-

Multibattery management in medical ultrasound systems

- 1

- 1 Introduction

- 2 Understanding Battery Packs

- 3 Stackability Requirements for Battery Packs

- 4 A Multibattery Management System Design

- 5 Battery Charging

- 6 Battery Gauging and Protection

- 7 DC-to-DC Converter or Controller Stage (Boost or Buck-boost Stage)

- 8 ORing Control

- 9 Load Sharing

- 10Conclusion

- 11References

- 12Related Web Sites

- IMPORTANT NOTICE

Multibattery management in medical ultrasound systems

1 Introduction

Patients in a hospital intensive-care unit require constant monitoring with equipment that must have continuous power. Any loss of patient data is completely unacceptable in critical medical applications; plus, a power failure is likely to damage expensive electrical components in scanning equipment.

Medical ultrasound imaging is a diagnostic technique that enables the visualization of a person’s internal organs, including their size, structure and an estimate of their blood flow. Ultrasound scanners are available in premium, cart-based, portable and smart-probe versions, depending on the number of transmit and receive channels. Premium and cart-based ultrasound scanners are typically line-powered; however, they have multiple battery-packs to support backup power.

2 Understanding Battery Packs

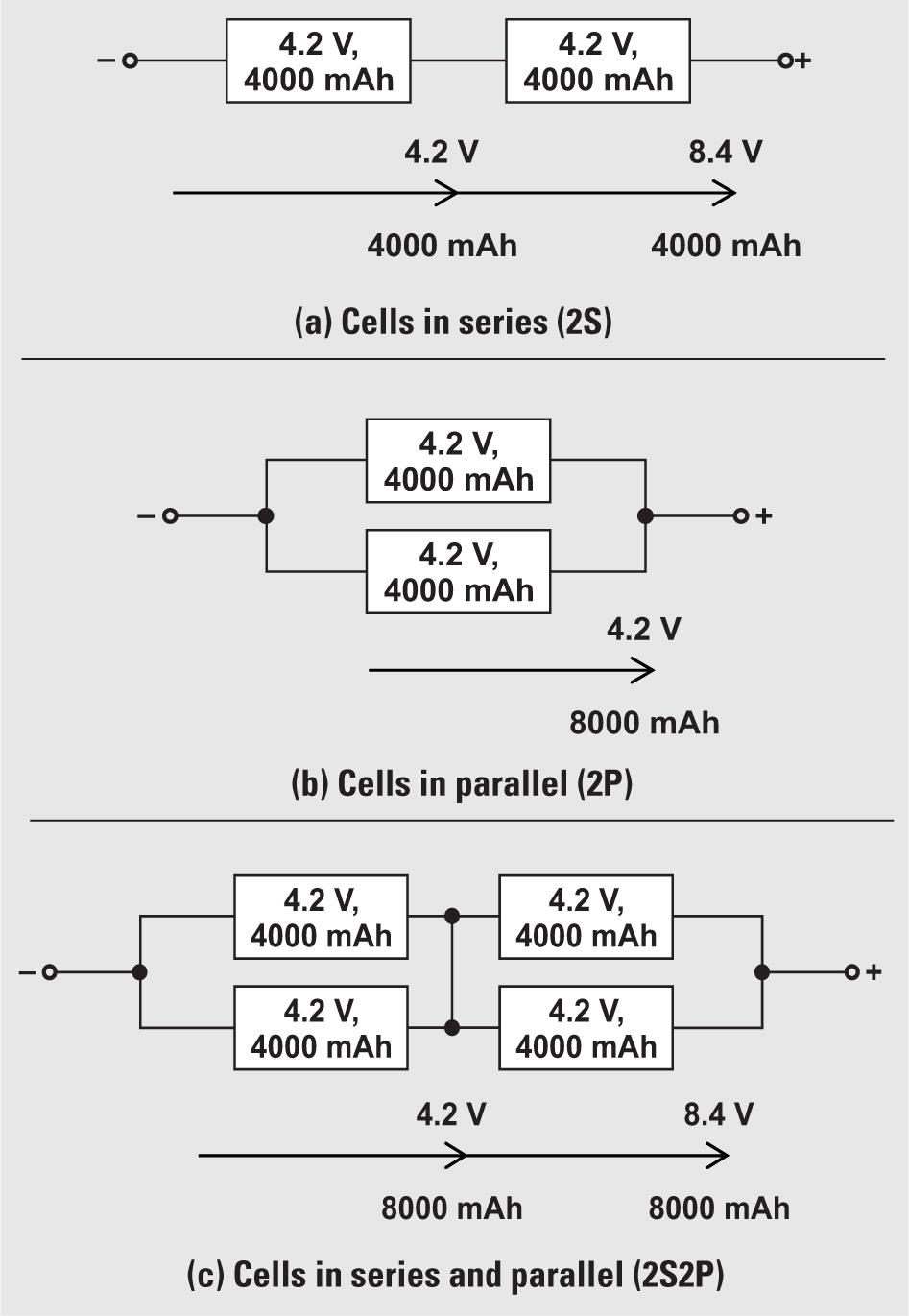

A single cell is a electrochemical source of electrical potential, or voltage. Its size and chemical type determine the cell’s nominal capacity and voltage rating, respectively. Battery packs achieve the desired operating voltage by connecting several cells in series; each cell adds its voltage potential to derive the total terminal voltage. A parallel connection of cells attains higher capacity by adding up the total ampere-hour ratings of the cells. Some packs comprise both series and parallel connections. For example, a battery pack with four cells in series and two cells in a parallel configuration is called 4S2P (4 series, 2 parallel); similarly, a 5S4P configuration has five cells in series and four cells in parallel.

Figure 1a shows a battery pack with two 4.2-V lithiumion (Li-ion) cells in series (2S), to produce a nominal voltage of 8.4 V. Adding cells in a string only increases the voltage; the capacity remains the same. For higher currents, one or more cells can be connected in parallel, as shown in Figure 1b. The combined series and parallel configuration shown in Figure 1c enables design flexibility and achieves the required voltage and current ratings for an ultrasound scanner application with a standard cell size.

Figure 1 Voltage and Capacity

Scaling for a Li-ion Battery

Figure 1 Voltage and Capacity

Scaling for a Li-ion Battery3 Stackability Requirements for Battery Packs

Lithium batteries are dangerous. Depending on the battery capacity and number of cells, there are restrictions on their transportation by air—it is only permitted with a U.N. 38.3 certification according to the U.N. Manual of Tests and Criteria. International Air Transport Association Dangerous Goods Regulations specify the classification, marking, packing, labeling and documenting of dangerous shipments.

Designing a multibattery management system so that it is stackable helps meet shipping restrictions by enabling ultrasound scanner manufacturers to ship smaller-capacity batteries. By stacking these smaller batteries, designers can achieve a higher battery capacity which can provide longer back-up run times for equipment.