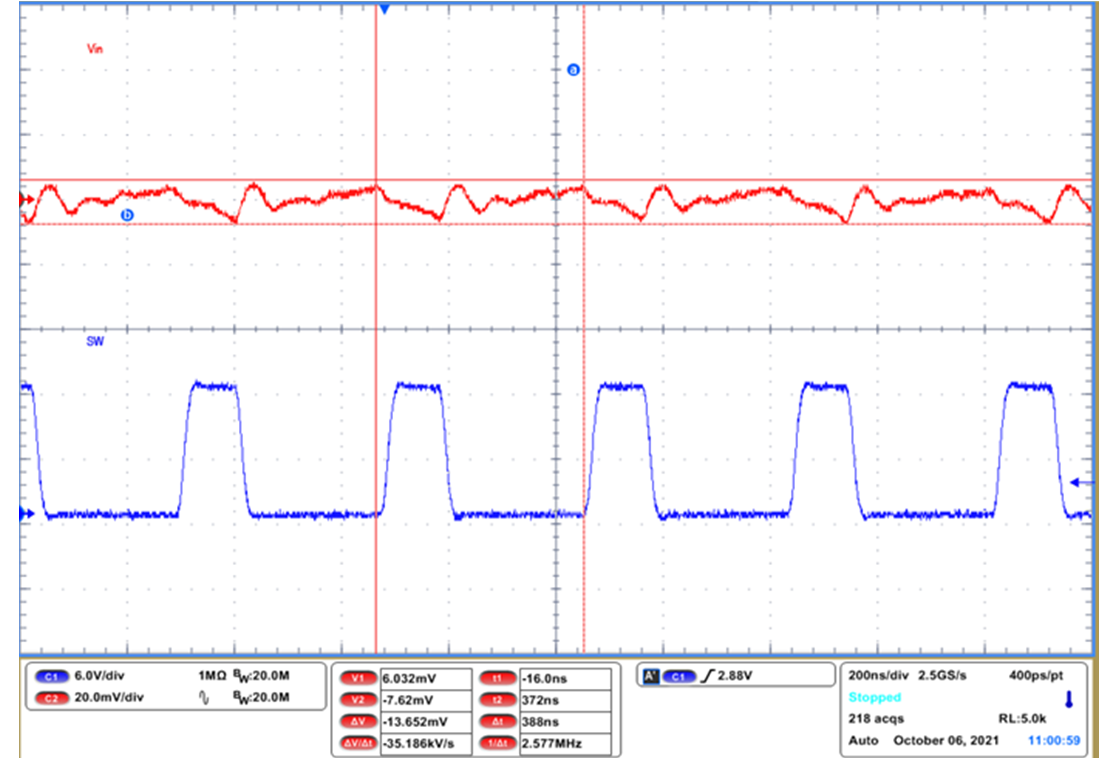

Figure 5-7 Input Voltage Ripple, Forced PWM,

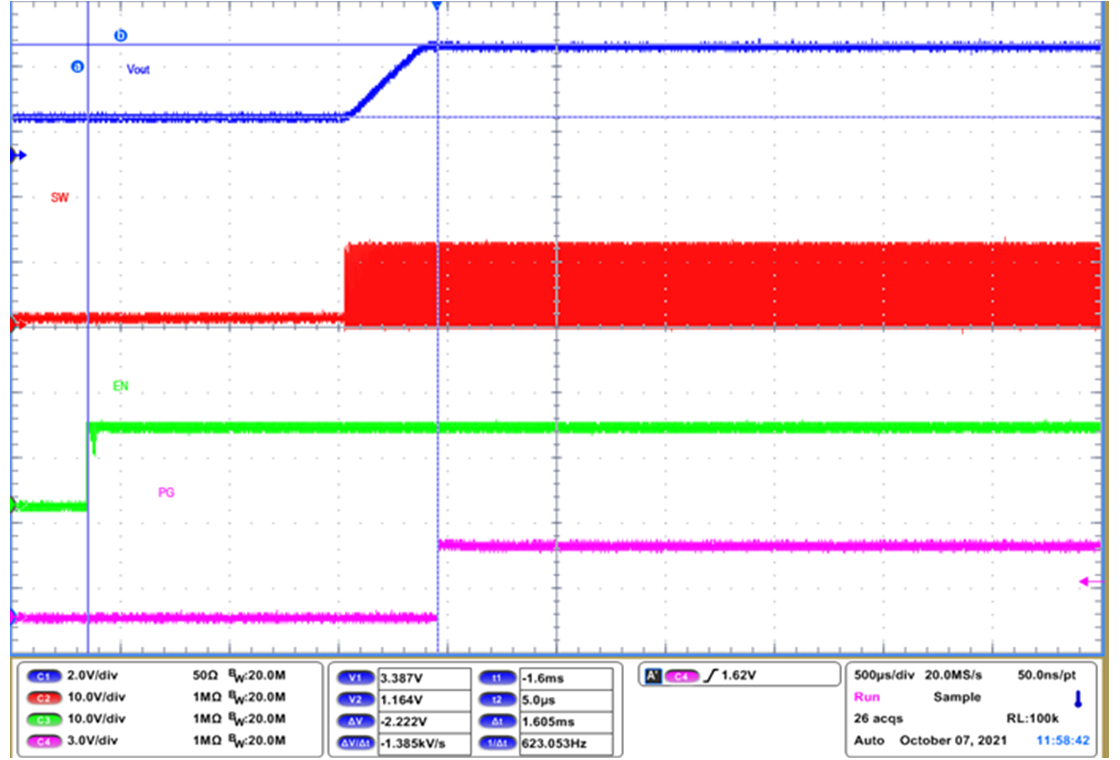

VIN = 12 V, VOUT = 3.3 V, IOUT = 300 mA  Figure 5-8 Enable Start-Up, Forced PWM,

