-

Isolated voltage sensing in AC motor drives

Isolated voltage sensing in AC motor drives

1 Introduction

Automotive and industrial end equipment such as motor drives, string inverters and onboard chargers operate at high voltages that are not safe for direct interaction with humans. Isolated voltage measurements help optimize operation and ensure the safety of humans by protecting them from the high-voltage circuit performing a function.

Designed for high performance, isolated amplifiers transfer voltage-measurement data across an isolation barrier. The criteria for determining isolated amplifier selection includes isolation specifications, the input voltage range, accuracy requirements, and how you plan to power the high-voltage side – something that the measurement’s location in the application will often influence.

This paper gives guidance on selecting the right isolated amplifier by evaluating three common voltage measurements in an AC motor-drive end equipment.

The first criterion is the required isolation specification; [1] covers the relevant isolation definitions. Texas Instruments (TI) isolated amplifiers and modulators are usually rated and certified at basic or reinforced isolation levels against device-level standards such as Deutsches Institut für Normung e.V. (DIN), Verband der Elektrotechnik Elektronik Informationstechnik e.V. (VDE) 0884-17, DIN European Norm (EN) International Electrotechnical Commission (IEC) 60747-17, and Underwriters Laboratories (UL) 1577. For additional information, see the device-specific data sheet and [2].

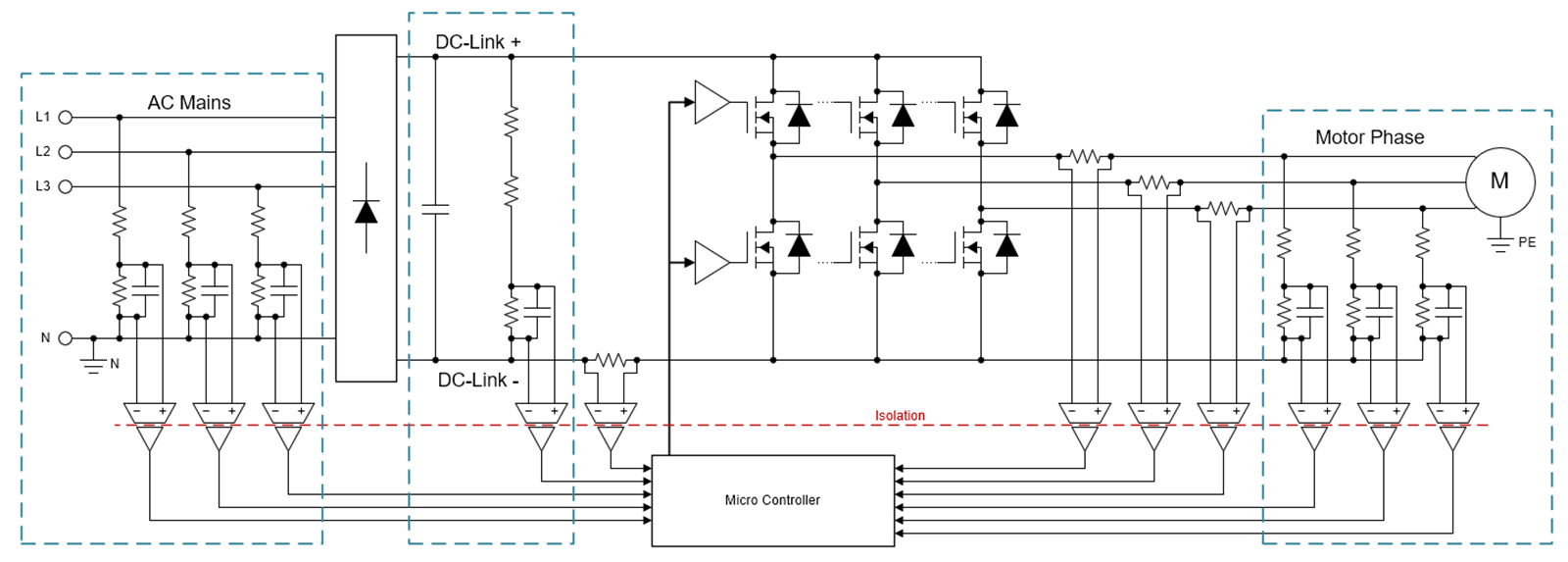

The selection of input voltage range, accuracy requirement and your high-voltage-side power method of choice depend on the location of the voltage node measured in the application. Figure 1-1 is a simplified block diagram of an AC motor drive with the three common locations for voltage measurements: the AC mains on the left, the DC link in the middle and the motor phase on the right. Isolated amplifiers are excellent devices for these measurements because of their high accuracy and ease of use.

Figure 1-1 An AC motor-drive

application.

Figure 1-1 An AC motor-drive

application.Shown on the left side of Figure 1-1, the AC mains input is often connected as a three-phase center-earthed power system with voltages that are 120VRMS/208 VRMS in the U.S. and 230 VRMS/400 VRMS in Europe. The required accuracy for this voltage measurement is typically low and not always needed. If you will be measuring the AC mains, consider devices with a bipolar high-impedance input such as TI’s AMC1350 or AMC3330. When making three-phase AC voltage measurements with respect to the neutral voltage, you can use a single isolated power supply for all three isolated amplifiers performing the measurement. When making three-phase AC voltage measurements phase-to-phase, consider using a device with an integrated C/DC converter to simply the design. Figure 1-2 shows the corresponding AMC3330 circuit diagram.

Figure 1-2 The AMC3330 isolated amplifier

with an internal DC/DC converter.

Figure 1-2 The AMC3330 isolated amplifier

with an internal DC/DC converter.Calculating the pulse-width modulation (PWM) duty cycle in a motor drive typically requires measurement of the DC link voltage shown in the middle of Figure 1-1 with an accuracy of 1% or better.

