SNVSB35C May 2018 – November 2024 LM26420-Q1

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Pin Configuration and Functions

- 5 Specifications

- 6 Detailed Description

-

7 Application and Implementation

- 7.1 Application Information

- 7.2 Typical Applications

- 7.3 Power Supply Recommendations

- 7.4 Layout

- 8 Device and Documentation Support

- 9 Revision History

- 10Mechanical, Packaging, and Orderable Information

7.2.1.2.3 Input Capacitor Selection

The input capacitors provide the AC current needed by the nearby power switch so that current provided by the upstream power supply does not carry a lot of AC content, generating less EMI. To the buck regulator in question, the input capacitor also prevents the drain voltage of the FET switch from dipping when the FET is turned on, therefore, providing a healthy line rail for the LM26420-Q1 to work with. Because typically most of the AC current is provided by the local input capacitors, the power loss in those capacitors can be a concern. In the case of the LM26420-Q1 regulator, because the two channels operate 180° out of phase, the AC stress in the input capacitors is less than if operated in phase. The measure for the AC stress is called input ripple RMS current. TI strongly recommends that at least one 10-µF ceramic capacitor be placed next to each of the VIND pins. Bulk capacitors such as electrolytic capacitors or OSCON capacitors can be added to help stabilize the local line voltage, especially during large load transient events. As for the ceramic capacitors, use X7R or X5R types. They maintain most of the capacitance over a wide temperature range. Try to avoid sizes smaller than 0805. Otherwise significant drop in capacitance can be caused by the DC bias voltage. See the Section 7.2.1.2.4 section for more information. The DC voltage rating of the ceramic capacitor must be higher than the highest input voltage.

Capacitor temperature is a major concern in board designs. While using a 10-µF or higher MLCC as the input capacitor is a good starting point, check the temperature in the real thermal environment to make sure the capacitors are not overheated. Capacitor vendors can provide curves of ripple RMS current versus temperature rise based on a designated thermal impedance. In reality, the thermal impedance can be very different, so checking the capacitor temperature on the board is always a good idea

Because the duty cycles of the two channels can overlap, calculation of the input ripple RMS current is a little tedious — use Equation 16:

where

- I1 is the maximum output current of Channel 1

- I2 is the maximum output current of Channel 2

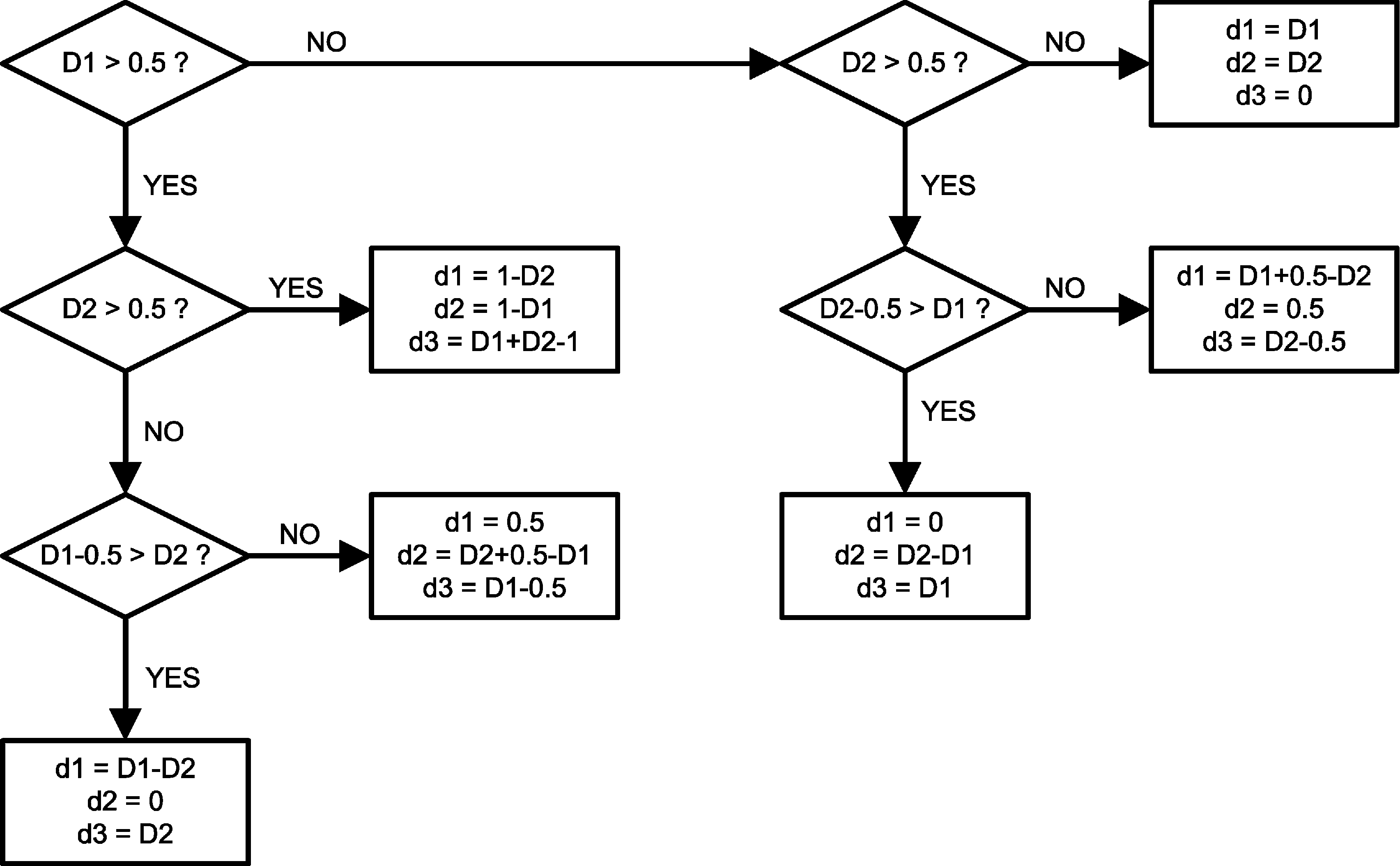

- d1 is the non-overlapping portion of the duty cycle, D1, of Channel 1

- d2 is the non-overlapping portion of the duty cycle, D2, of Channel 2

- d3 is the overlapping portion of the two duty cycles

- Iav is the average input current

Iav = I1 × D1 + I2 × D2. To quickly determine the values of d1, d2, and d3, refer to the decision tree in Figure 7-9. To determine the duty cycle of each channel, use D = VOUT / VIN for a quick result or use Equation 17 for a more accurate result.

where

- RDC is the winding resistance of the inductor

Example:

- VIN = 5 V

- VOUT1 = 3.3 V

- IOUT1 = 2 A

- VOUT2 = 1.2 V

- IOUT2 = 1.5 A

- RDS = 170 mΩ

- RDC = 30 mΩ

IOUT1 is the same as I1 in the input ripple RMS current equation and IOUT2 is the same as I2.

First, find out the duty cycles. Plug the numbers into the duty cycle equation and get D1 = 0.75, and D2 = 0.33. Next, follow the decision tree in Figure 7-9 to find out the values of d1, d2, and d3. In this case, d1 = 0.5, d2 = D2 + 0.5 – D1 = 0.08, and d3 = D1 – 0.5 = 0.25. Iav = IOUT1 × D1 + IOUT2 × D2 = 1.995 A. Plug all the numbers into the input ripple RMS current equation and the result is IIR(rms) = 0.77 A.

Figure 7-9 Determining D1, D2, and D3

Figure 7-9 Determining D1, D2, and D3