SPRACV2 November 2020 AWR1843 , AWR2243

- Trademarks

- 1Introduction

- 2Cascade Incoherence Sources and Mitigation Strategies

-

3Enabling Cascade Coherence and Improved Phase

Performance

- 3.1 High-Level Summary

- 3.2 Saving RF INIT Calibration Results at Customer Factory

- 3.3 Corner Reflector-Based Offsets Measurement at Customer Factory

- 3.4 Restoring Customer Calibration Results In-Field

- 3.5

Host-Based Temperature Calibrations

In-Field

- 3.5.1 Disabling AWR Devices’ Autonomous Run Time Calibrations

- 3.5.2 Enabling Host-Based Temperature Calibrations of Inter-Channel Imbalances

- 3.5.3 Switching of DSP Imbalance Data

- 3.5.4

Enabling TX Phase Shifter’s Host-Based

Temperature Calibrations

- 3.5.4.1 Estimating TX Phase Shift Values at Any Temperature

- 3.5.4.2 Temperature Correction LUTs for AWR1843TX Phase Shifter

- 3.5.4.3 Temperature Correction LUTs for AWR2243 TX Phase Shifter

- 3.5.4.4 Restoring TX Phase Shift Values – Format Conversion

- 3.5.4.5 Restoring TX Phase Shift Values – Transition Timing and Constraints

- 3.5.4.6 Typical Post-Calibration TX Phase Shifter Accuracies

- 3.5.4.7 Correcting for Temperature Drift While Sweeping Across Phase Settings

- 3.5.4.8 Amplitude Stability Across Phase Shifter Settings

- 3.5.4.9 Impact of Customer PCB’s 20-GHz Sync Path Attenuation on TX Phase Shifters

- 3.5.5 Ambient and Device Temperatures

- 4Concept Illustrations

- 5Miscellaneous (Interference, Gain Variation, Sampling Jitter)

- 6Conclusion

- A Appendix

3.2.2 TX Phase Shifter Calibration and Saving Results at Customer Factory

The TX phase shifters can have inherent errors which have process and temperature variation. There are two possible methods to mitigate the process variation (temperature variation is addressed in later sections).

- Using RF INIT TX phase shift calibrations.

- This is described in this section.

- This option requires the TX phase shifter calibration in RF INIT to be enabled.

- Using customer factory corner reflector.

- This is described in the offsets measurement section later in this document.

- This option requires the TX phase shifter calibration in RF INIT to be disabled.

The AWR devices’ self-calibration of TX phase shifters gets executed in the process of RF INIT. These use the device’s internal TX loopback paths and algorithms. The results from these may be used as the baseline for all in-field TX phase shifter error mitigation.

The message AWR PHASE SHIFTER CAL DATA SAVE SB can be used to save the data into the sensor’s non-volatile memory, for each TX in the cascade. This data can be restored to the AWR device and that part is explained later in the document.

If deriving the phase shifter calibration values from the devices’ internal RF INIT TX phase shifter calibrations in customer factory:

The user should account for the API’s phase indexing format, which may differ across TXs; refer to Section 7.5.

The arrays Factory Measured Phase Shift ArrayRF INIT TX PS Cal,TXm (0 to 63) collected at factory temperature are necessary for restoring back to the device (explained later in this document). Example values for the Measured Phase Shift Array of Equation 1: [0, 5, 11, … 356] degrees, corresponding to [0, 5.625, 11.25, … 354.375] degree phase shifter settings. These correspond to INL error values of [0, 0.625, 0.25, … –1.625] degree, i.e. the deviation from ideal expectations. The term INL error refers to Integrated Non Linearity error (it is used in many places in this note).

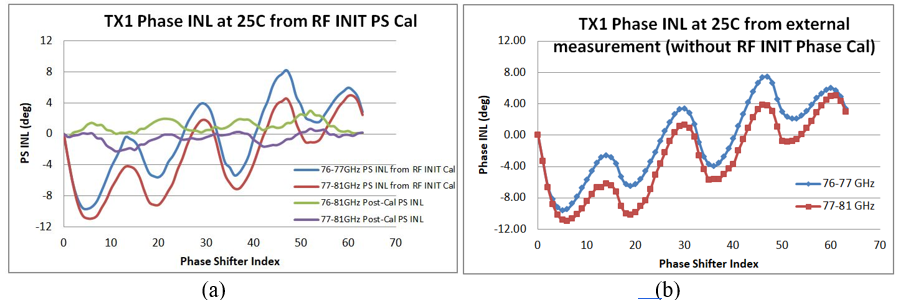

The raw analog TX phase shifter’s INL as measured by internal RF INIT calibration at 25C is represented in Figure 3-1(a). The post-calibration residual PS INL is also represented in Figure 3-1(a) to illustrate the efficacy of RF INIT TX phase shift calibration. Further, Figure 3-1(b) illustrates the raw analog TX phase shifter’s INL as measured using external/independent method. The graphs in Figure 3-1(a) and Figure 3-1(b) are fairly matching, illustrating the efficacy of internal calibration. These have been obtained in TI lab evaluation of a few nominal process based devices.

Figure 3-1 Phase Shifter INL Plots at 25C for AWR2243 nominal devices information: (a)

With internal RF INIT phase shifter calibration (b) With external waveguide

loopback based measurements

Figure 3-1 Phase Shifter INL Plots at 25C for AWR2243 nominal devices information: (a)

With internal RF INIT phase shifter calibration (b) With external waveguide

loopback based measurementsThe above addressed the mitigation of process variation, and a strategy to mitigate temperature drift effect is recommended later in this note.