During braking operation, the DC link voltage increases and needs to be actively limited to protect the power stage by switching on a regenerative brake, for example. A low-latency measurement provides a faster reaction time to overvoltage events and enables the system to operate closer to the limits of its hardware, enabling tighter design margins and lower system costs. The DC link capacitance is usually several 100 µF, and determining whether the DC link capacitor has been properly discharged to a safe level before servicing the equipment requires accurate measurements at low voltages (<100 V). Furthermore, high-resolution AC ripple measurements allow for a phase-detection loss of the connected AC mains, potentially eliminating the need for a separate grid-side phase measurement. The frequency of the ripple voltage is either 360 Hz for a 60-Hz three phase mains voltage or 300 Hz for 50-Hz three-phase mains voltage, as there are six half waves being rectified. At a low load (when the motor is not spinning), the magnitude of the ripple voltage can be very low; thus, you may prefer a modulator for the highest resolution measurements. For more information on isolated amplifiers vs. isolated modulators, see [3]. Isolated amplifiers with unipolar input ranges such as TI’s AMC1351 (with a 0- to 5-V input range) or the AMC1311 (with a 0- to 2-V input range) are specifically designed for DC link voltage measurements. They require a local power supply referenced to DC- to power the high-voltage side such as the isolated transformer circuit shown in Figure 1-3. An alternative approach is to use a device such as the AMC3330 with an integrated DC/DC converter.

Figure 1-3 The AMC1311 isolated amplifier

with a discrete isolated transformer circuit.

Figure 1-3 The AMC1311 isolated amplifier

with a discrete isolated transformer circuit.Measuring the actual phase voltage rather than estimating the phase voltage based on the DC-link measurement and PWM duty cycle further improves the performance of sensorless AC motor drives. The direct measurement of the phase voltage gives a more precise result because it includes all losses in the system and the effect of PWM dead-time distortions. One method is to measure all three phases in respect to the DC– rail, with three unipolar-input isolated amplifiers and a single isolated power supply (as shown in Figure 1-3) to power the high side for all three isolated amplifiers.

An alternative method that saves on hardware cost is to measure only two phase-to-phase voltages and calculate the third. This method requires only two isolated amplifiers with a bipolar input range and minimal additional effort on the firmware side. The two measurements are made with respect to one of the phase voltages, which requires powering the isolated amplifiers from the floating high-side gate-driver supply of the top insulated gate bipolar transistor (IGBT), as shown in Figure 1-4. Devices with internal DC/DC converters such as the AMC3330 greatly simplify the circuit, enabling additional space savings and higher system efficiency.

Figure 1-4 The AMC1350 isolated amplifier

with a floating power supply.

Figure 1-4 The AMC1350 isolated amplifier

with a floating power supply.For each of these voltage measurements, a resistor divider must scale down the high-voltage node to match the input range of the isolated amplifier [4]. There are three common challenges when designing a resistor-divider circuit:

- The input bias current from the isolated amplifier that flows through the sensing resistor, creating an offset error.

- The sensing resistor is in parallel with the isolated amplifier’s input impedance, reducing the effective sensing resistance and creating a gain error. Additionally, the input impedance of the isolated amplifier can vary ±20% from device to device because of process variations and will appear as a gain error if unaccounted for.

- Temperature drift in both the resistor divider and input impedance of the isolated amplifier.

Selecting a device with high input impedance and negligible input bias current from TI’s line of isolated voltage sensing amplifiers significantly reduces the required effort to overcome these challenges; however, it is possible to design a high-accuracy voltage measurement circuit using a low-input-impedance isolated amplifier with input bias current [5].

Isolated amplifiers with a wider input range provide lower sensitivity to input noise and allow higher accuracy at low input levels. However, higher input voltage devices often have lower input impedance, as shown in Table 1, and require gain calibration to achieve highest level of accuracy. A high-impedance-input device provides higher uncalibrated accuracy and reduces design effort. For more information when comparing data-sheet accuracy and the typical and maximum error calculations of TI isolated amplifiers, see [6].

| Device | Input Voltage Range | Input Impedance | Integrated DC/DC | Automotive Available |

|---|---|---|---|---|

| AMC1211A-Q1 | 0 V to 2 V | 1 GΩ | No | Yes |

| AMC1311/B | 0 V to 2 V | 1 GΩ | No | Yes |

| AMC1411 | 0 V to 2 V | 1 GΩ | No | Yes |

| AMC1351 | 0 V to 5 V | 1.25 MΩ | No | Yes |

| AMC3330 | ±1 V | 1 GΩ | Yes | Yes |

| AMC1350 | ±5 V | 1.25 MΩ | No | Yes |

| ISO224A/B | ±12 V | 1.25 MΩ | No | No |

2 Conclusion

Texas Instrument's wide selection of isolated amplifiers for high-impedance voltage measurements allows you make the right trade-off between cost, performance, ease of implementation, and board space to optimize the design to your requirements and meet industry isolation performance standards.

3 References

- Texas Instruments: Design considerations for isolated current sensing

- Texas Instruments: TUEV Technical Report No. 713203936

- Texas Instruments: Comparing Isolated Amplifiers and Isolated Modulators

- Texas Instruments: ±480-V isolated voltage-sensing circuit with differential output

- Texas Instruments: Isolated Voltage-Measurement Circuit With ±250-mV Input and Differential Output

- Texas Instruments: Isolated Amplifier Voltage Sensing Excel Calculator

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you permission to use these resources only for development of an application that uses the TI products described in the resource. Other reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims, damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2022, Texas Instruments Incorporated