SLVUCG6 November 2022 TPS650350-Q1

- TPS650350-Q1 EVM User's Guide

- Trademarks

- 1 Introduction

- 2 Requirements

- 3 Operation Instructions

- 4 EVM Configurations

- 5 Test Points

- 6 Graphical User Interface

- 7 Typical Performance Plots

- 8 TPS650350-Q1 EVM Schematic

- 9 TPS650350-Q1 EVM PCB Layers

- 10TPS650350-Q1 EVM Bill of Materials

6.3 In-Circuit Programming

The TPS650350-Q1 EVM demonstrates the in-circuit programming capabilities of the TPS650350-Q1 PMIC in a typical application. This section provides an example in-circuit programming procedure with application considerations.

- Verify the desired power, sequence, and other settings using the GUI's Sequencing Overview tools. See Configuring the Power Sequence.

- Once settings are verified and validated, configure the TPS650350-Q1 EVM for a typical camera application:

- Ensure the I2C pull-up jumper is populated at J6.

- Supply the PMIC VIO with either the Buck 1 or Buck 2 output. See Selecting the Logic Supply Voltage.

- Tie the PMIC VSYS/PVIN_B1 input voltage to VIN. See Buck 1 Input Supply.

- Supply the PMIC Buck 2, Buck 3, and LDO with the Buck 1 output. See Selecting Regulator Input Supplies.

- Assert SEQ (S1) before applying power.

- Apply a Buck 1 input voltage (typical is 12 V) to power up the device. By default, the Buck 1 and Buck 2 regulators are enabled, allowing the 3.3 V and 1.8 V rails to power up.

- In a typical camera application, this may be sufficient to power up the serializer and enable PMIC programming over the Serializer-Deserializer (SerDes) back-channel.

- If additional rails are required, assert GPIO (S4) to enable the Buck 3 and LDO regulators.

- Unlock the configuration and control registers.

- Re-program the PMIC settings. If changing a regulator output voltage, TI recommends disabling the regulator first. If doing this in an application setting shuts down a critical component, change the output voltage in small steps to prevent triggering under or over-voltage fault handling.

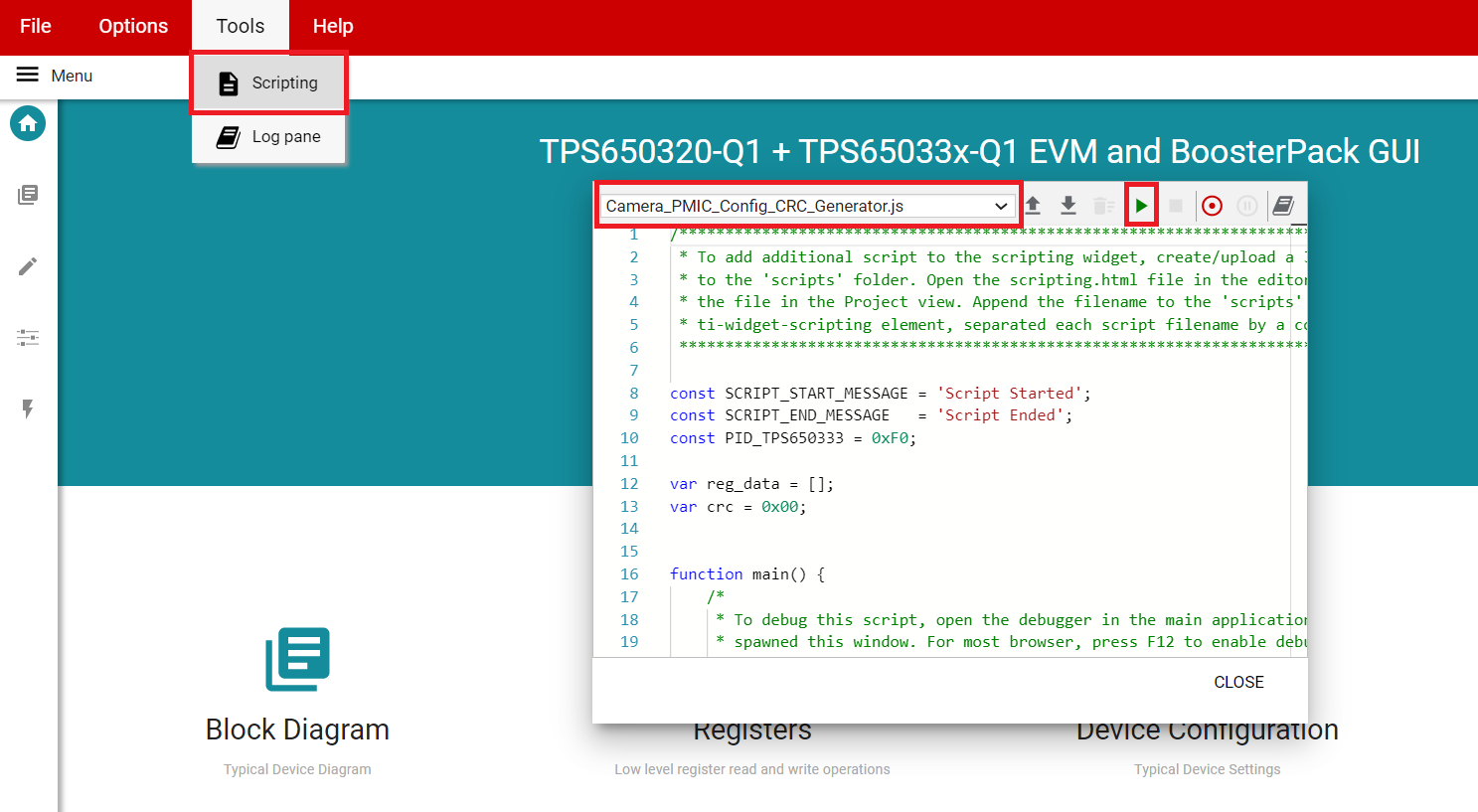

- If the device configuration Cyclic Redundancy Check (CRC) is enabled, calculate and write the new configuration CRC by running the GUI's built-in script. For more information on the GUI's capabilities for programming automation, see the BOOSTXL-TPS65033 User's Guide.

Figure 6-14 GUI Configuration CRC Script

Figure 6-14 GUI Configuration CRC Script - Burn the final PMIC register settings to EEPROM.

- Validate the settings on subsequent startups.