SLYA076 july 2023 TMAG5273

2.2 Ultrasonic

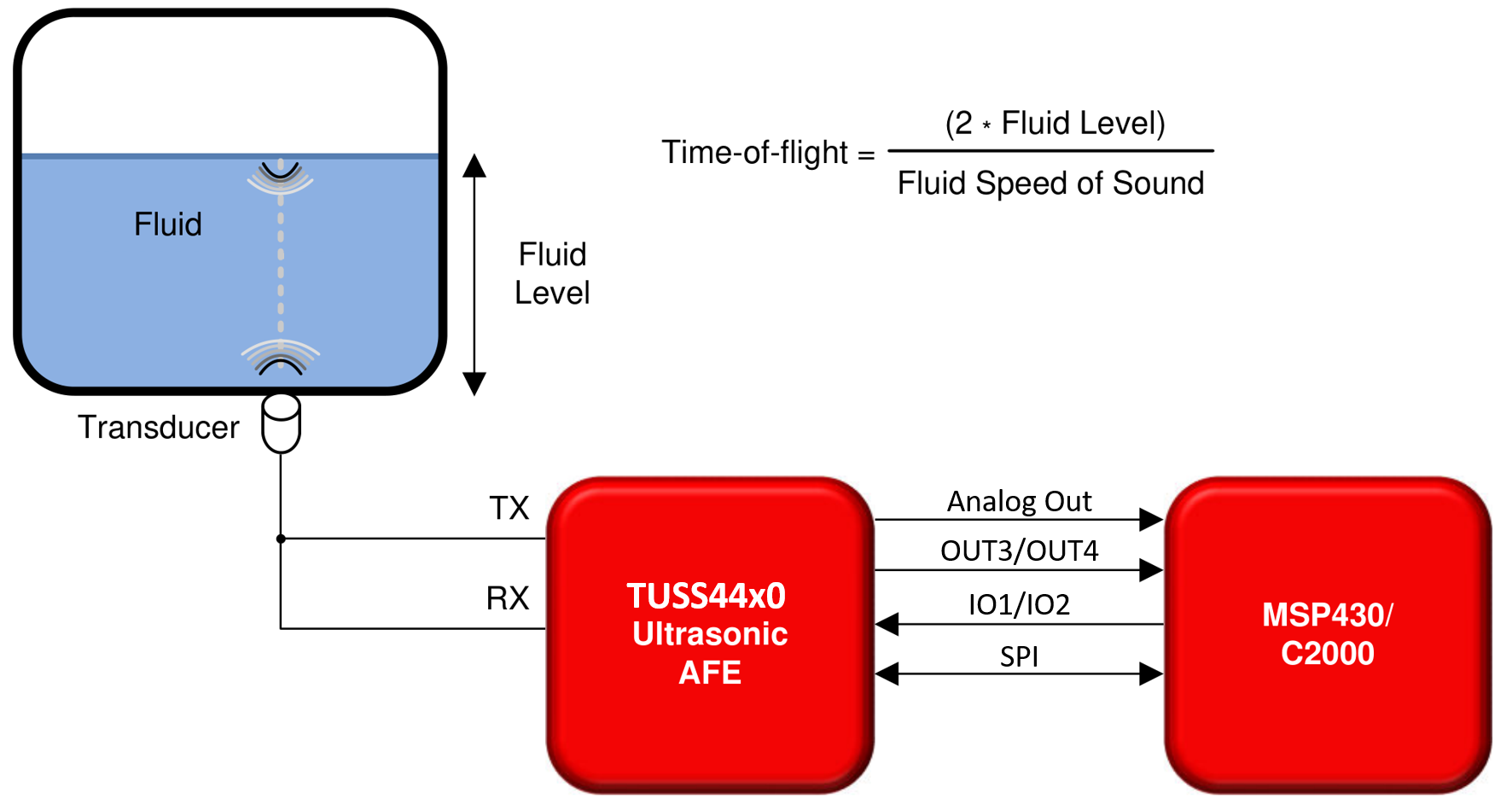

Ultrasonic level sensing relies on a series of pulses being sent from a transducer on one side of the tank and then listening for the return pulses that reflect off the top of the liquid. The time-of-flight (TOF) indicates the fluid level as shown in Figure 2-1.

Figure 2-2 Ultrasonic Liquid Level

Sensing

Figure 2-2 Ultrasonic Liquid Level

SensingUltrasonic sensing can produce accurate level readings, even down to the micrometer in certain conditions. Ultrasonic designs tend to be a more expensive sensing design compared to capacitive or Hall. The electrical properties of the liquid does not affect ultrasonic measurements compared to capacitive sensing designs. Air coupled vs water coupled ultrasonic sensing give similar performance but give flexibility in the transducer mounting location - above, below, or inside of the tank.

Ultrasonic Sensing Basics for Liquid Level Sensing, Flow Sensing, and Fluid Identification Applications application note provides more details on the ultrasonic implementation.