VIN = 12 V, VOUT = 3.3 V, IOUT = 300 mA

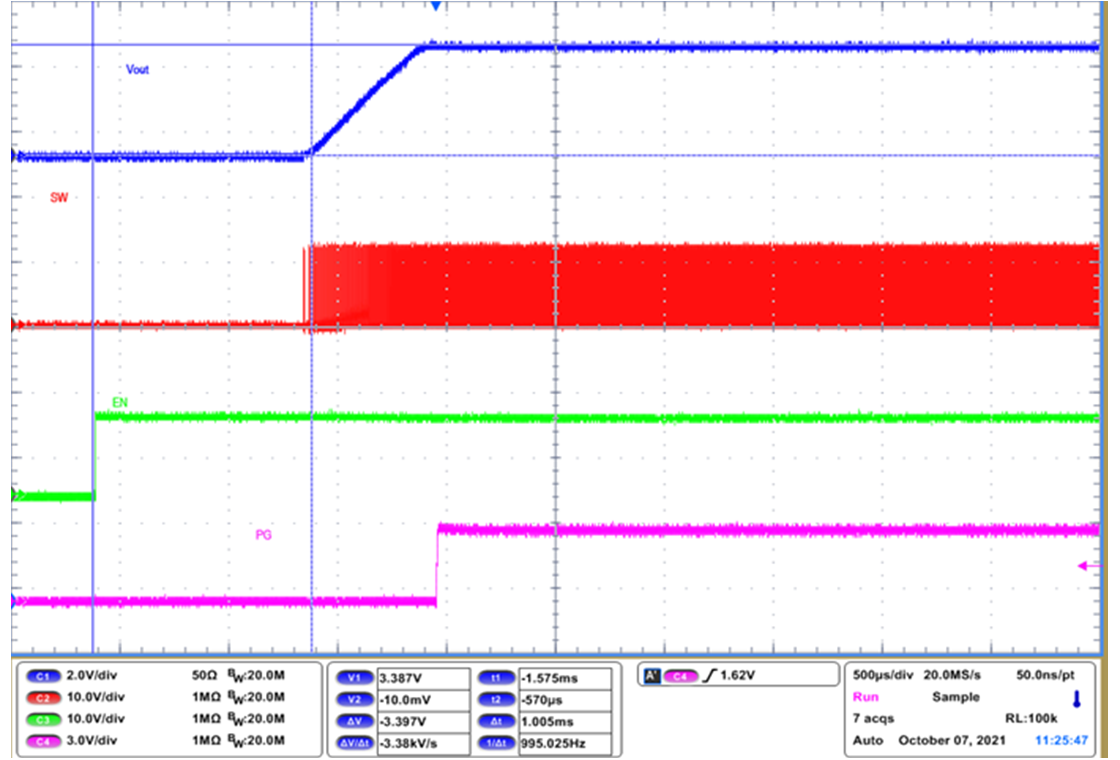

Figure 5-8 Enable Start-Up, Forced PWM,

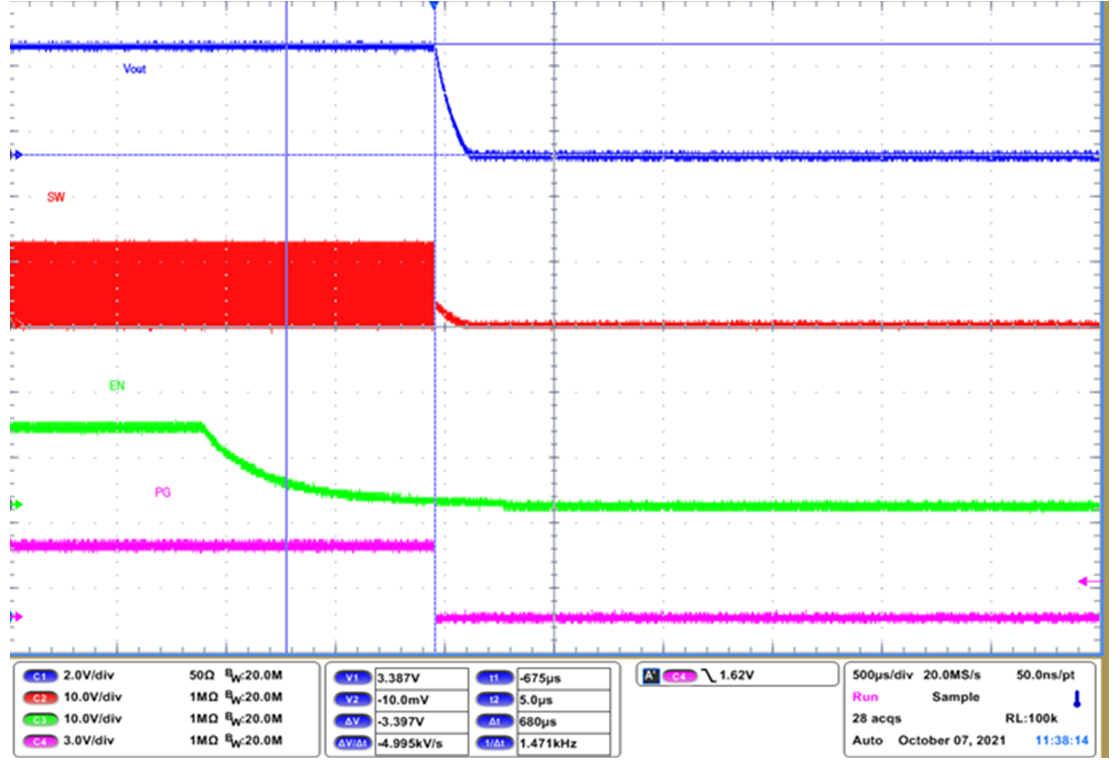

VIN = 12 V, VOUT = 3.3 V, IOUT = 300 mA Figure 5-9 Enable Shutdown, Forced PWM,

VIN = 12 V, VOUT = 3.3 V, IOUT = 300 mA

Figure 5-9 Enable Shutdown, Forced PWM,

VIN = 12 V, VOUT = 3.3 V, IOUT = 300 mA  Figure 5-10 Enable Prebias Start-Up, Forced PWM,

VIN = 12 V, VOUT = 3.3 V, IOUT = 0 A

Figure 5-10 Enable Prebias Start-Up, Forced PWM,

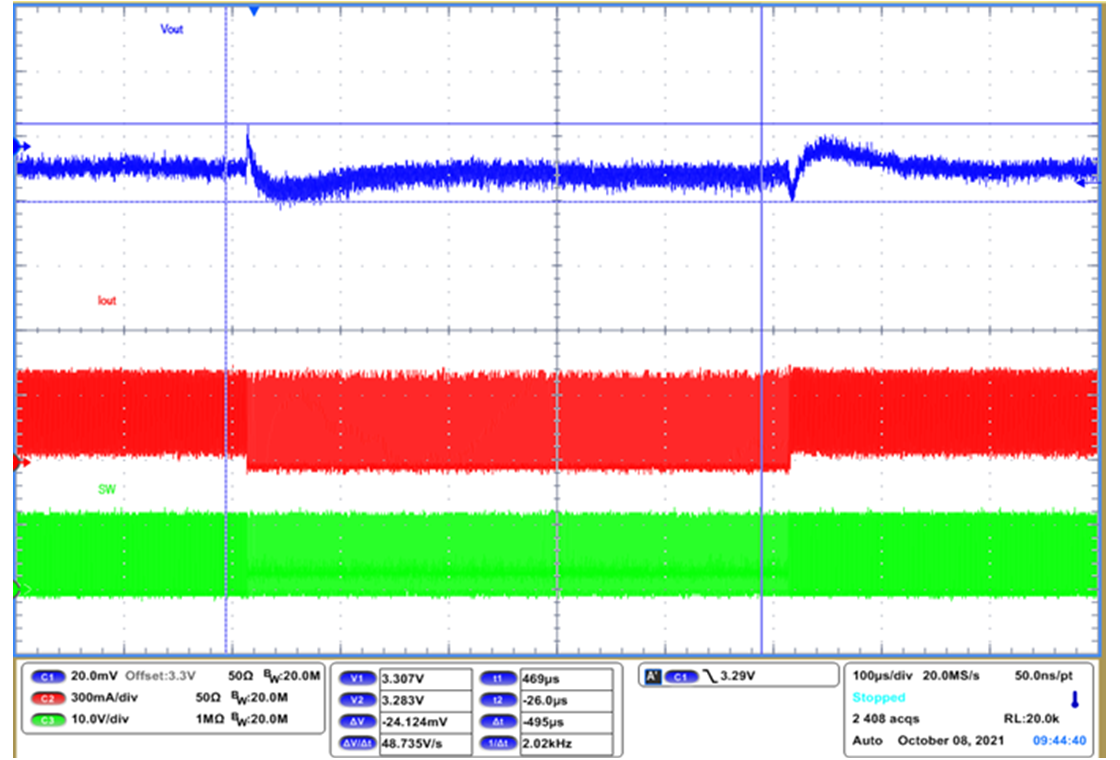

VIN = 12 V, VOUT = 3.3 V, IOUT = 0 A Figure 5-11 Load Transient, Forced PWM VSET,

VIN = 12 V, VOUT = 3.3 V, IOUT= 100 mA–300 mA, Slew Rate

= 1 A/μs

Figure 5-11 Load Transient, Forced PWM VSET,

VIN = 12 V, VOUT = 3.3 V, IOUT= 100 mA–300 mA, Slew Rate

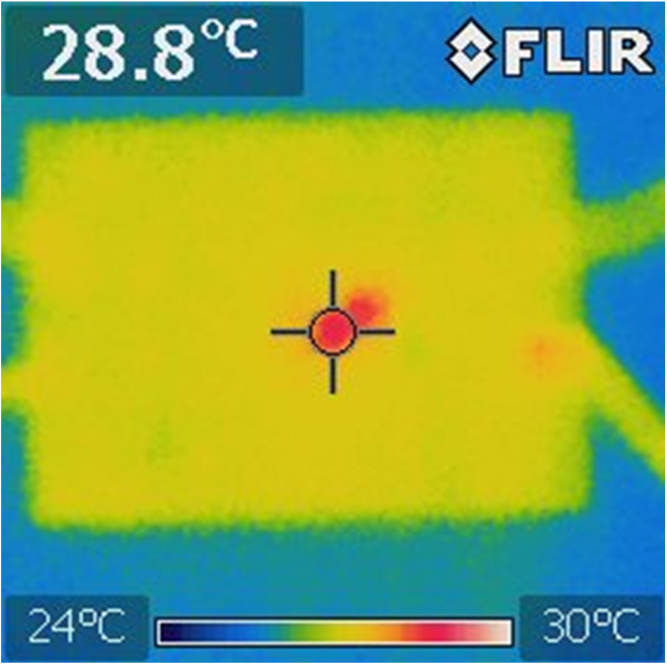

= 1 A/μs Figure 5-12 Thermal Performance, Forced PWM,

VIN = 12 V, VOUT = 3.3 V, IOUT = 300 mA, FSW =

2.5 MHz

Figure 5-12 Thermal Performance, Forced PWM,

VIN = 12 V, VOUT = 3.3 V, IOUT = 300 mA, FSW =

2.5 MHz